Rolling level thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polymers, can solve the problems of large loss of additives, unfavorable industrial production, and increase the difficulty of TPU calendering processing, etc., to achieve the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

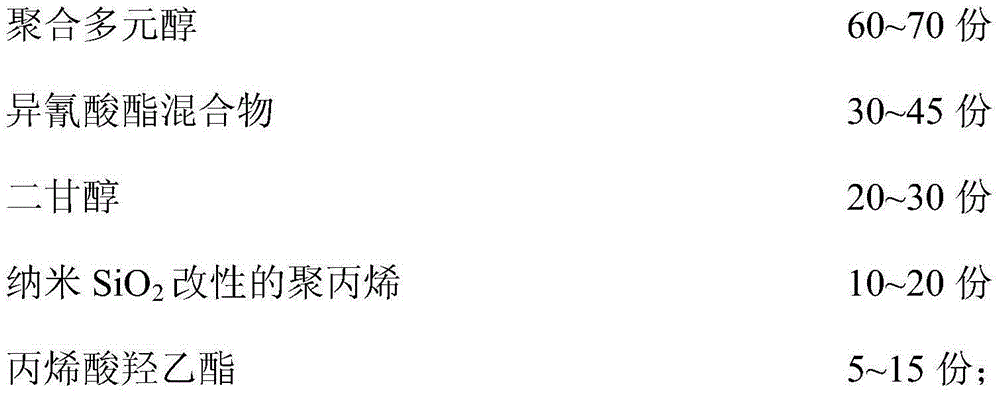

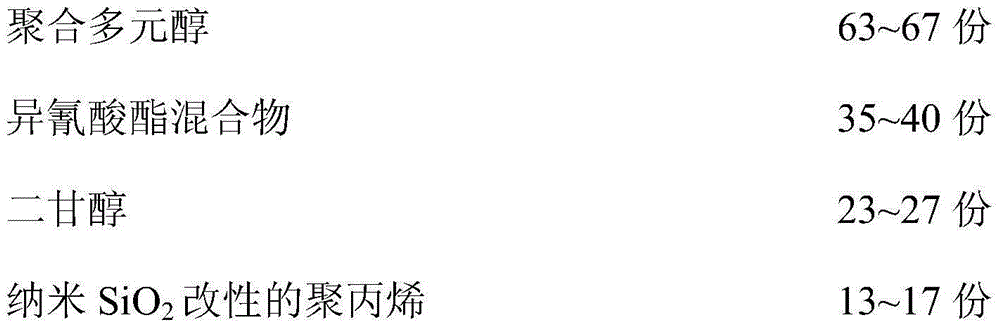

Method used

Image

Examples

Embodiment 1

[0062] (1) Preparation of nano-SiO 2 Modified Polypropylene:

[0063] Add the mixture of 100 parts of polypropylene and 15 parts of dicumyl peroxide into the twin-screw extruder, and set the temperature of the feeding section of the twin-screw extruder, the temperature of the mixing section, the temperature of the extrusion section and the temperature of the machine head to 150 ℃, 150℃, 150℃ and 135℃, etc., after it melts, add 25 parts of nano-SiO 2 Perform melt grafting reaction to obtain nano-SiO 2 Modified polypropylene.

[0064] (2) Preparation of thermoplastic polyurethane elastomer

[0065] 65 parts of polymer polyol (wherein, the number average molecular weight of polymer polyol is 1700, the mass ratio of polytetrahydrofuran diol and 1,4-butylene adipate diol is 5:1), 25 parts Add diethylene glycol and 10 parts of hydroxyethyl acrylate into the container, and dehydrate under 55°C vacuum-0.3kPa under the stirring condition of 1100r / min to obtain mixture A; The mass ...

Embodiment 2

[0068] (1) Preparation of nano-SiO 2 Modified Polypropylene:

[0069] Add the mixture of 100 parts of polypropylene and 20 parts of dicumyl peroxide into the twin-screw extruder, and set the temperature of the feeding section, the mixing section, the extrusion section and the head temperature of the twin-screw extruder to 140 ℃, 140℃, 140℃ and 130℃, etc., after it melts, add 10 parts of nano-SiO 2 Perform melt grafting reaction to obtain nano-SiO 2 Modified polypropylene.

[0070] (2) Preparation of thermoplastic polyurethane elastomer

[0071] 63 parts of polymer polyol (wherein, the number average molecular weight of polymer polyol is 1500, the mass ratio of polytetrahydrofuran diol and 1,4-butanediol adipate diol is 6:1), 23 parts Add diethylene glycol and 7 parts of hydroxyethyl acrylate into the container, and dehydrate under 50°C vacuum-0.2kPa under the stirring condition of 1200r / min to obtain mixture A; The mass ratio of base diisocyanate is 5:1) after being heate...

Embodiment 3

[0074] (1) Preparation of nano-SiO 2 Modified Polypropylene:

[0075] Add a mixture of 100 parts of polypropylene and 30 parts of dicumyl peroxide into the twin-screw extruder, and set the temperature of the feeding section, the mixing section, the extrusion section and the head temperature of the twin-screw extruder to 160 ℃, 160℃, 160℃ and 140℃, etc., after it melts, add 20 parts of nano-SiO 2 Perform melt grafting reaction to obtain nano-SiO 2 Modified polypropylene.

[0076] (2) Preparation of thermoplastic polyurethane elastomer

[0077] With 67 parts of polymeric polyol (wherein, the number average molecular weight of polymeric polyol is 2000, the mass ratio of polytetrahydrofuran diol and 1,4-butylene adipate diol is 3:1), 27 parts Add diethylene glycol and 13 parts of hydroxyethyl acrylate into the container, and dehydrate at 60°C under vacuum at 0.4kPa under the stirring condition of 1000r / min to obtain mixture A; The mass ratio of base diisocyanate is 2:1) after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com