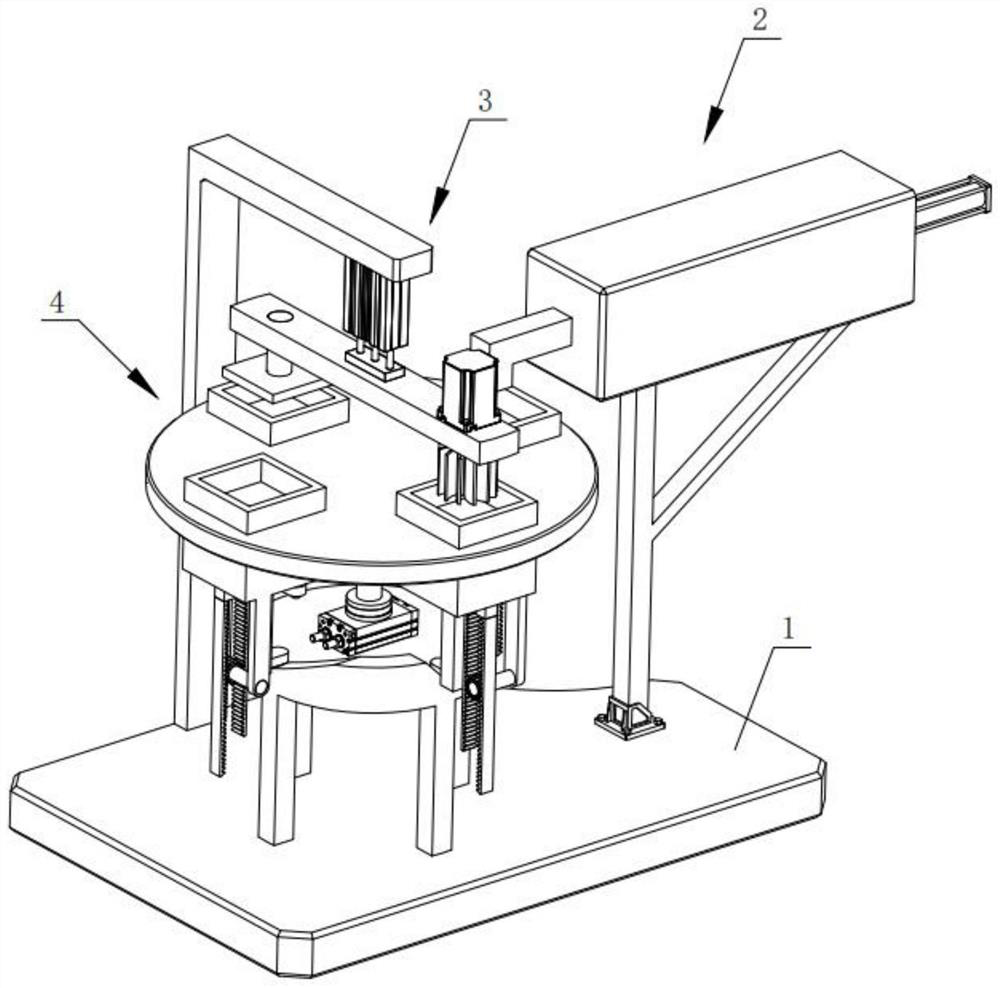

Dough sheet forming device for blackberry biscuit production

A blackberry biscuit and forming device technology, which is applied in the direction of dough forming machinery or equipment, application, dough processing, etc., can solve the problems of difficult removal of biscuit dough and low processing efficiency, so as to avoid manual operation and ensure the effect of forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

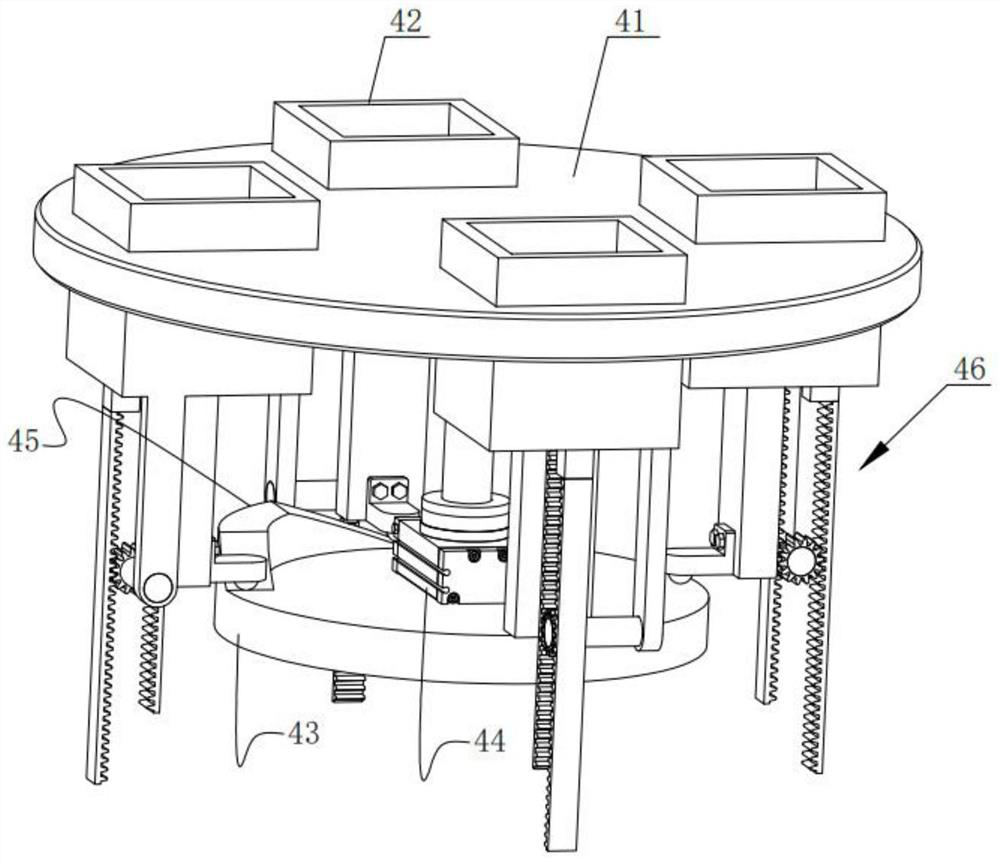

[0028] The multi-station forming assembly 4 includes a top plate 41, a forming bin 42, a disc 43, a rotating cylinder 44, a raised block 45 and a jacking group

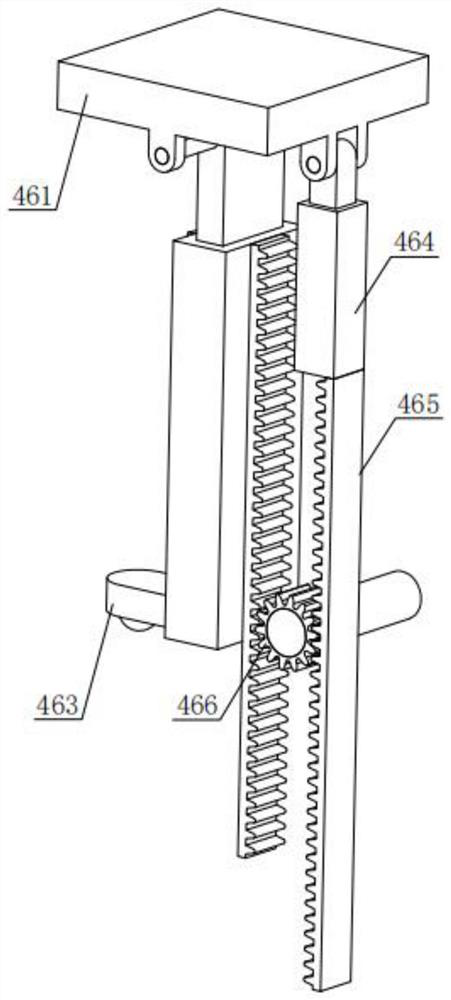

[0029] The forming chamber 42 is provided with a jacking assembly 46, and the jacking assembly 46 includes a piston plate 461, a telescopic rod assembly 462, a baffle plate

[0034] During the forming process, by adjusting the length of the inner rod 4622 extending out of the outer rod 4621, the piston plate 461 is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com