High-strength inorganic artificial stone and manufacturing method thereof

A manufacturing method and artificial stone technology, applied in the field of building materials, can solve the problems of safety and health hazards and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

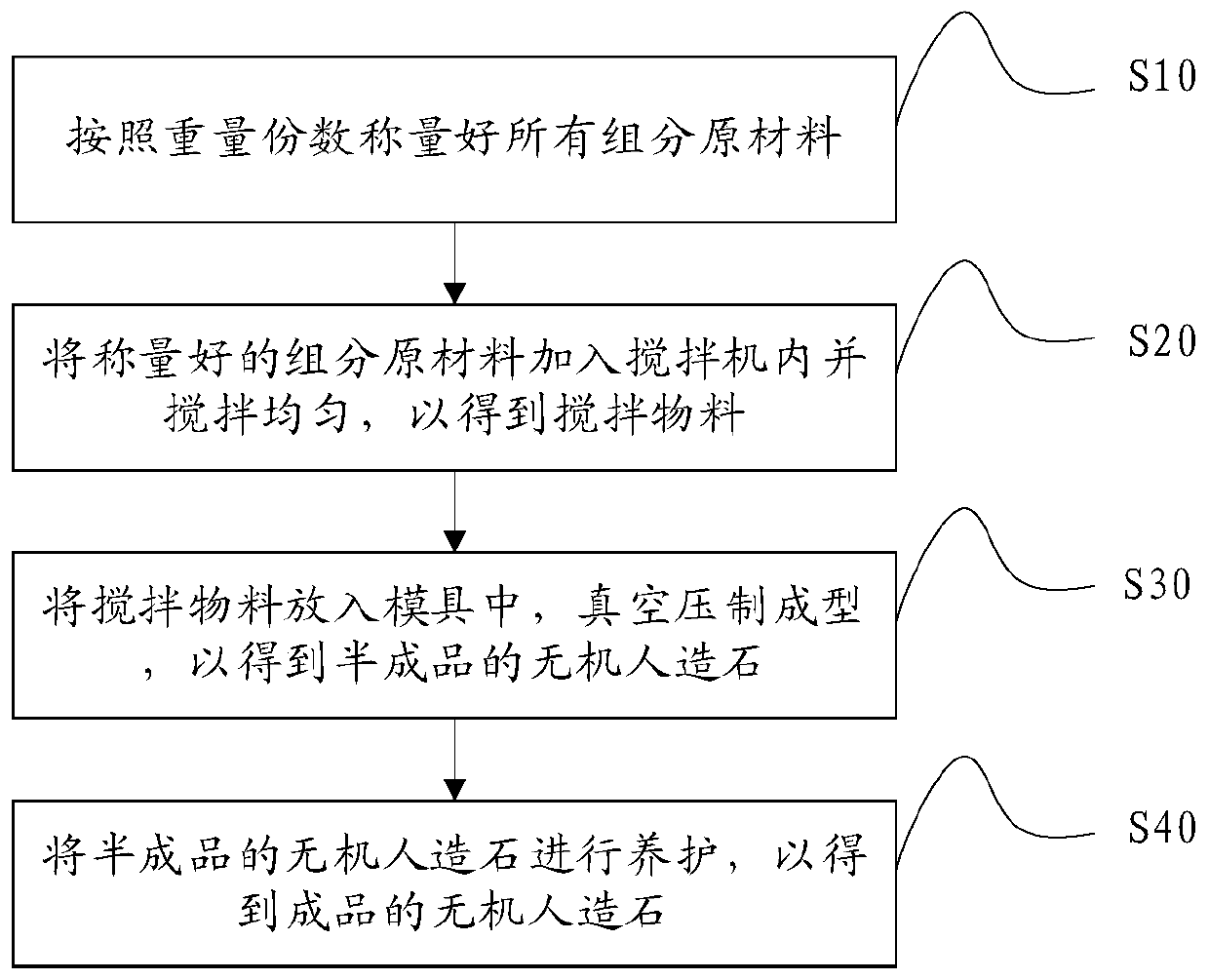

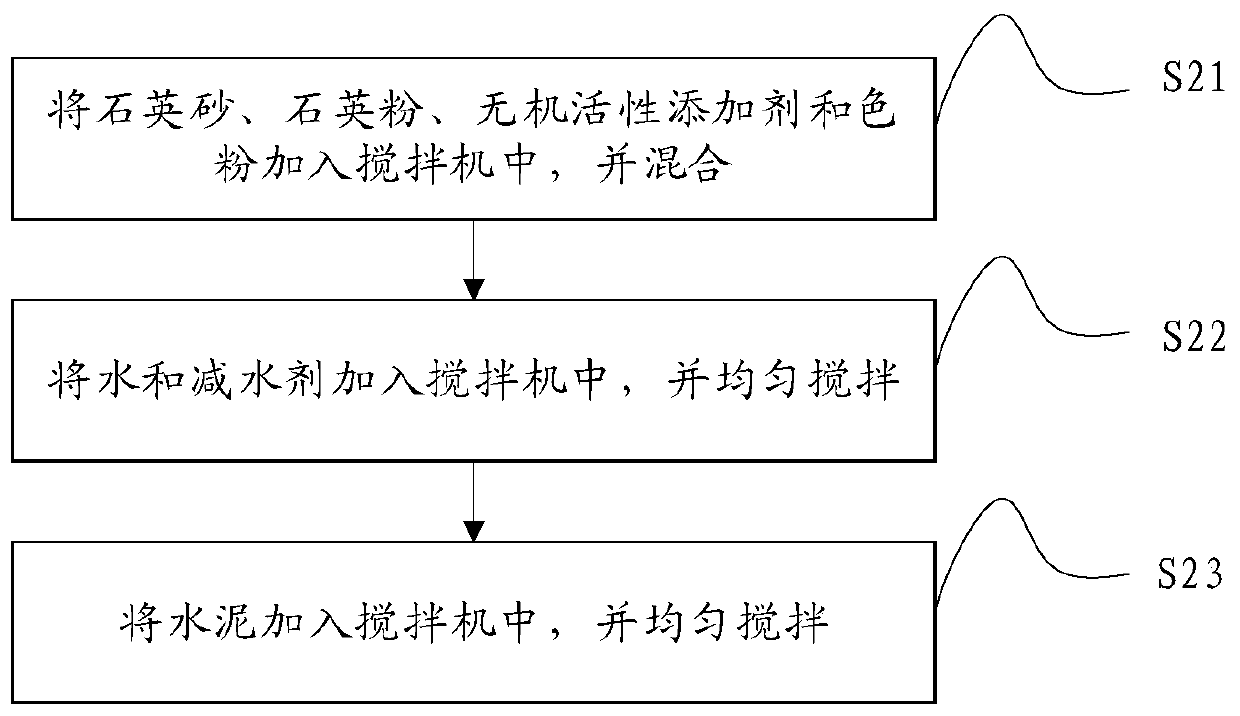

Method used

Image

Examples

Embodiment 1

[0035] The present invention proposes a high-strength inorganic artificial stone. In parts by weight, the high-strength inorganic artificial stone comprises the following components: 60-70 parts of quartz sand, 5-10 parts of quartz powder, 22-25 parts of cement, and an inorganic active additive of 2.5-4 parts, 0.5-1.5 parts of water reducer, 2-4 parts of water.

[0036] The above-mentioned quartz sand, quartz powder, cement, inorganic active additives, water reducing agent and water are all inorganic raw materials. The high-strength inorganic artificial stone of the present invention is prepared by using all inorganic raw materials, and no organic materials are used in the whole process. The preparation of artificial stone can effectively avoid the pollution of the environment when artificial stone is used. For example, organic raw materials such as glue, resin and organic toughening materials are not used, which can effectively reduce the emission of toxic gases; and by using ...

Embodiment 2

[0050] The present invention proposes a high-strength inorganic artificial stone. In parts by weight, the high-strength inorganic artificial stone comprises the following components: 60-70 parts of quartz sand, 5-10 parts of quartz powder, 22-25 parts of cement, and an inorganic active additive of 3-4 parts, 0.5-1.5 parts of water reducer, 2-4 parts of water.

[0051] Compared with Example 1, the inorganic active additive used in this example is 3-4 parts by weight. The proportions by weight and specific materials of the remaining inorganic raw materials in Example 2 are the same as those in Example 1, and Example 1 may be referred to.

[0052] The high-strength inorganic artificial stone of the present invention uses all inorganic raw materials to prepare inorganic artificial stone, and does not use organic materials to prepare artificial stone in the whole process, effectively preventing artificial stone from polluting the environment during use, such as not using glue and r...

Embodiment 3

[0054] The present invention also proposes a high-strength inorganic artificial stone, which comprises the following components in parts by weight: 60-70 parts of quartz sand, 5-10 parts of quartz powder, 22-25 parts of cement, and inorganic active additives 3.5 parts, 0.5-1.5 parts of water reducer, 2-4 parts of water.

[0055] Compared with Example 1, the inorganic active additive used in this example is 3.5 parts by weight. The proportions by weight and specific materials of the remaining inorganic raw materials in Example 3 are the same as those in Example 1, so refer to Example 1.

[0056] The high-strength inorganic artificial stone of the present invention uses all inorganic raw materials to prepare inorganic artificial stone, and does not use organic materials to prepare artificial stone in the whole process, effectively preventing artificial stone from polluting the environment during use, such as not using glue and resin Organic raw materials such as organic toughen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com