Assembled type telescopic curtain supporting rod

An assembled and curtain technology, which is applied to window decorations, curtain hanging devices, household appliances, etc. It can solve problems such as inaccurate measurement, inconvenient transportation, and large length of curtain poles to ensure load-bearing capacity and flexural resistance The effect of strength, portability and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

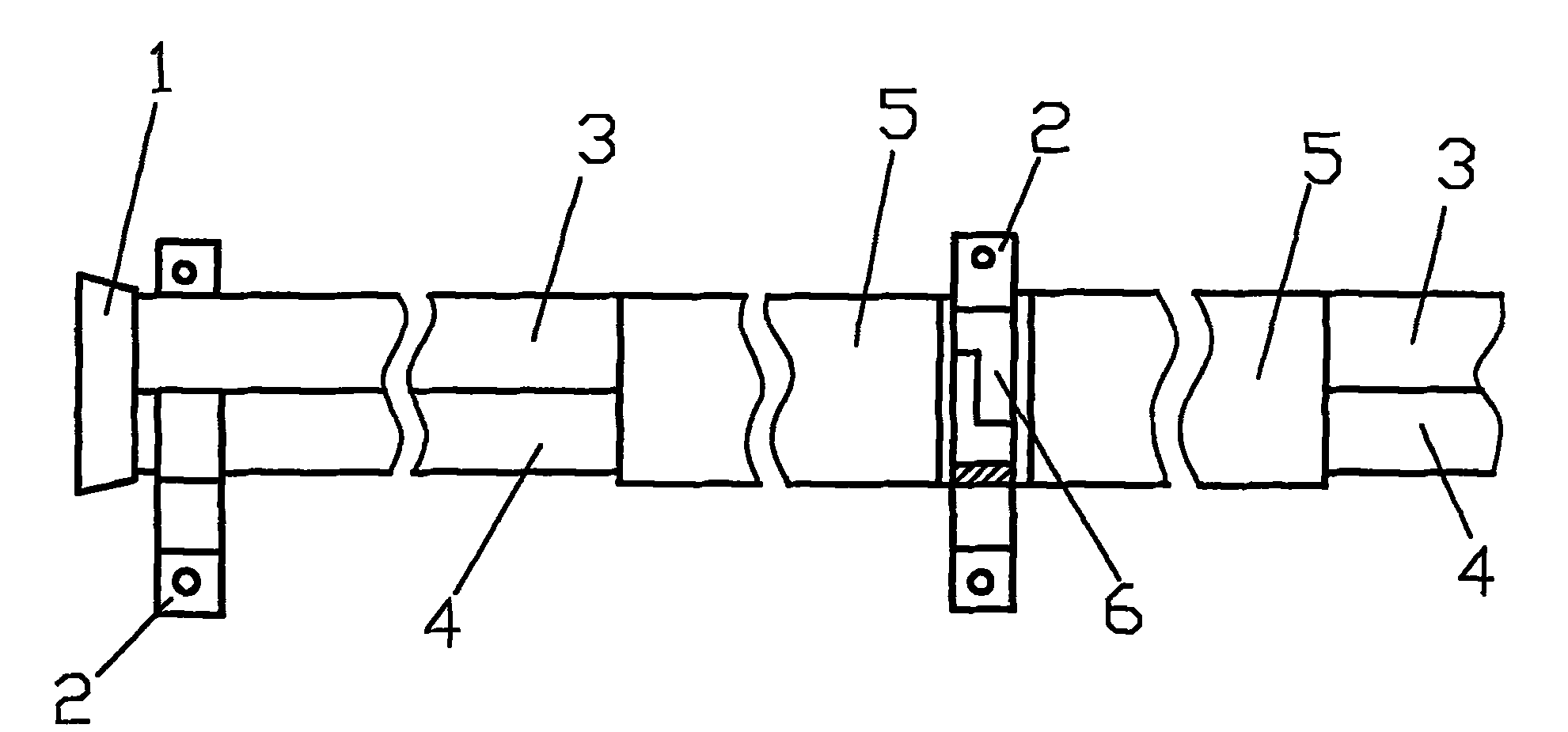

[0024] Such as figure 1 As shown, the assembled retractable curtain pole is composed of one or two sets of telescopic curtain pole groups and three curtain pole fixing frames 2; it is characterized in that: the telescopic curtain pole group consists of two telescopic curtain pole groups Composed of rods, the telescopic curtain stays are symmetrical to each other with the butt joint 6 fastened at the ends; The inner rod 4 is set inside the main rod 5, and the end of the inner rod 4 is equipped with a decorative end 1;

[0025] Such as Figure 8 , 9 As shown, the part-the end of the curtain pole fixing frame 2 is a fixing seat 22, and the two ends of the fixing seat 22 are prefabricated with fixing screw holes 23; one side of the fixing seat 22 is prefabricated with a curtain bracket 20 and a screen bracket 21 ; In the curtain bracket 20 and the screen bracket 21, one or two groups of telescopic curtain pole groups are selected and installed according to the actual needs of c...

Embodiment 2

[0029] Such as Figure 10 , 14 , 15, the assembled retractable curtain rod is composed of one or two groups of telescopic curtain rod groups and three curtain rod fixing frames 2; it is characterized in that:

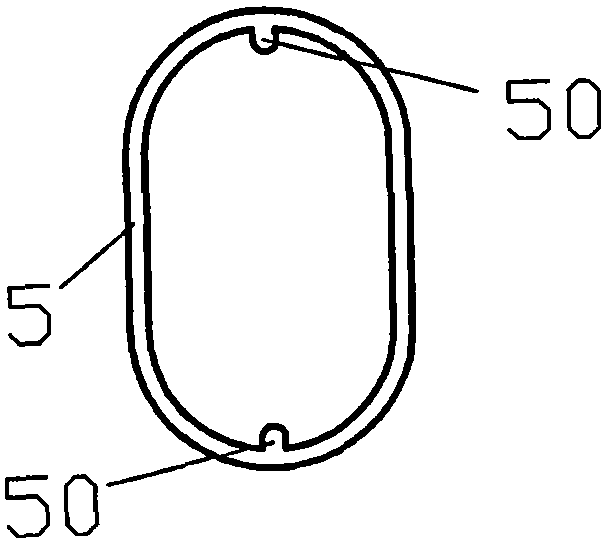

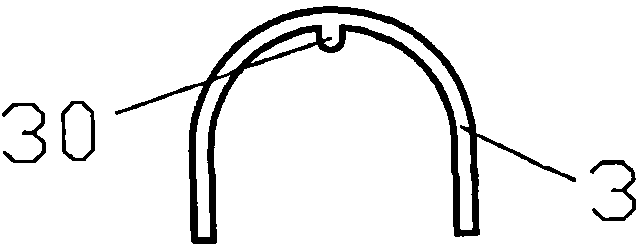

[0030] The telescopic curtain stay group is composed of two telescopic curtain stays, and the butt joints 6 that are fastened at the ends are symmetrical to each other between the telescopic curtain stays; The inner rod 41 in the groove, the attached rod 31 on the convex rail, the butt joint 6, and the decorative end 1; ; The upper part of the groove inner rod 41 is fitted with the attached rod 31 on the convex rail, and the other end of the net inner wall main rod 51 is equipped with a butt joint 6;

[0031] Such as Figure 11 , 12 , shown in 13, the components—clean inner wall main rod 51, groove inner rod 41, and convex rail upper attachment rod 31 are all made of prefabricated profiles——aluminum alloy profiles or other metal profiles or rigid PVC profiles, accor...

Embodiment 3

[0035] Such as Figure 15 As shown, in the curtain bracket 20, one group of telescopic curtain struts is installed. This can be used to hang single layer curtains. The telescopic curtain pole set can be any of the methods listed in Embodiment 1 or Embodiment 2.

[0036] If, the structure and the docking method of the butt joint 6 are changed to spiral butt joint, or the method of inserting butt joint; Rod 5, inner rod 4 (as in embodiment 1) or main rod 51 on the clear inner wall and grooved inner rod 41 (as in embodiment 2) are made into a circular tube structure, and upper attached rod 3 and upper attached rod 31 on the convex rail are made into The arc structure, its installation method and structure remain unchanged, can also realize the object of the present invention. Changes in such details also fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com