Semiconductor lighting device

A lighting device and semiconductor technology, applied in lighting devices, lighting device parts, lighting device cooling/heating devices, etc., can solve problems such as returning to the factory for repair or discarding, unfavorable to market competition, and restricting consumer choice, etc. Achieve the effect of solving the problem of interchangeability and the stability of the semiconductor lighting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

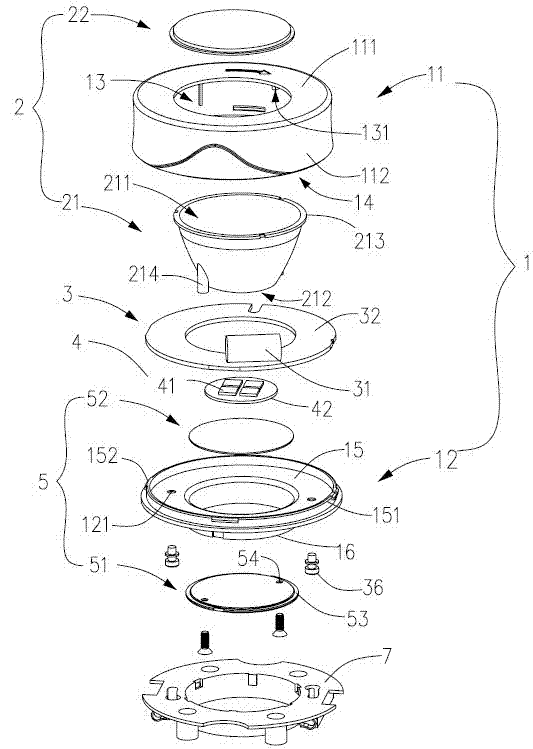

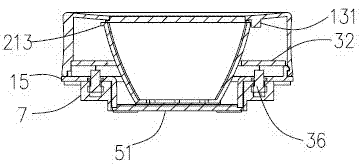

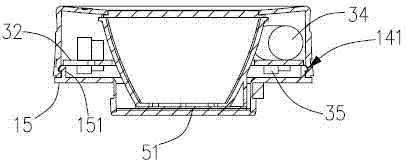

[0022] The semiconductor lighting device of the present invention will be further described in detail below in conjunction with specific embodiments and drawings.

[0023] Such as Figure 1 to Figure 4 As shown, in a preferred embodiment, the semiconductor lighting device of the present invention mainly includes a housing 1, an optical module 2, a driving electronic module 3, a light source module 4, and a heat treatment module 5. The casing 1 is open at both ends, and the shape can be roughly cylindrical, square column or triangular prism. The optical module 2, the driving electronic module 3, the light source module 4 and at least a part of the heat treatment module 5 are placed in the casing 1 to form a Integral lighting device.

[0024] In this embodiment, the housing 1 includes an upper housing 11 and a lower housing 12 that are detachably connected together. The upper housing 11 is cylindrical, and includes an upper end surface 111 in a ring shape and a side wall 112 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com