Sand mould casting process

A technology of sand casting and process, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor molding effect, low workpiece yield, and affecting molding efficiency, so as to increase the scope of application, reduce the content of sand and dust, Guarantees the effect of respiratory health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

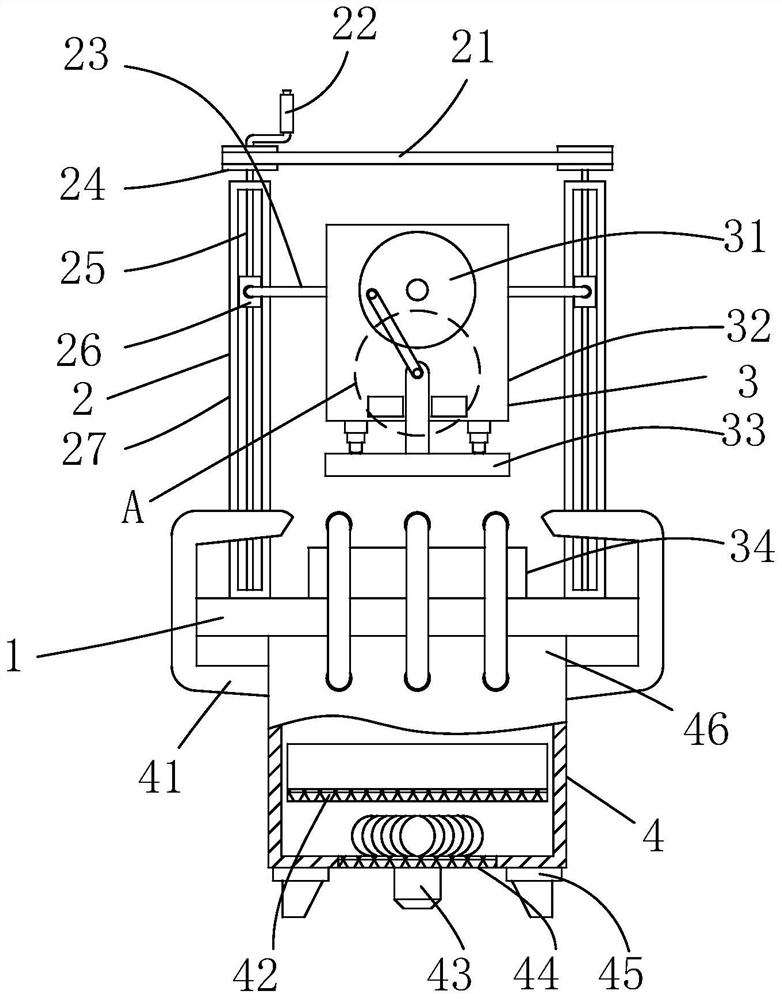

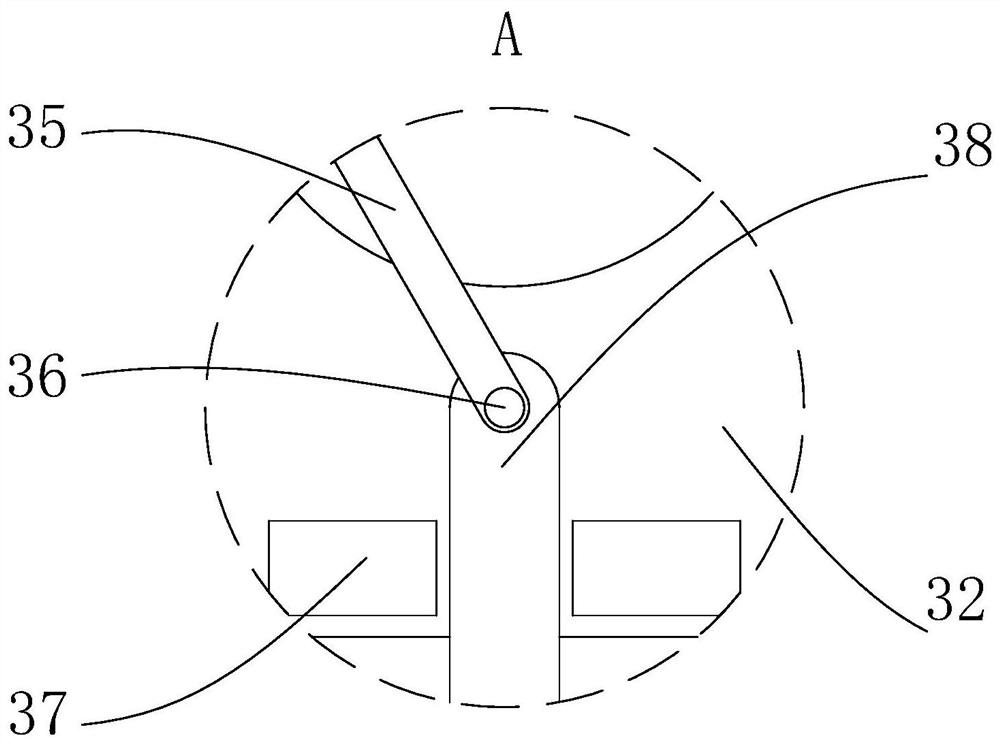

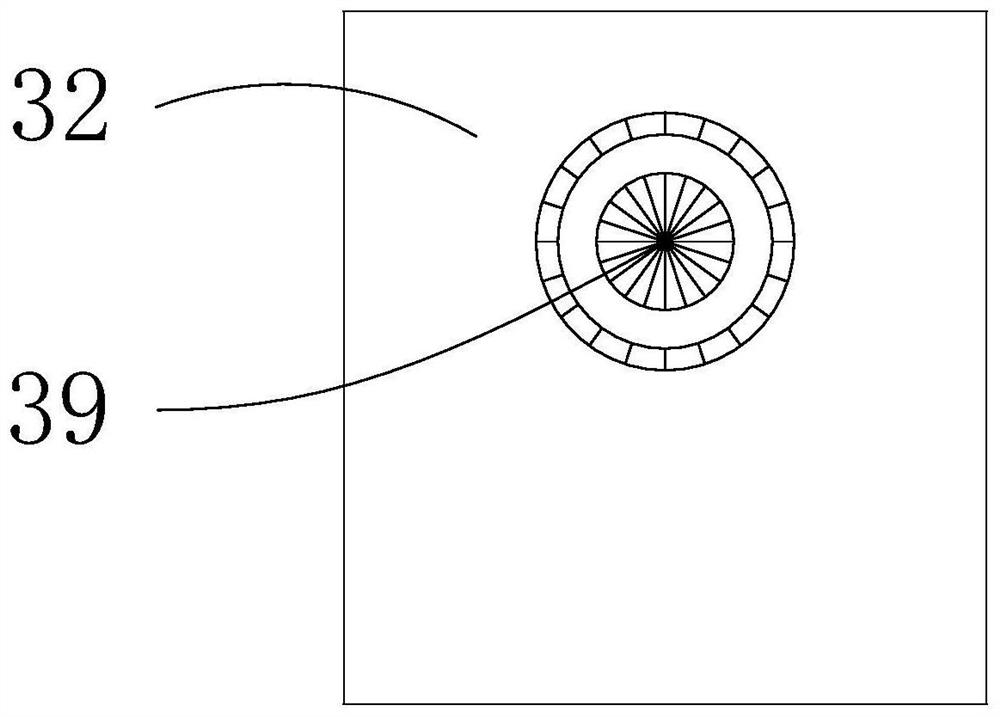

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , a sand casting process, comprising the following steps:

[0027] S1: Prepare the green sand mold; screen the prepared model sand with a fineness modulus of 2.2-1.6 using a 45-mesh sieve, and then use the green sand box molding machine to prepare the model sand that has been screened. Qualified wet sand molds for casting;

[0028] S2: Put the prepared raw materials into the furnace according to the proportion of the formula, and melt them at high temperature to fully mix the raw materials. The temperature of the molten liquid is 1400-1600 ° C, and the melting time is 4-5 hours. Stir once every 30 minutes to ensure sufficient mixing;

[0029] S3: Preheat the wet sand mold prepared in step S1, the preheating temperature is 400-600°C, and the preheating time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com