Casting forming machine for skateboard wheel

A molding machine and skateboard technology, applied in the field of pouring and molding, can solve problems such as low efficiency, and achieve the effects of improving work efficiency, stable internal temperature, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

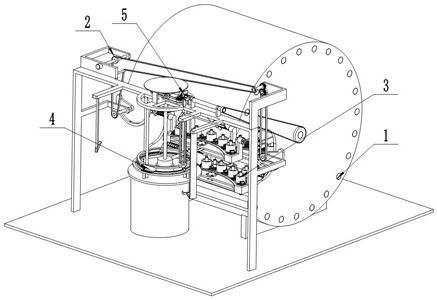

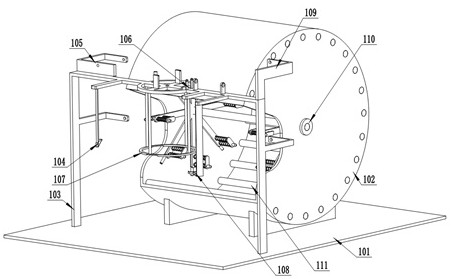

[0032] Example: Reference figure 1 The shown casting molding machine for a skateboard wheel includes a constant temperature component 1 for ensuring the molding temperature of the mold, a limit component 2 for limiting the position of the mold is arranged on the side of the constant temperature component 1, and eight groups for In the molding component 3 that places the mold and drives the mold to move in the constant temperature component, the constant temperature component 1 is provided with a demolding component 4 that automatically demolds the mold on the molding component, and the demolding component 4 is provided with a driving constant temperature component. Rotating molding assembly 3.

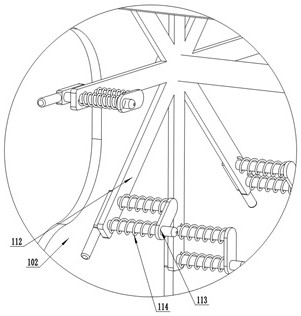

[0033] refer to figure 1 , figure 2 , image 3 and Figure 4As shown, the thermostatic assembly 1 includes a base 101, a support rod 103 and a thermostatic barrel 102 are arranged on the base 101, a rotating rod 112 and a plurality of groups of heating rods 111 are rotated inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com