An automatic ice cream stick forming packing machine

An automatic forming and ice cream stick technology, which is applied in the directions of packaging and bundling machinery parts, etc., can solve the problems of low production efficiency, low degree of automation and large area of ice cream sticks, and achieves good packaging and bundling effect and high degree of automation. , the effect of high rotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

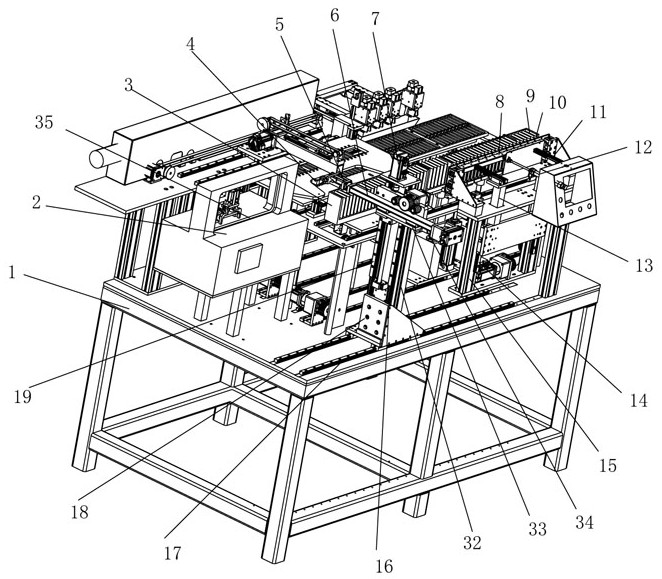

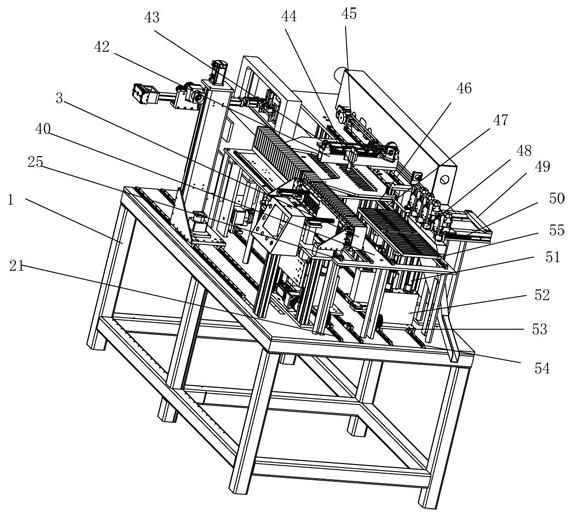

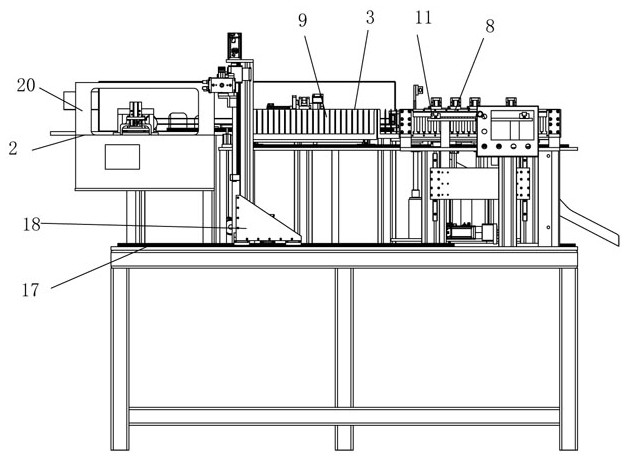

[0024] like figure 1 and 2 As shown in 3 and 4, an ice cream stick automatic forming and packing machine includes a frame 1, a support frame 40 is installed on the table surface of the frame, and a first upper guide rail 47 and a first upper guide rail 47 are installed on the rear side of the support frame 40. Lower rail 54 . The first upper rail 47 and the first lower rail 54 are parallel to each other, and the distance between the two rails of the first upper rail 47 is greater than the distance between the two rails of the first lower rail 54 . An upper bracket 56 is fitted on the first upper guide rail 47 , and an upper discharge tray 46 is fixed on the upper bracket 56 . A lower bracket 53 is fitted on the first lower guide rail 54, a first cylinder 52 is installed on the lower bracket 53, the first cylinder shaft 51 is fixed with the lower discharge tray 55, and the expansion and contraction of the first cylinder shaft 51 drives the lower discharge tray 55 to move. li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com