Automatic fiber placement forming method for grid skin structure with part concave structure

A technology of automatic wire laying and forming method, which is applied in the field of automatic wire laying and forming, and can solve the problems of inability to automatically lay wires and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

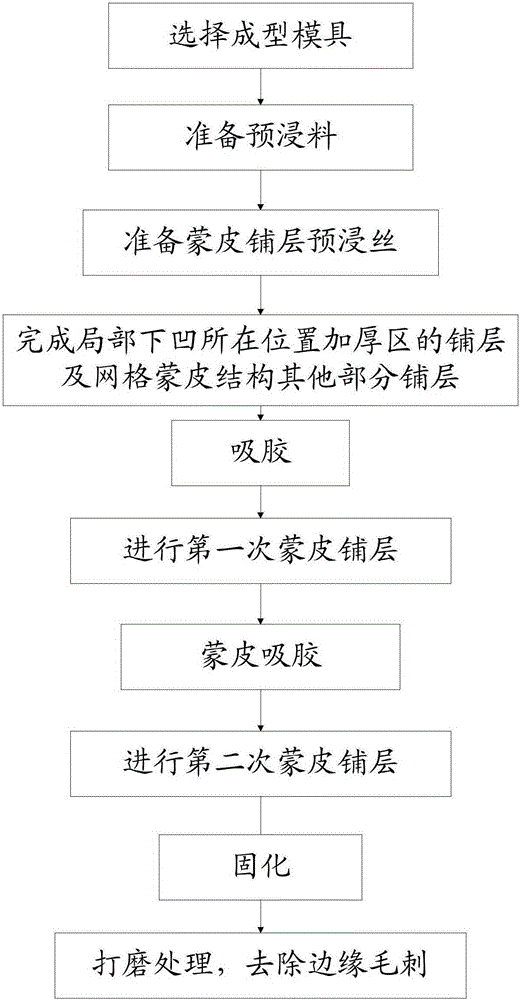

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Forming of a grid-skinned structure with vertical end frames

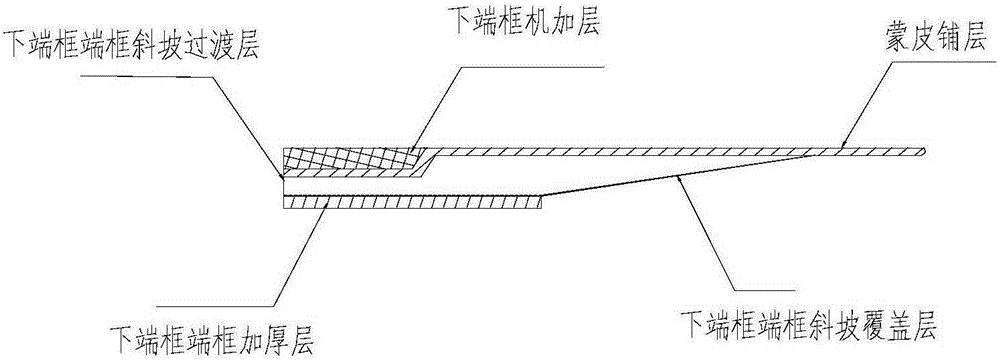

[0057] Vertical end frame forming requirements: The lower end frame of the component is a vertical end frame structure. In order to keep the skin layup continuous, the layup plan is modified at the thinned part of the lower end frame, and the thickened layup of the end frame is deleted. The thickness is reduced from 18.5mm to 11.5mm along the R8 arc. Such as figure 2 Shown is a schematic diagram of the layup of the lower end frame skin, reinforcement areas and ribs.

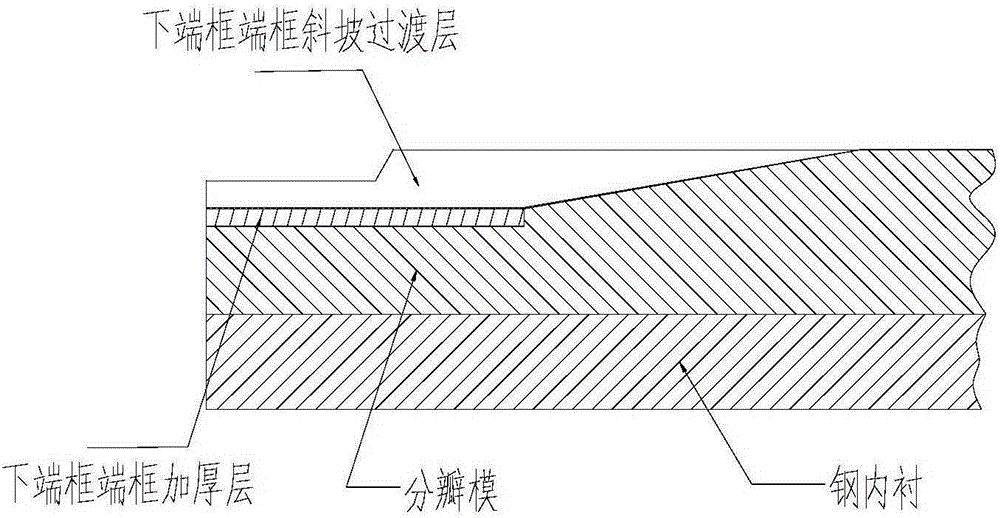

[0058] Due to the large thickness of the vertical end frame and the thickening area, it is necessary to lay the hot-melt prepreg into 5-7 layers of blocks first, enter the oven to pre-absorb the glue, and then carry out the block cutting and cutting according to the required size. Lamination, autoclave suction glue.

[0059] When the vertical end frame covers the suction glue, the upper and lower end rings need to be installed, a...

Embodiment 2

[0089] Embodiment 2: Forming of mesh skin structure with window

[0090] Window forming requirements: The window reinforcement area is formed directly instead of being processed after the product is cured. Its thickness is 20mm and is sharply reduced to 10mm at the edge of the window. The edge is different from the edge of the vertical end frame, and the edge of the laminate needs to be perpendicular to the skin. Such as Figure 8 Shown is a schematic diagram of the structure of the window reinforcement area.

[0091] (1) Forming mold preparation

[0092] Install the mold assembly, the process extension ring is not installed temporarily, clean the surface of the mold, and apply a release agent.

[0093] (2) Prepreg blanking

[0094] Prepreg by hot melt method. According to the three-dimensional digital model of the product, through conversion, the precise technology of the layer size in the window area is carried out, and the automatic blanking equipment is used for precis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com