Light-emitting diode and its manufacturing method

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as peeling off of phosphor powder layers, and achieve the effects of reducing investment in production equipment, increasing design freedom, and reducing process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

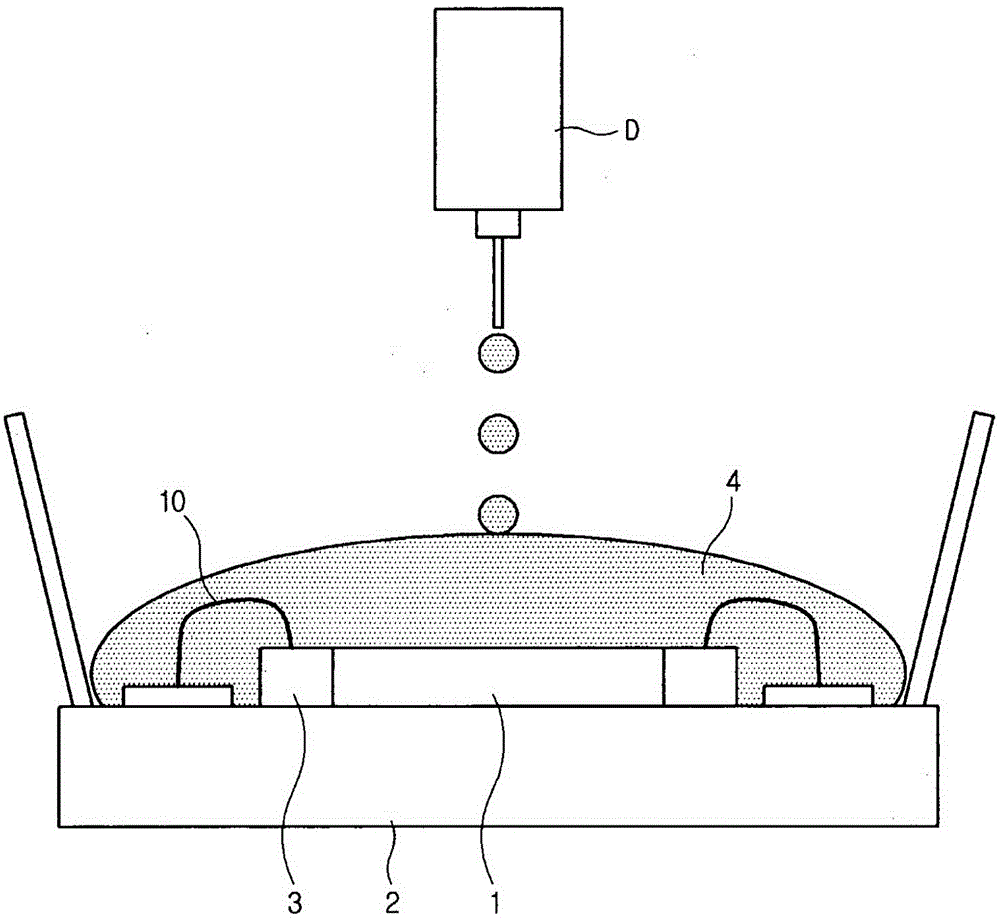

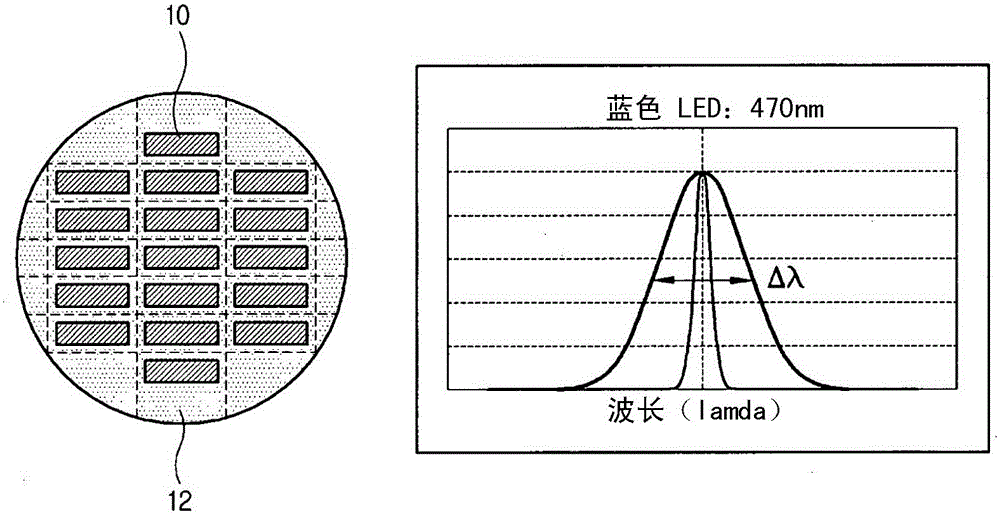

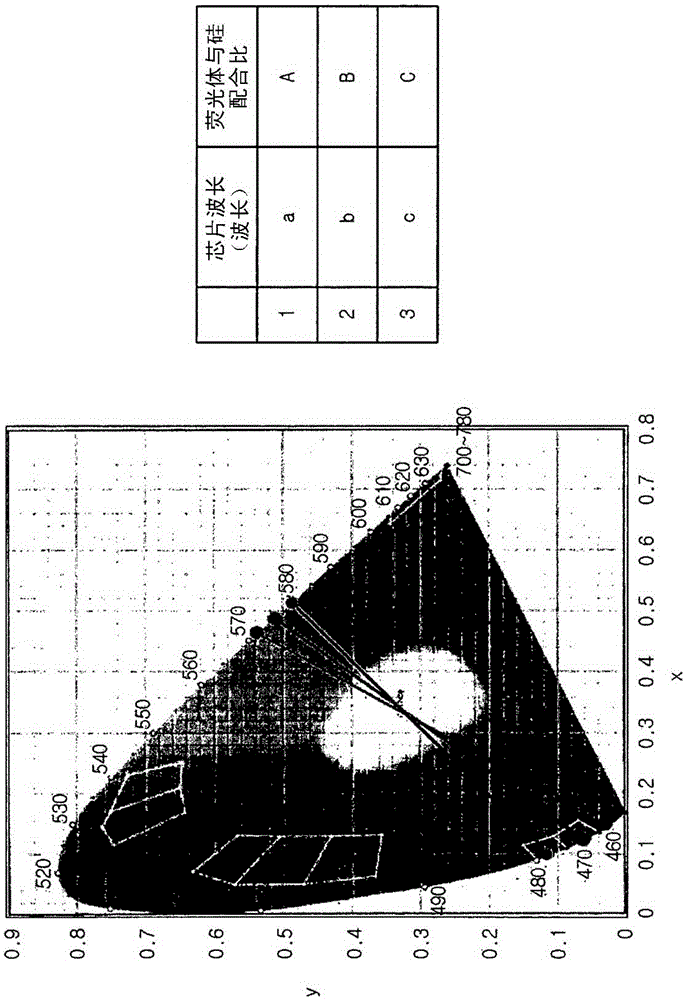

[0060] As described above, the present invention relates to a light emitting diode capable of outputting light of a desired wavelength by coating a phosphor / silicon complex layer and a method of manufacturing the same. In more detail, it is assumed that the wavelength of light emitted from a light emitting diode (LED) (assumed blue LED, ultraviolet LED) is measured at the wafer level. Based on the above wavelength measurement results, a conformal coating is applied to the above LED. The above-mentioned conformal coating has a phosphor compounding ratio based on the above-mentioned wavelength. In addition, the phosphor compounding ratio includes at least one of yellow, green, or red. Therefore, the light output from the above-mentioned LED is converted into white light using a conformal coating. In the embodiment of the present invention, these steps are performed at the wafer level, which can achieve better uniformity and inertia.

[0061] On the other hand, in the MOCVD (meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com