Heating type screw conveyor

The technology of a screw conveyor and a screw body is applied in the field of material transportation equipment, which can solve the problems of inability to meet the production process, material temperature loss, etc., and achieve the effects of improving heat exchange efficiency, effective temperature control, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

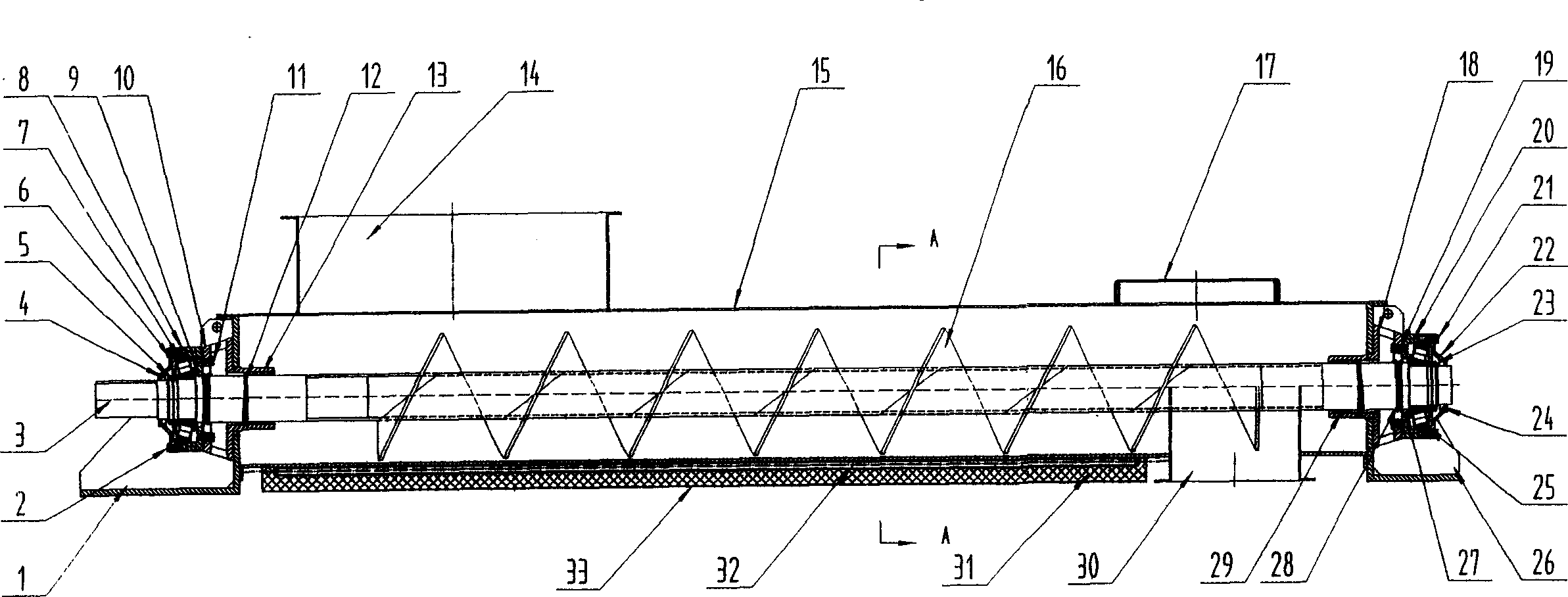

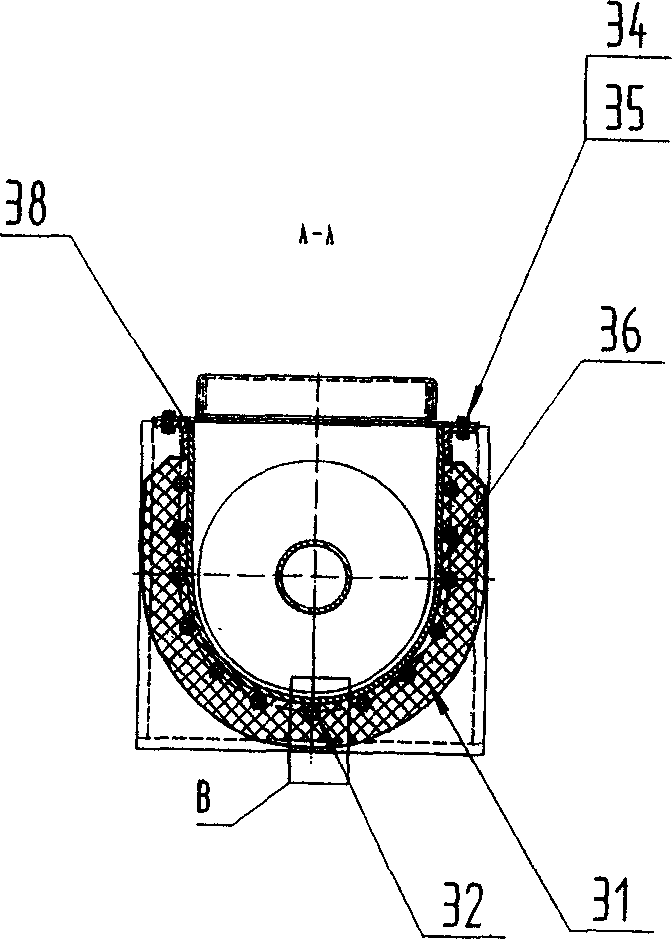

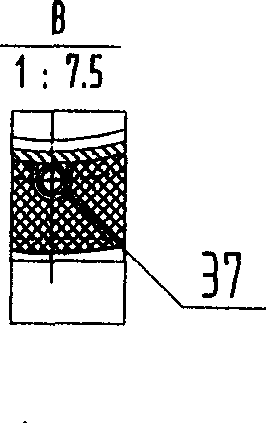

[0013] The present invention mainly consists of front bracket 1, bolt 2, left end extension shaft 3, sealing ring 4, round nut 5, bearing cover 6, bearing 7, bearing seat 8, sealing ring 9, left sealing support 10, bolt 11, cylindrical spring 12. Gasket 13, material inlet 14, cover 15, spiral body 16, inspection hole 17, right seal bracket 18, bolt 19, bearing seat 20, bolt 21, bearing cover 22, round nut 23, sealing ring 24, bearing 25 , right sealing bracket 26, sealing ring 27, discharge port 30, insulation cotton 31, heat carrier pipe 32, metal covering 33, bolt 34, nut 35, pipe fixing frame 37, screw conveyor housing 38 and other components.

[0014] The present invention mainly adopts left support 1, right support 26 to be installed in screw conveyor housing 38 two ends (welding) respectively. The left sealing bracket 10 is bolted to the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com