Magnetic treatment device and method for modification of hot pressing coring type iron-based diamond drill bit

A magnetic processing and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of high economic cost and easy pollution, and achieve low economic cost, wide application range, and reduce magnetic flux leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

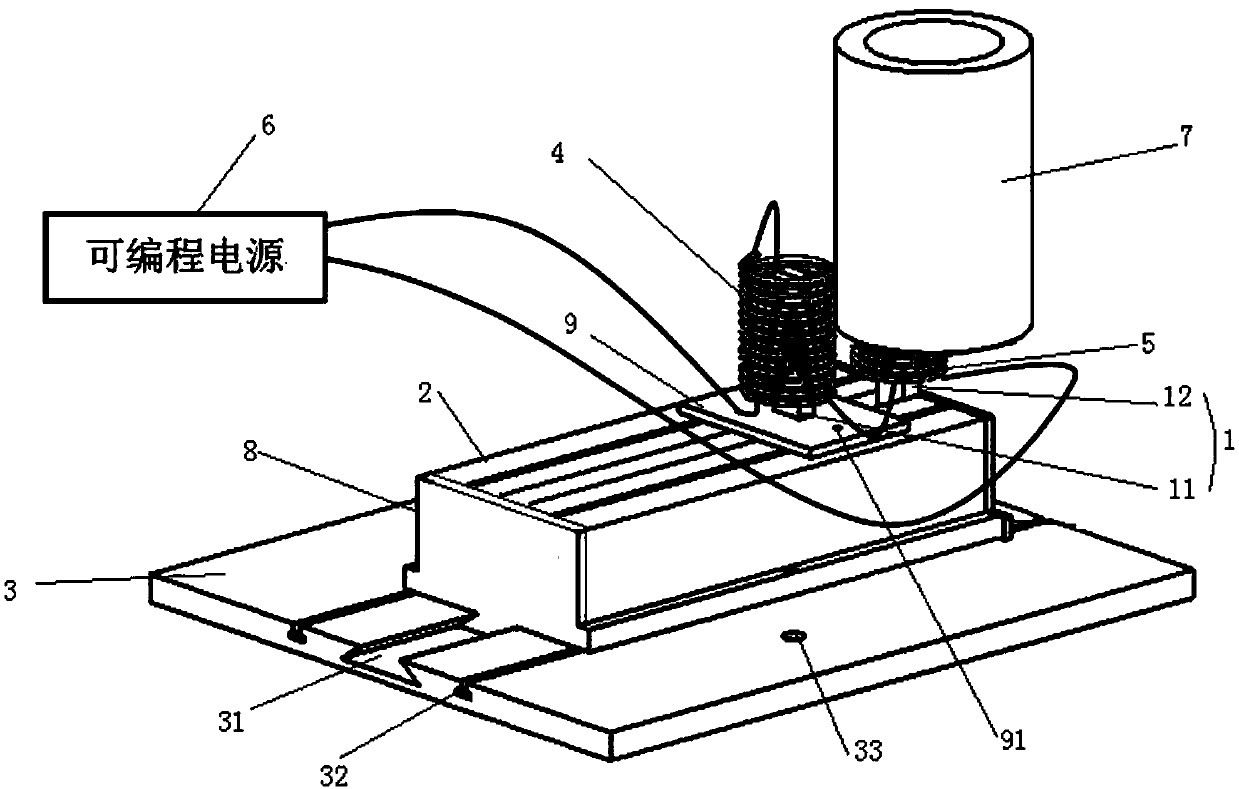

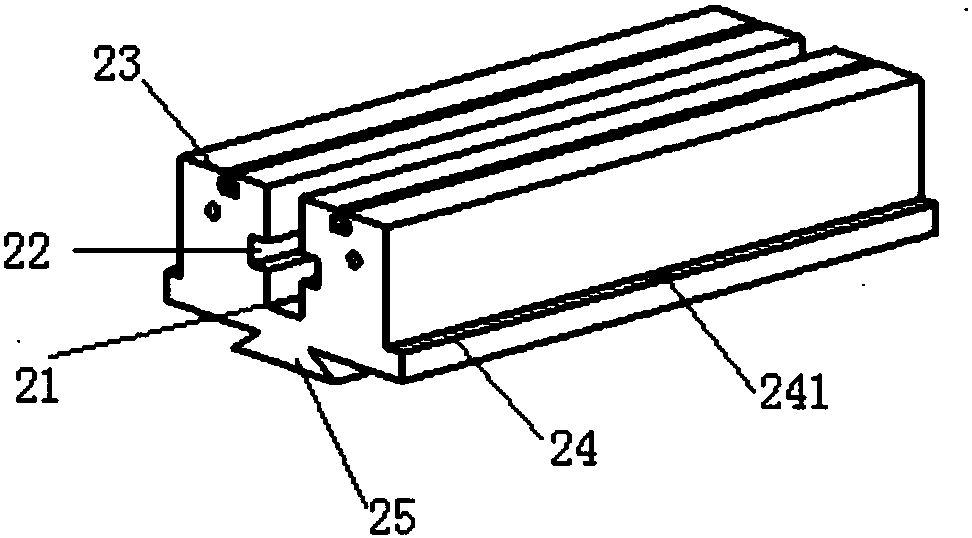

[0025] Please refer to figure 1 , the embodiment of the present invention provides a magnetic treatment device modified by a hot-pressed coring type iron-based diamond drill bit, the drill bit 7 is arranged above the magnetic treatment device, and the magnetic treatment device includes a U-shaped magnet 1, a sliding platform 2, a base plate 3. The first coil 4 , the second coil 5 and the programmable power supply 6 , the U-shaped magnet 1 is installed in the sliding platform 2 , and the sliding platform 2 is set on the bottom plate 3 and can slide along the bottom plate 3 .

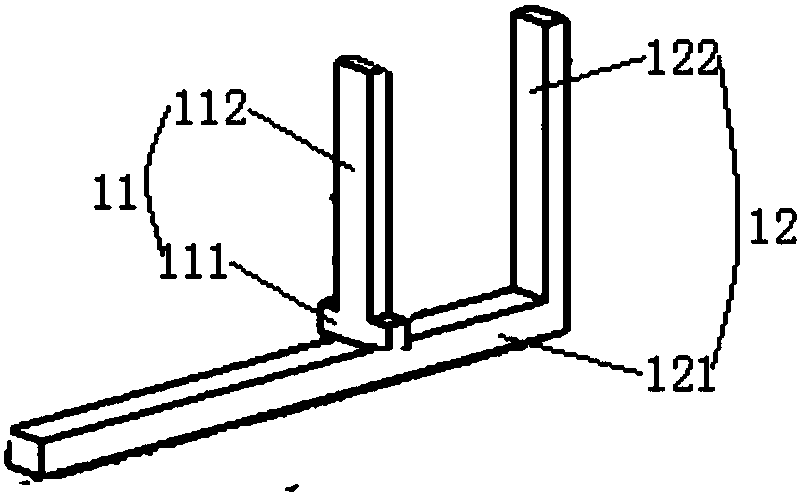

[0026] Please refer to image 3 , the U-shaped magnet 1 is made of an L-shaped iron core 12 and an inverted T-shaped iron core 11. In one embodiment, the L-shaped iron core 12 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com