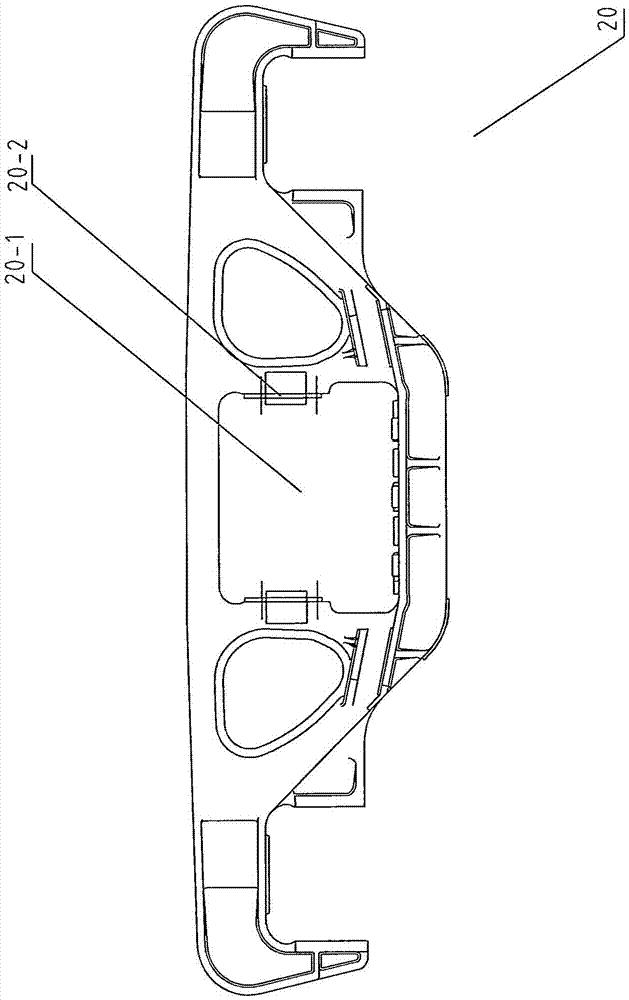

Four-spindle drilling machine for wearing plate on bogie side frame

A technology of wear plate and drilling machine, which is applied to the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., to ensure position accuracy and forming efficiency, improve maintenance and processing quality, and achieve multiple economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

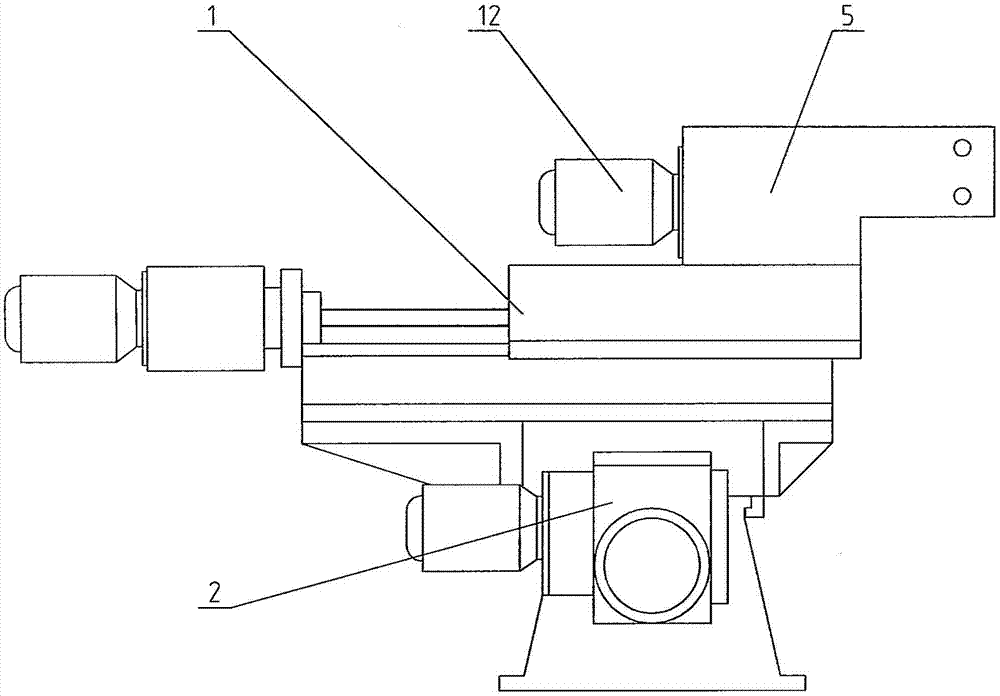

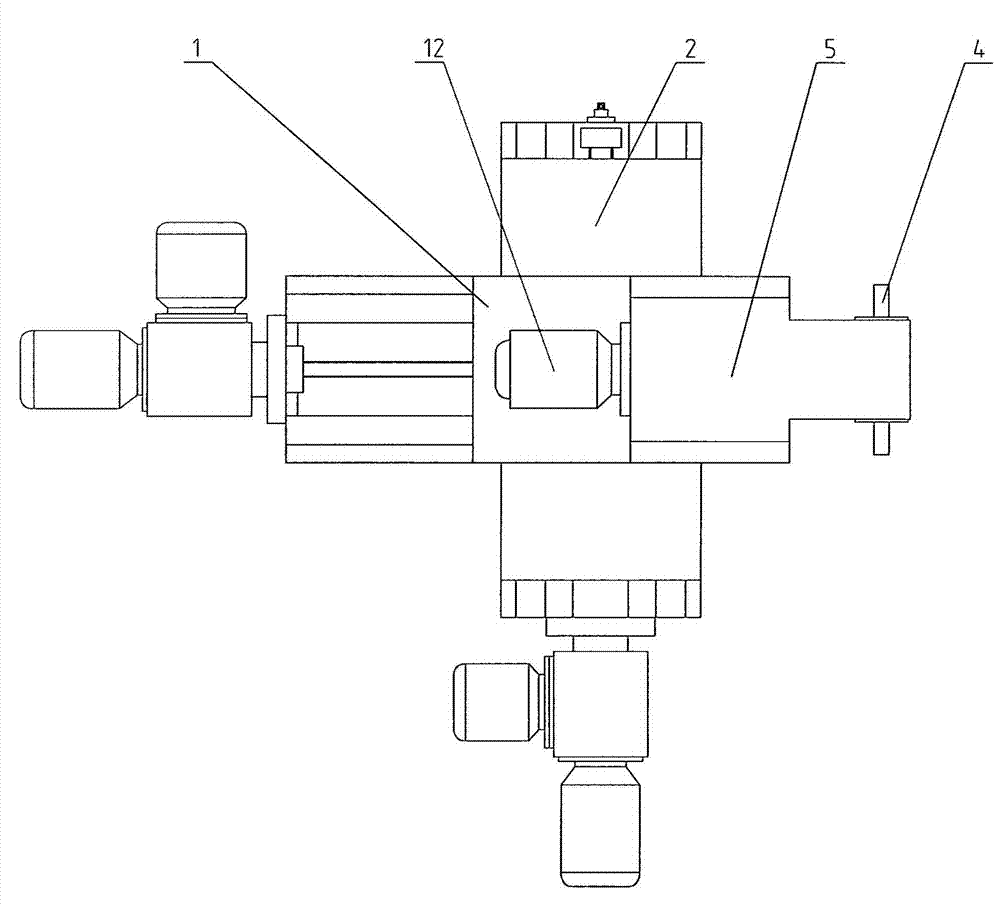

[0016] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

[0017] Such as Figure 2~6 As shown, a four-axis drilling machine for wear plates on bogie side frames, it includes a longitudinal mechanical slide 1, a transverse mechanical slide 2, four drilling power heads 3 and drives four drilling power heads 3 to rotate The power box, the power box can be vertically moved on the vertical mechanical slide 1, the longitudinal mechanical slide 1 can be installed on the horizontal mechanical slide 2, and the power box is equipped with two main shafts 4, each main shaft 4 A drilling power head 3 is respectively sleeved at both ends of the power box, and four drilling power heads 3 are symmetrically arranged on both sides of the power box. In this way, the present invention processes the installation holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com