Intelligent large grouting equipment

An intelligent and equipment technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as proportioning, extensive and irregular construction process, inaccurate control of water-to-binder ratio, and low reliability of grouting records. , to achieve the effect of improving the control level of the construction process, reducing the influence of human factors, and reducing the pollution of grouting dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

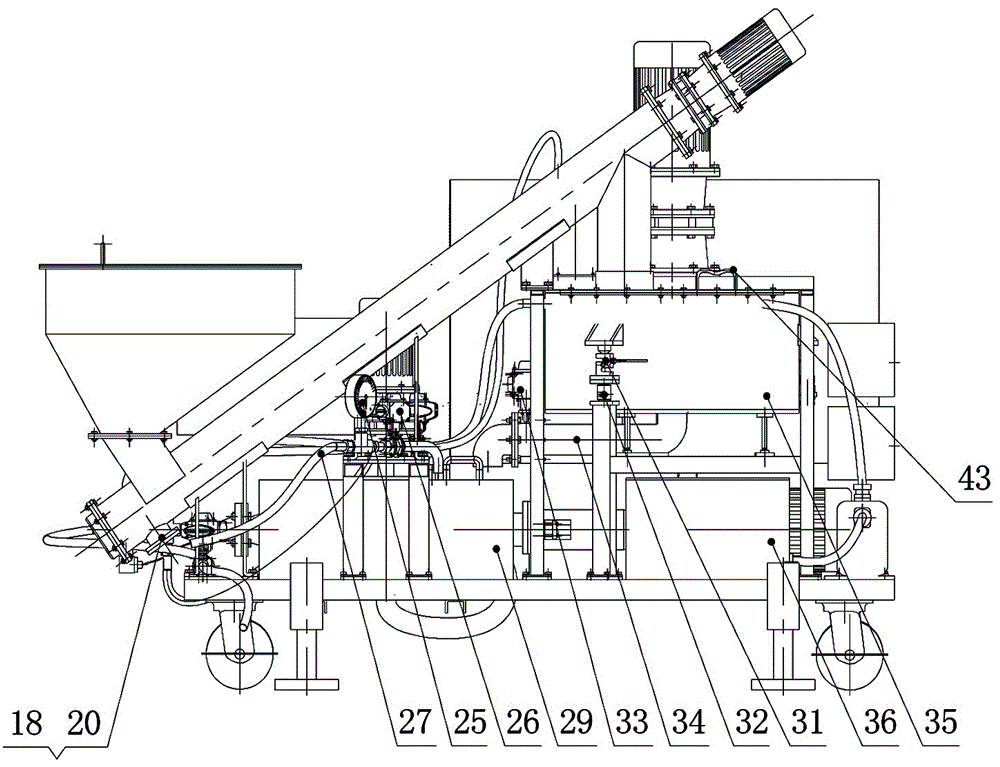

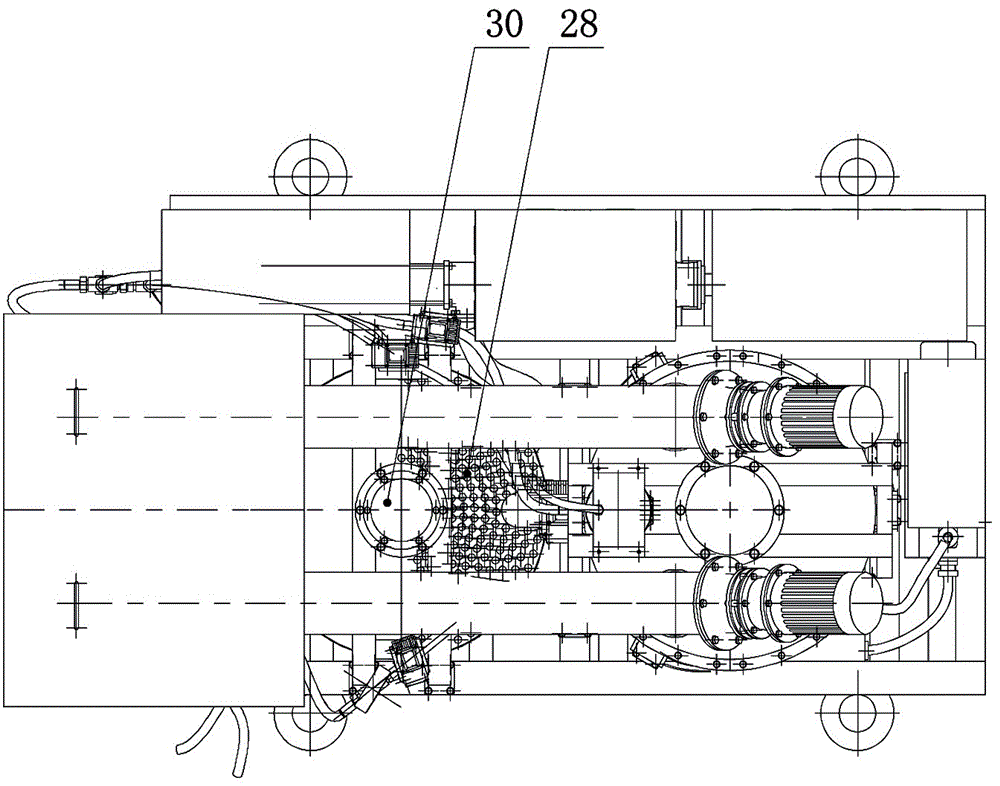

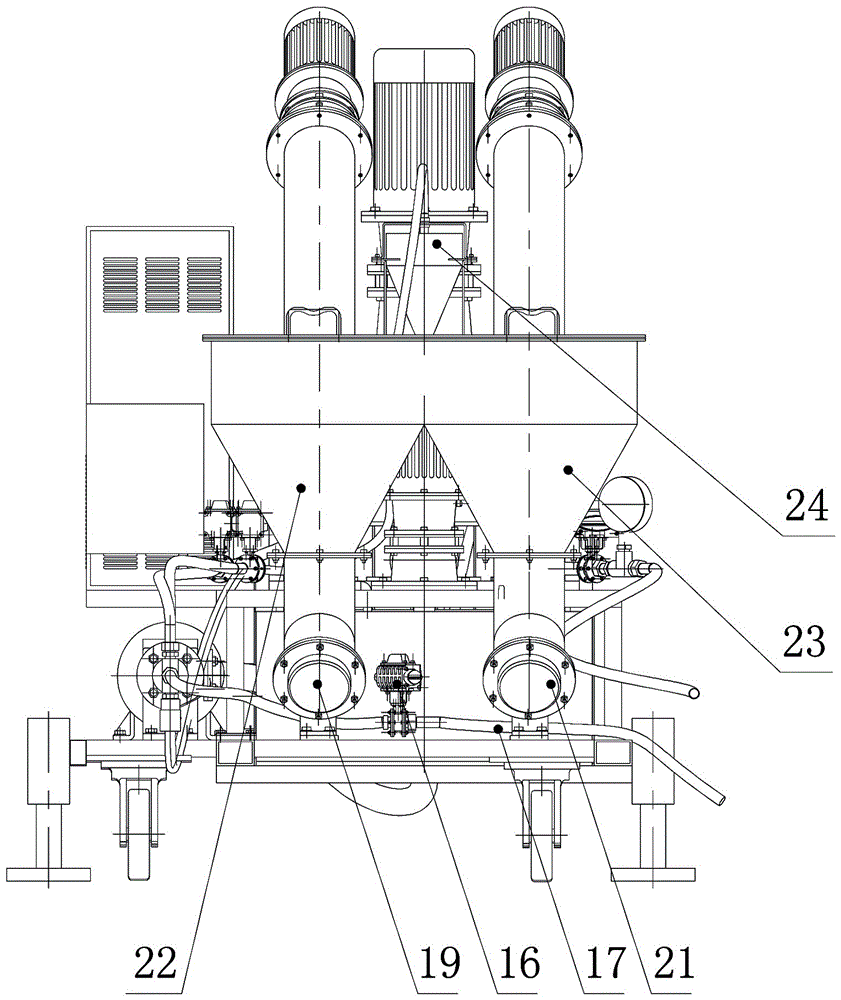

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 As shown, the intelligent large-scale grouting equipment includes automatic feeding system, automatic slurry fluidity detection system, weighing system, control center system, high-speed mixing system, low-speed mixing system, automatic grouting system, cleaning system, and power backup system . Automatic water adding system, the automatic feeding system includes cleaning outlet I 18, cement feeding pipe 19, cleaning outlet II 20, grouting agent feeding pipe 21, cement feeding trough 22, grouting agent feeding trough 23. The cement feeding tank 22 is connected to the lower part of the cement feeding pipe, and the cleaning outlet I is located below the cement feeding pipe; the grouting agent feeding tank 23 is connected to the lower part of the grouting agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com