Height-adjustable screw abutting seat component mechanism

An adjustable technology of anvil seat, applied in the field of medical devices, can solve the problems of complex parts processing, high requirements for parts processing accuracy, inconsistent staple forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

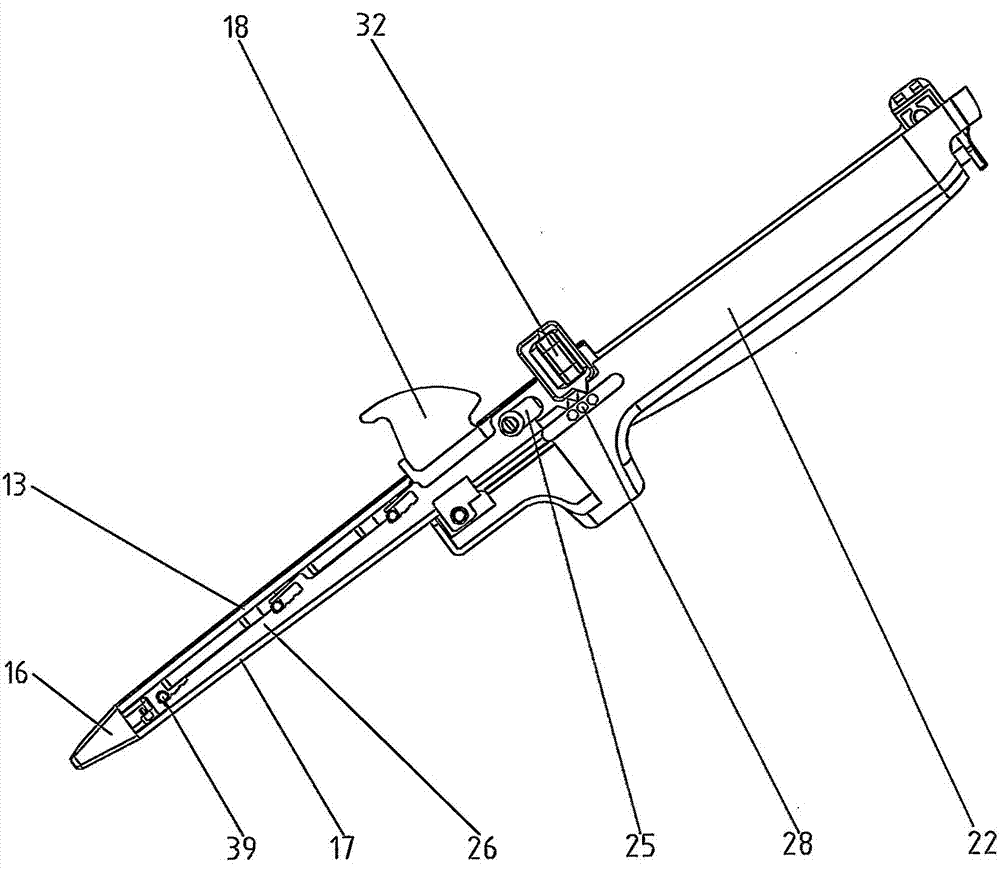

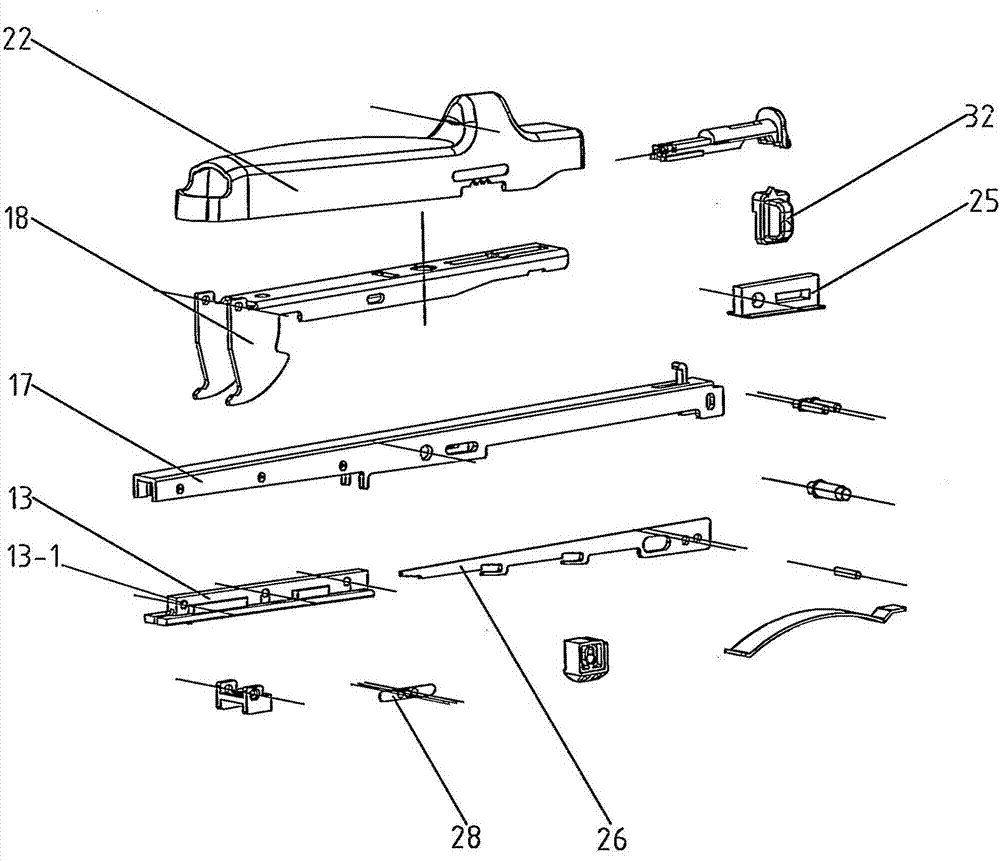

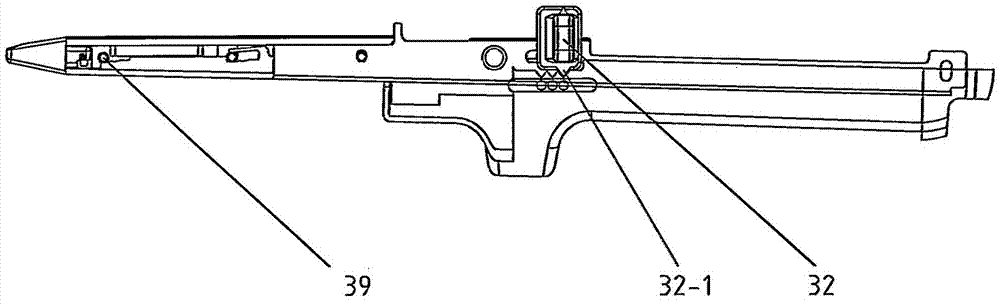

[0018] like Figure 1~8 As shown, a height-adjustable nail anvil assembly mechanism includes a nail anvil 13, a nail anvil frame 17 and a bulkhead 16. The nail anvil 13 is installed in the nail anvil frame 17, and the bulkhead 16 is installed in the nail anvil The head end of the frame 17 also includes spacers 25, adjustment pieces 26, pushers 32 and a plurality of guide pins 39, the spacers 25 and the adjustment pieces 26 are installed in the anti-nail frame 17, and the pushers 32 are movably installed On the spacer 25, the tail of the adjusting piece 26 is fixedly connected with the push-knob 32, and a plurality of pin holes 13-1 are opened on the nail-resistance seat 13, and the positions corresponding to the pin-holes 13-1 on the nail-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com