Laying construction method and device for double-block type ballastless track sleeper

A ballastless track and construction equipment technology, which is applied in track, track laying, track maintenance, etc., can solve the problems of high total cost and long service life, achieve high precision installation equipment, facilitate transportation and installation, and ensure measurement and maintenance The effect of construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention is further illustrated with examples.

[0082] Construction method of the present invention comprises the following steps:

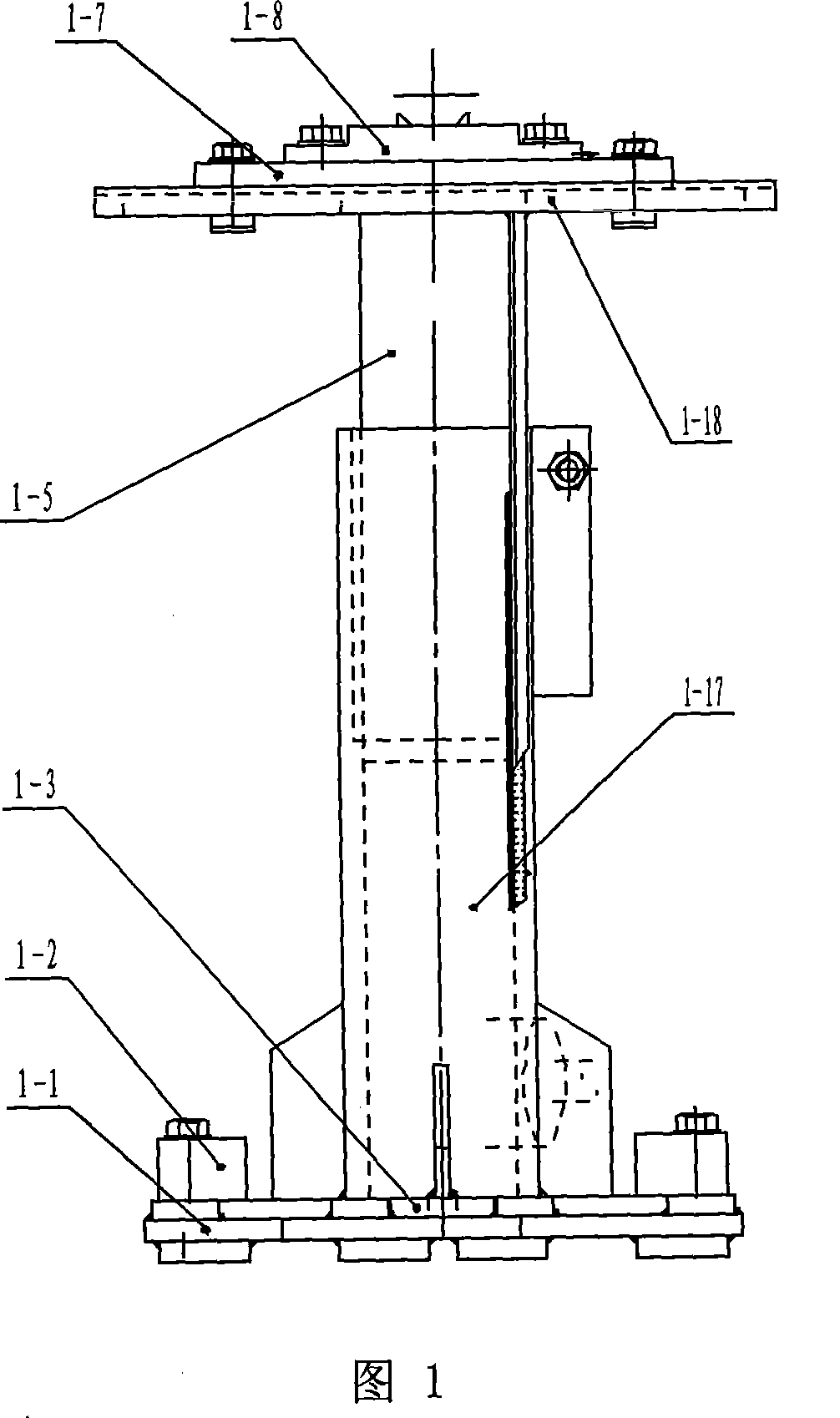

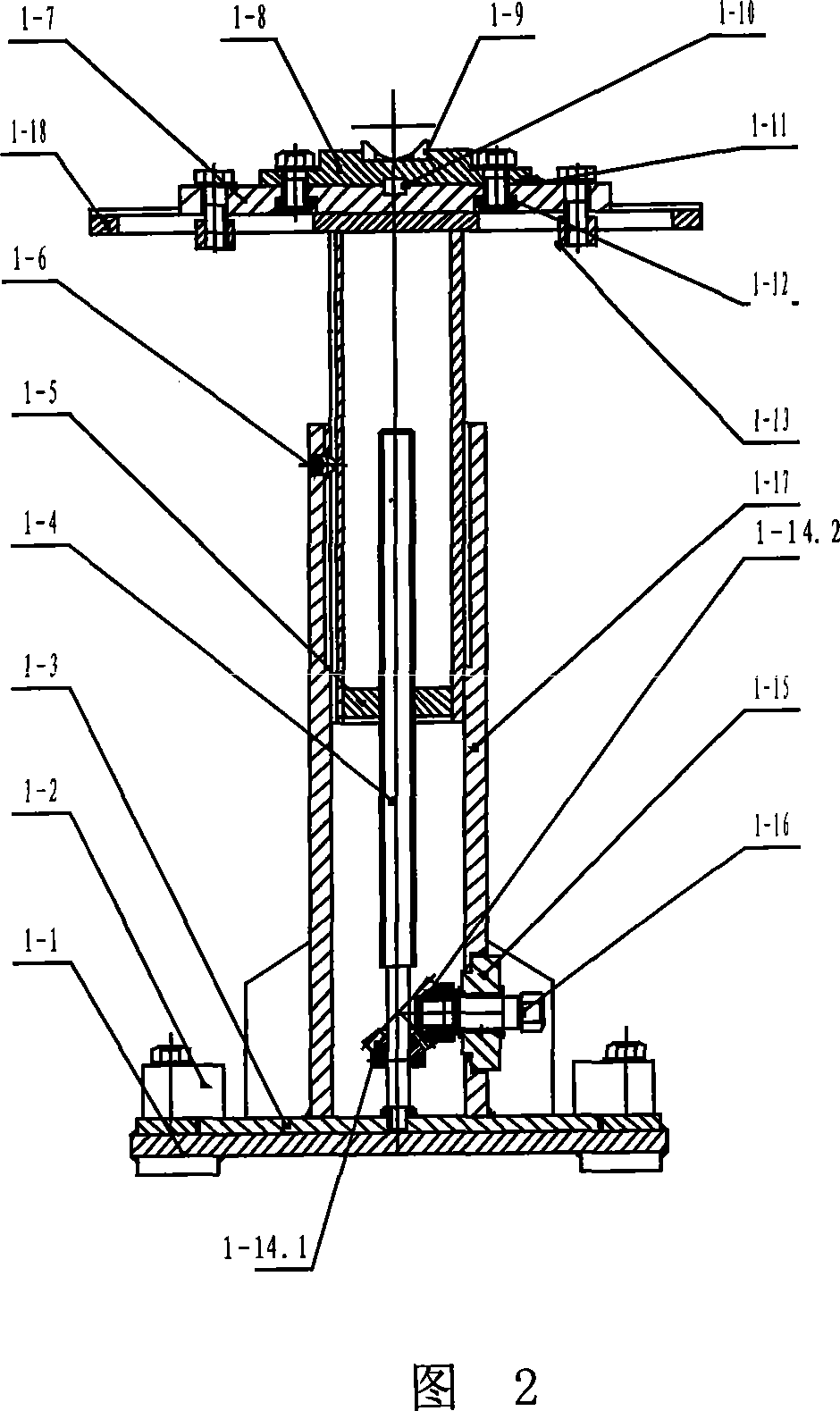

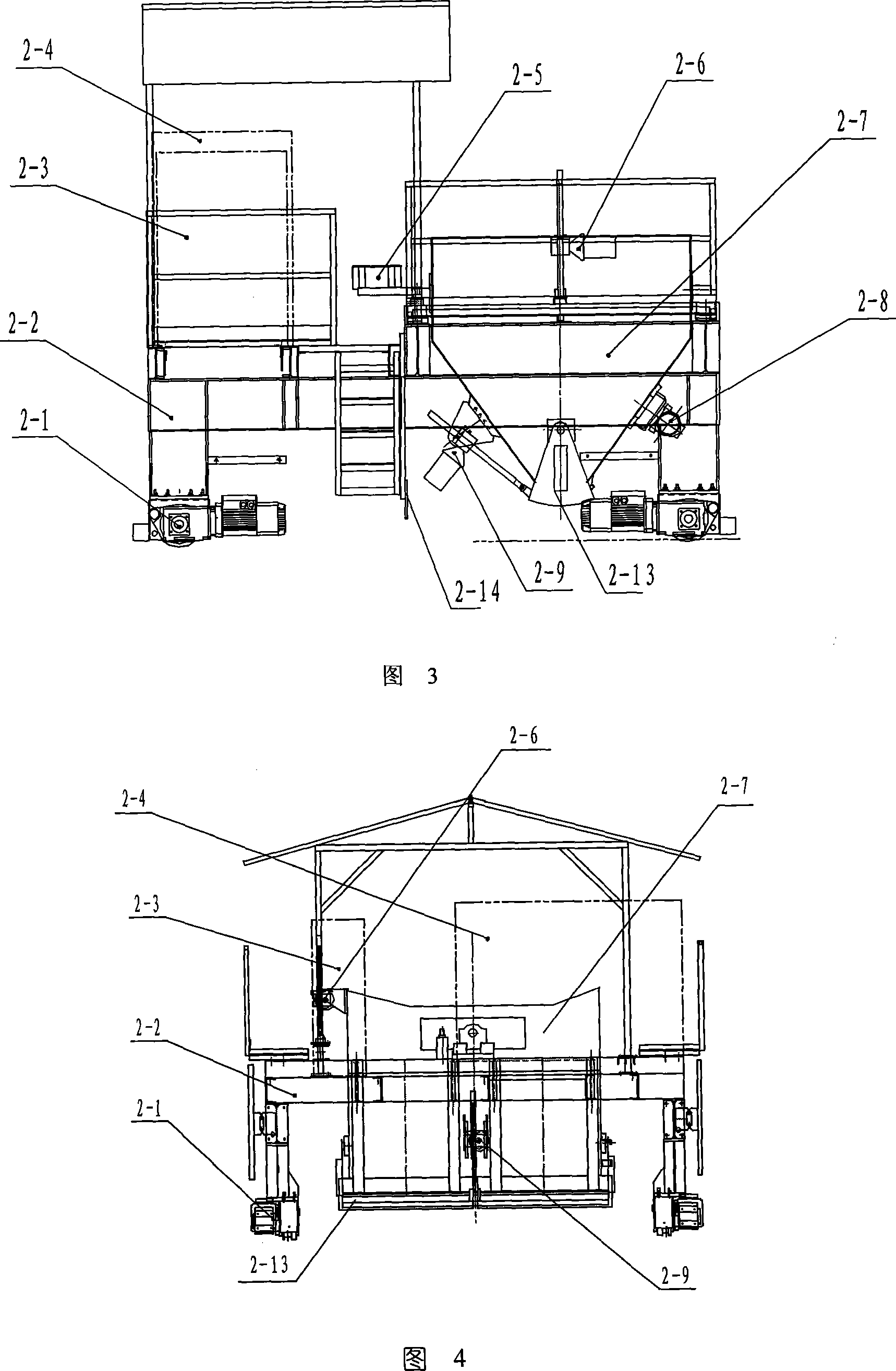

[0083] A concrete load-bearing layer is laid on the road base, and formwork for pouring the concrete of the ballast bed and tracks for each unit equipment are installed symmetrically on both sides of the concrete load-bearing layer; the track formwork is fixed on the load-bearing layer as the foundation by pins, each The formwork is 3250mm long and forms a 90° angle with the ground. When laying the sleepers at the bend, in order to raise the formwork on one side to a certain height, two underlay frames can be added under the formwork at most, and the underlay frames are connected with the lower bearing layer and the upper track formwork with bolts. The placement of the underlay frame will cause a certain height difference between the two sides of the track formwork, which will cause inconvenience to the exercise of each unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com