A ring mode straw briquetting machine constant temperature device and its control method

A technology of straw briquetting machine and constant temperature device, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor straw molding stability, waste of resources, difficult molding temperature, etc., so as to shorten the heating time, improve the stability, and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

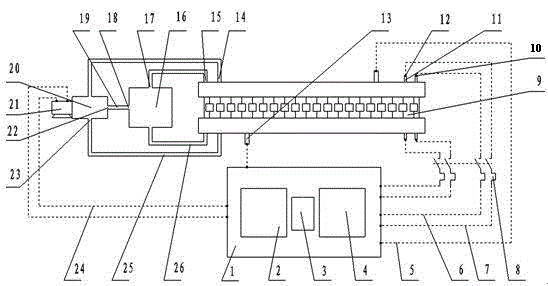

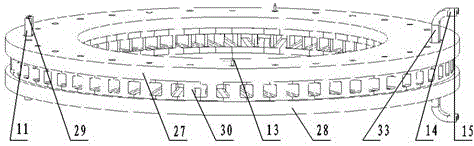

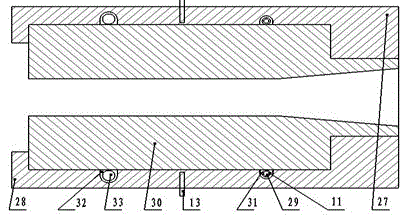

[0022] exist figure 1 Among them, the present invention is a constant temperature device for a ring mode straw briquetting machine, which includes a ring die 9, a water tank 16, a water pump 20, a control cabinet 1, a relay switch 8, a temperature sensor 13, a motor 21, a water pipe, an annular water pipe 33, Heating pipe 11, heating coil 29 and wires; water tank 16 is located on one side of ring die 9, water inlet 17 and water outlet 18 are respectively provided on water tank 16, and water inlet 17 of water tank communicates with water outlet 15 of annular water pipe through water pipe III26 , the water pump input port 22 communicates with the water tank outlet 18 through the water pipe I19, the water pump 20 output port communicates with the annular water pipe water inlet 14 through the water pipe II25, and the motor 21 is connected to the water pump, and the motor is connected with the motor control terminal through the wire IV24. The control terminal 2 is set in the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com