Antibacterial PP spun-bonded non-woven fabric and preparation method thereof

A technology of spunbond non-woven fabrics and raw materials, which is applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of no antibacterial properties, poor moisture absorption and ventilation performance, low comfort in use, etc., and achieve good moisture absorption. Breathable performance, long-lasting antibacterial effect, skin-friendly and hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

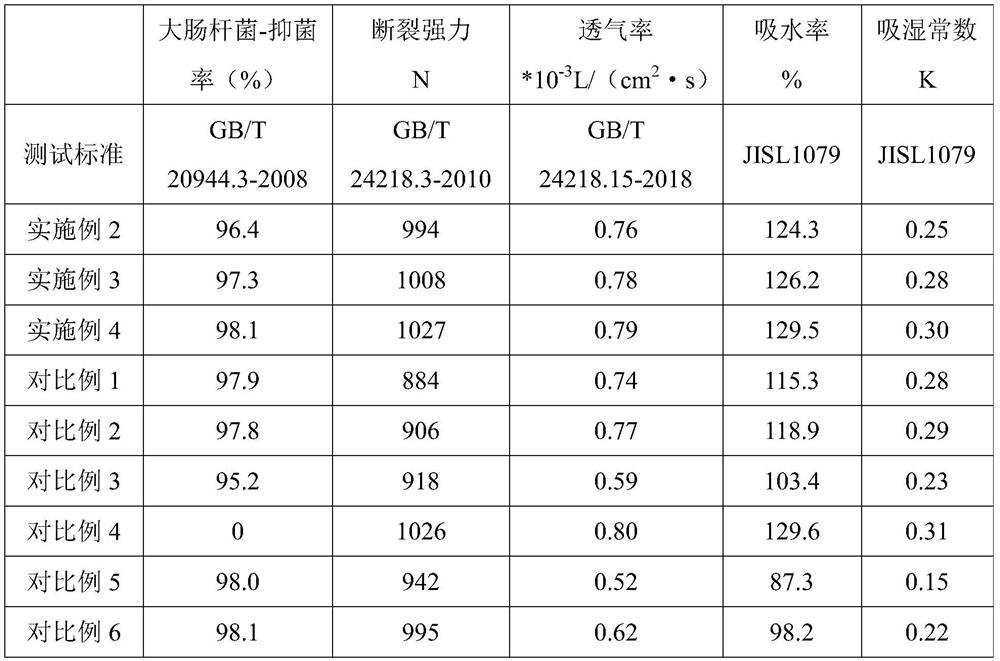

Examples

Embodiment 1

[0052] An antibacterial PP spunbonded nonwoven fabric, said antibacterial PP spunbonded nonwoven fabric is made of raw materials comprising the following parts by weight:

[0053] 55-65 parts of polypropylene,

[0054] 30-37 parts of ethylene-methyl methacrylate copolymer,

[0055] 16-20 parts of polyethylene glycol monomethyl ether,

[0056] 2-4 parts of maleic anhydride grafted polypropylene,

[0057] 3-4.2 parts of large-pore hollow silica nanoparticles,

[0058] 2.6-3.2 parts of nano silver-loaded titanium dioxide,

[0059] Filling 5 to 8 parts.

[0060] In this embodiment, the antibacterial PP spunbonded nonwoven fabric is preferably, but not limited to, made of raw materials including the following parts by weight:

[0061] 60 parts of polypropylene,

[0062] 33.5 parts of ethylene-methyl methacrylate copolymer,

[0063] 18 parts of polyethylene glycol monomethyl ether,

[0064] 3 parts of maleic anhydride grafted polypropylene,

[0065] 3.6 parts of large-pore ...

Embodiment 2

[0079] An antibacterial PP spunbonded nonwoven fabric, said antibacterial PP spunbonded nonwoven fabric is made of raw materials comprising the following parts by weight:

[0080] 55 parts of polypropylene,

[0081] 30 parts of ethylene-methyl methacrylate copolymer,

[0082] 16 parts of polyethylene glycol monomethyl ether,

[0083] Maleic anhydride grafted polypropylene 2 parts,

[0084] 3 parts of hollow silica nanoparticles with large pores,

[0085] Nano silver loaded titanium dioxide 2.6 parts,

[0086] Filling 5 parts.

[0087] In this embodiment, the antibacterial PP spunbonded nonwoven fabric also includes the following raw materials in parts by weight: anti-ultraviolet light agent: 2.5 parts.

[0088] In this embodiment, the molar ratio of monomer unit ethylene and methyl methacrylate in the ethylene-methyl methacrylate copolymer is 1:0.32.

[0089] In this embodiment, the particle diameter of the large-diameter hollow silica nanoparticles is 150 nm, and the po...

Embodiment 3

[0098] An antibacterial PP spunbonded nonwoven fabric, said antibacterial PP spunbonded nonwoven fabric is made of raw materials comprising the following parts by weight:

[0099] 65 parts of polypropylene,

[0100] 37 parts of ethylene-methyl methacrylate copolymer,

[0101] 20 parts of polyethylene glycol monomethyl ether,

[0102] 4 parts of maleic anhydride grafted polypropylene,

[0103] 4.2 parts of large-pore hollow silica nanoparticles,

[0104] 3.2 parts of nano silver-loaded titanium dioxide,

[0105] Filling 8 parts.

[0106] In this embodiment, the antibacterial PP spunbonded nonwoven fabric also includes the following raw materials in parts by weight: anti-ultraviolet light agent: 3.5 parts.

[0107] In this embodiment, the molar ratio of monomer unit ethylene and methyl methacrylate in the ethylene-methyl methacrylate copolymer is 1:0.36.

[0108] In this embodiment, the particle diameter of the large-diameter hollow silica nanoparticles is 170 nm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com