Pump body molding and cooling device for production of electromechanical equipment

A technology of electromechanical equipment and cooling devices, applied in quenching devices, heat treatment equipment, metal processing equipment, etc., can solve the problems of low cooling liquid temperature drop, high cooling liquid temperature, and low heat dissipation efficiency, so as to ensure the dissipation performance , increase the surface area, improve the cooling effect of cold air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

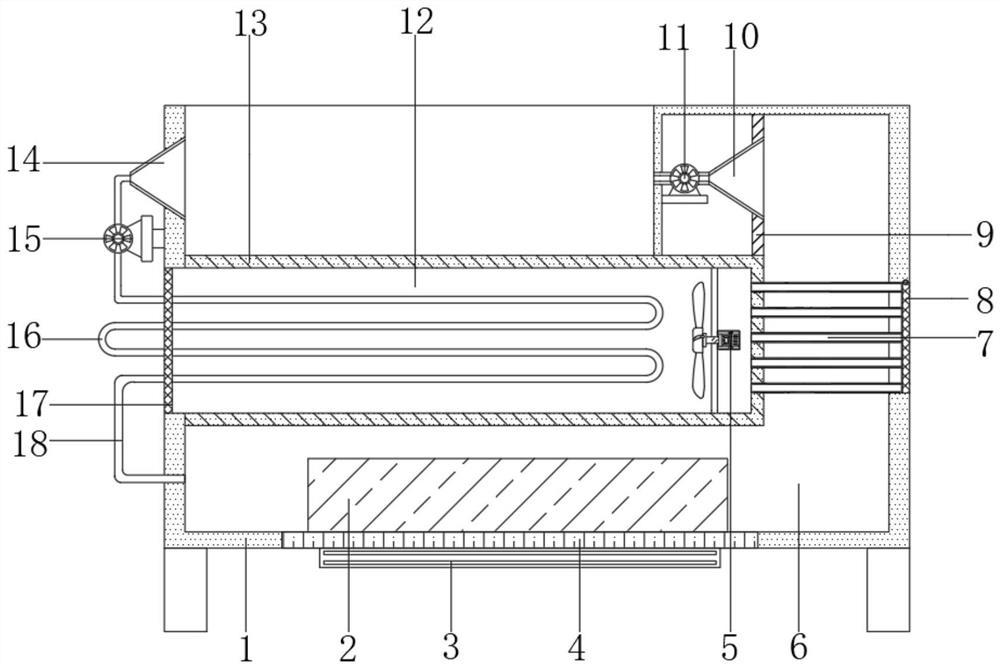

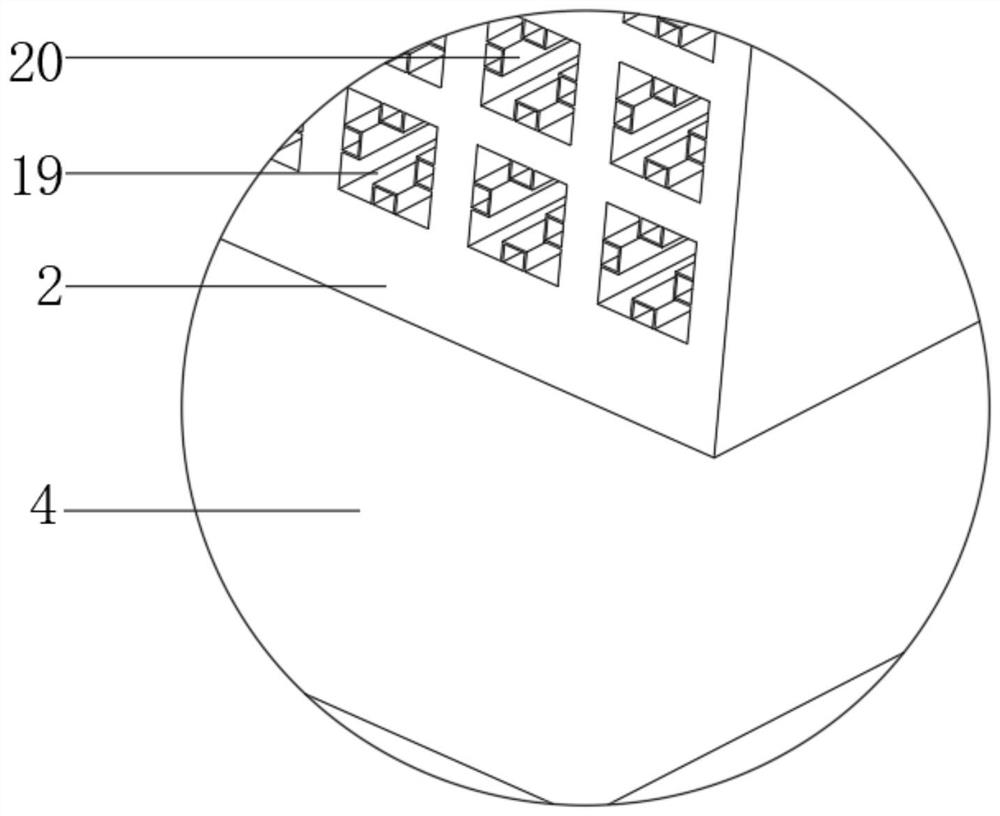

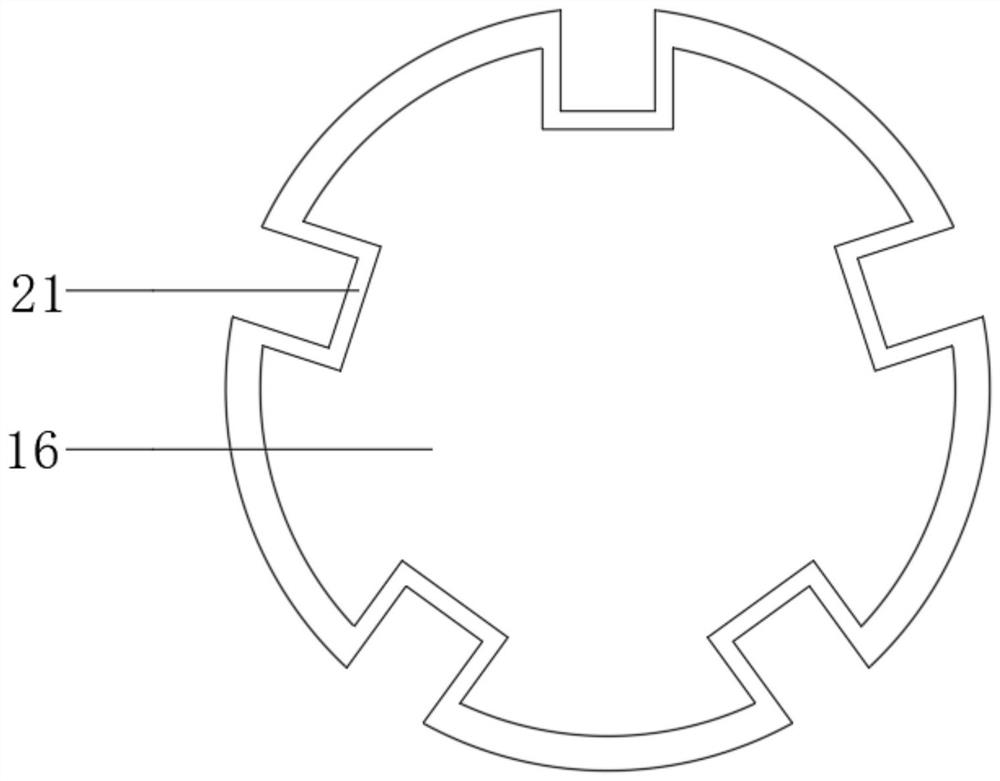

[0030] Reference Figure 1-4 , A pump body forming cooling device for the production of electromechanical equipment, comprising a main body 1 with legs welded on the four corners of the bottom outer wall, a U-shaped plate 13 is welded on one inner wall of the main body 1, and the main body 1 is open on the side close to the U-shaped plate 13 There is a heat dissipation port, the top of the main body 1 and the opposite side of the U-shaped plate 13 constitute a molding cavity, and the inner bottom of the main body 1 and the opposite side of the U-shaped plate 13 constitute a cooling end 6, and the bottom end of the cooling end 6 is provided with a mounting groove. And the inner wall of the installation groove is welded with a heat-conducting plate base 4, the bottom outer wall of the heat-conducting plate base 4 is fixed with a semiconductor refrigerator 3 by screws, and the top outer wall of the heat-conducting plate base 4 is welded with a heat exchange end 2, and the heat exch...

Embodiment 2

[0041] Reference Figure 5 , A pump body forming cooling device for the production of electromechanical equipment. Compared with the first embodiment, this embodiment also includes that one side outer wall of the rectangular branch pipe 20 is welded with a connecting piece 23, and the ends of the corresponding connecting piece 23 are welded with Two to three annular rings 22.

[0042] When the present invention is used, the arrangement of the connecting piece 23 and the annular ring 22 is used to further increase the contact heat exchange area between the heat exchange end 2 and the cooling liquid, thereby further improving the cooling effect of the cooling liquid and ensuring the cooling molding efficiency of the pump body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com