Composite bipolar plate for PEM (proton exchange membrane) fuel battery and preparation method thereof

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, fuel cell parts, battery electrodes, etc., can solve the adverse effects of composite bipolar plates on air tightness and bending strength, and increase the molding or extrusion process Difficulty, affecting the forming efficiency of composite bipolar plates and production costs, etc., to achieve low-cost mass production, good air tightness, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

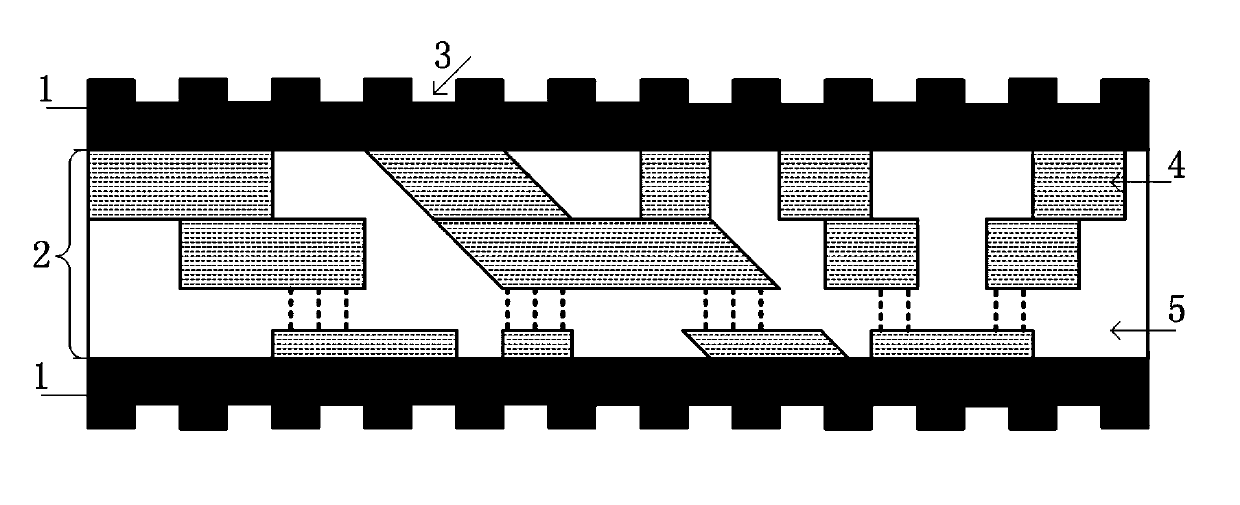

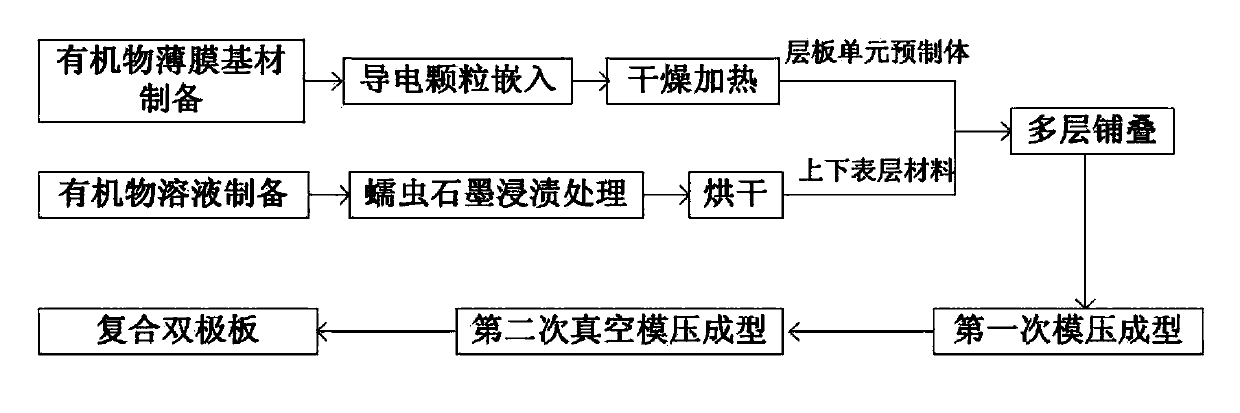

[0031] Dissolve the liquid phenolic resin in absolute ethanol with a mass concentration of 80%, prepare a phenolic resin solution with a mass concentration of 70%, then put the worm graphite into the above organic solvent for 30min, and then put it in a vacuum at 50°C and 98KPa Dry for 60min. Get 50 grams of above-mentioned organic solvents and inject it on the rotary table with a rotation speed of 1000 revs / min to obtain a thickness of 0.1mm phenolic resin film substrate; spray 250 mesh flake graphite into the phenolic resin film under the action of 0.8MPa gas pressure, Vacuum drying at 50° C. and 98 KPa for 60 minutes to obtain a laminate unit preform, repeat the above process 10 times, and obtain 10 laminate unit preforms. Lay up the lower surface material, 10 laminate unit preforms, and the upper surface material in the mold, first press at 80°C and 5MPa for 5 minutes, and then keep at 130°C and 30MPa for 30 minutes under vacuum conditions, the vacuum degree is controlled ...

Embodiment 2

[0033]Using epoxy resin as the organic substrate, acetone with a mass concentration of 75% as a solvent, prepare an epoxy resin solution with a mass concentration of 60%, put worm graphite into the epoxy resin solution for 90min, and heat it under 100μm infrared rays at 60°C Dry for 10 minutes, and dry for 120~150 minutes. Inject 60 grams of epoxy resin solution onto a rotary table with a rotation speed of 1200 rpm to obtain an epoxy resin film substrate with a thickness of 0.08 mm; spray 300 mesh flake graphite onto the epoxy resin under the action of an external air pressure of 1.0 MPa In the film substrate, dry under 100 μm infrared rays at 60° C. for 10 minutes to obtain a laminate unit preform, repeat the above process 5 times, and obtain 5 laminate unit preforms. Lay up the lower surface material, 5 laminate unit preforms, and the upper surface material in the mold, first hot press at 160°C and 3MPa for 15 minutes, then hold the pressure at 240°C and 30MPa for 20 minutes...

Embodiment 3

[0035] Using polyvinyl chloride as the organic substrate, with a mass concentration of 95% cyclohexane as the solvent, prepare an epoxy resin solution with a concentration of 60%, immerse the worm graphite in the organic solution for 90min, 200μm infrared rays, and dry at 60°C 10min. Inject 65 grams of polyvinyl chloride solution onto a rotary table with a rotation speed of 1200 rpm to obtain a 0.2mm thick epoxy resin film substrate; 250 mesh flake graphite and 300 mesh copper powder (The mass ratio of the two is 3:1) sprayed into the epoxy resin film substrate, 200μm infrared rays, and dried at 60°C for 10 minutes to obtain a laminate unit preform. Repeat the above process 3 times to obtain 3 laminate unit preforms . Lay up the lower surface material, multiple laminate unit preforms, and upper surface material in the mold, first hot press at 100°C and 3MPa for 5min, then hold the pressure at 150°C and 30MPa for 20min, vacuum The pressure is controlled below 200Pa. The meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com