Dual-material powder laying device of additive manufacturing laser forming device

A laser forming and additive manufacturing technology, applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve problems such as low forming efficiency, and achieve the effect of ensuring forming efficiency, compact and reasonable structure, and space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

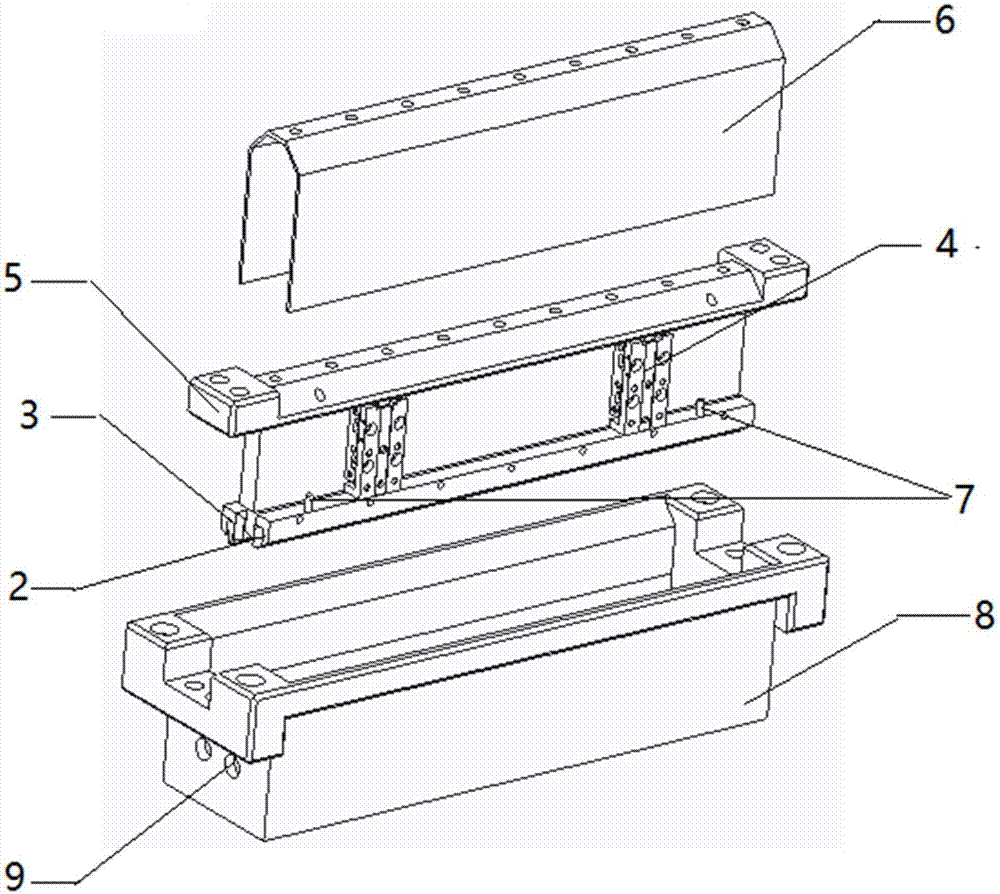

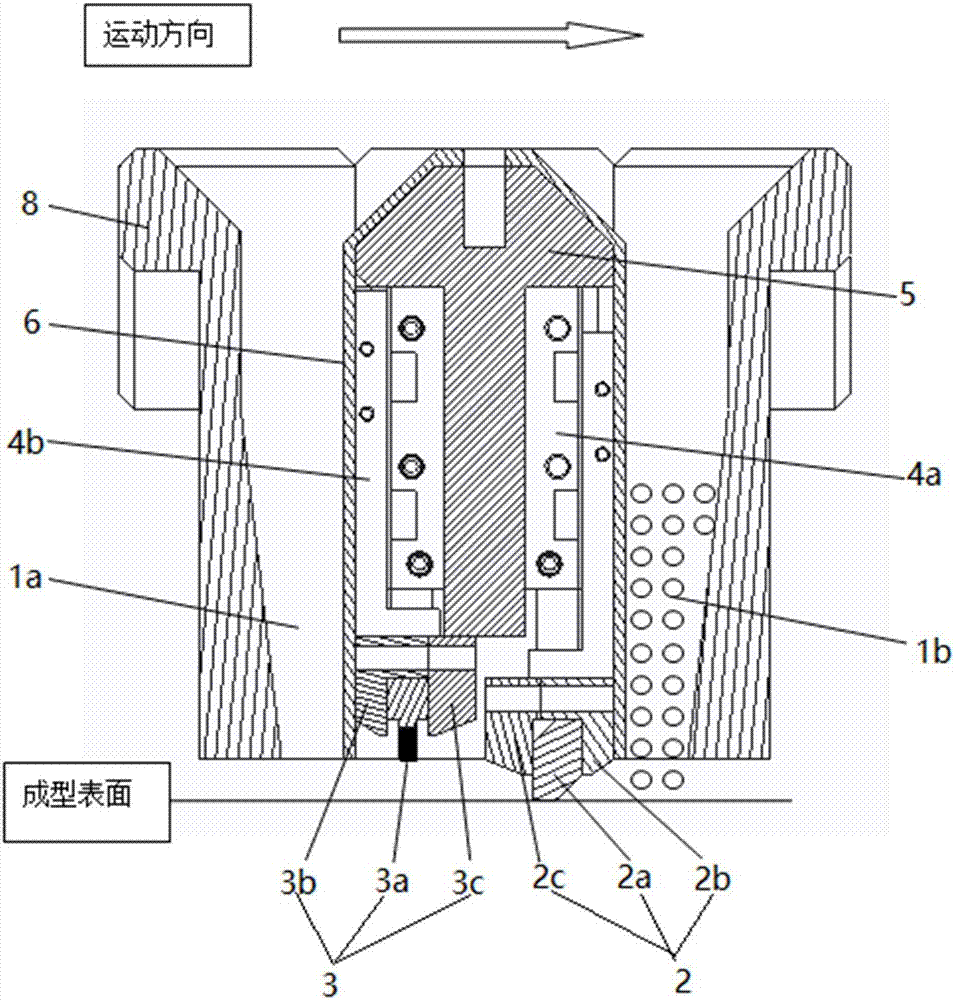

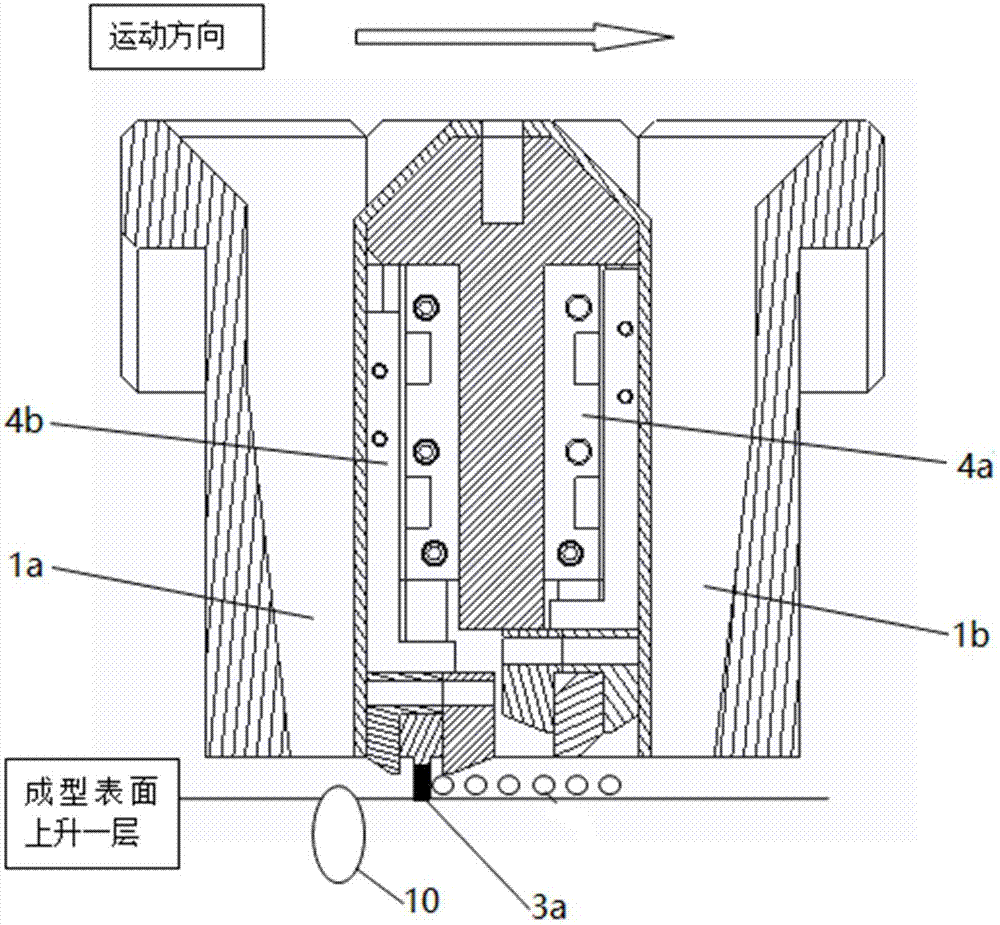

[0039] The dual-material powder spreading device of the additive manufacturing laser molding equipment of this embodiment, such as Figure 1-3 shown, including:

[0040] A powder falling part, the powder falling part is composed of a first powder falling part 1a and a second powder falling part 1b, used for storing and / or dropping different / identical powders;

[0041] The scraper assembly 2, the scraper assembly 2 includes a scraper 2a; the scraper 2a is fixed on the scraper mounting frame 5;

[0042] A brush assembly 3, the brush assembly 3 includes a brush 3a; the extension direction of the brush 3a and the scraper 2b are parallel to each other;

[0043] A driving part, the driving part is fixed on the side wall of the scraper mounting frame 5, and is connected with the scraper assembly 2 and the brush assembly 3, and is used to control the relationship between the scraper 2a and the brush 3a move.

[0044]Wherein, the specific structure and specific installation position...

Embodiment 2

[0060] The additive manufacturing laser molding equipment of this embodiment includes the dual-material powder spreading device described in Embodiment 1, and at least includes a molding platform 12, a molding shaft 13 and a molding cavity 14 for driving the molding platform 12 to move .

[0061] As a preferred implementation of this embodiment, the additive manufacturing laser molding equipment further includes a first powder collection part 15a and a second powder collection part 15b for collecting excess powder during powder spreading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com