Bottle preform loading device

A preform and preform separation technology, which is applied in the field of linear blow molding machine preform separation equipment, can solve the problems of only suitable for uniform pitch, low efficiency of preform loading, low safety factor, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

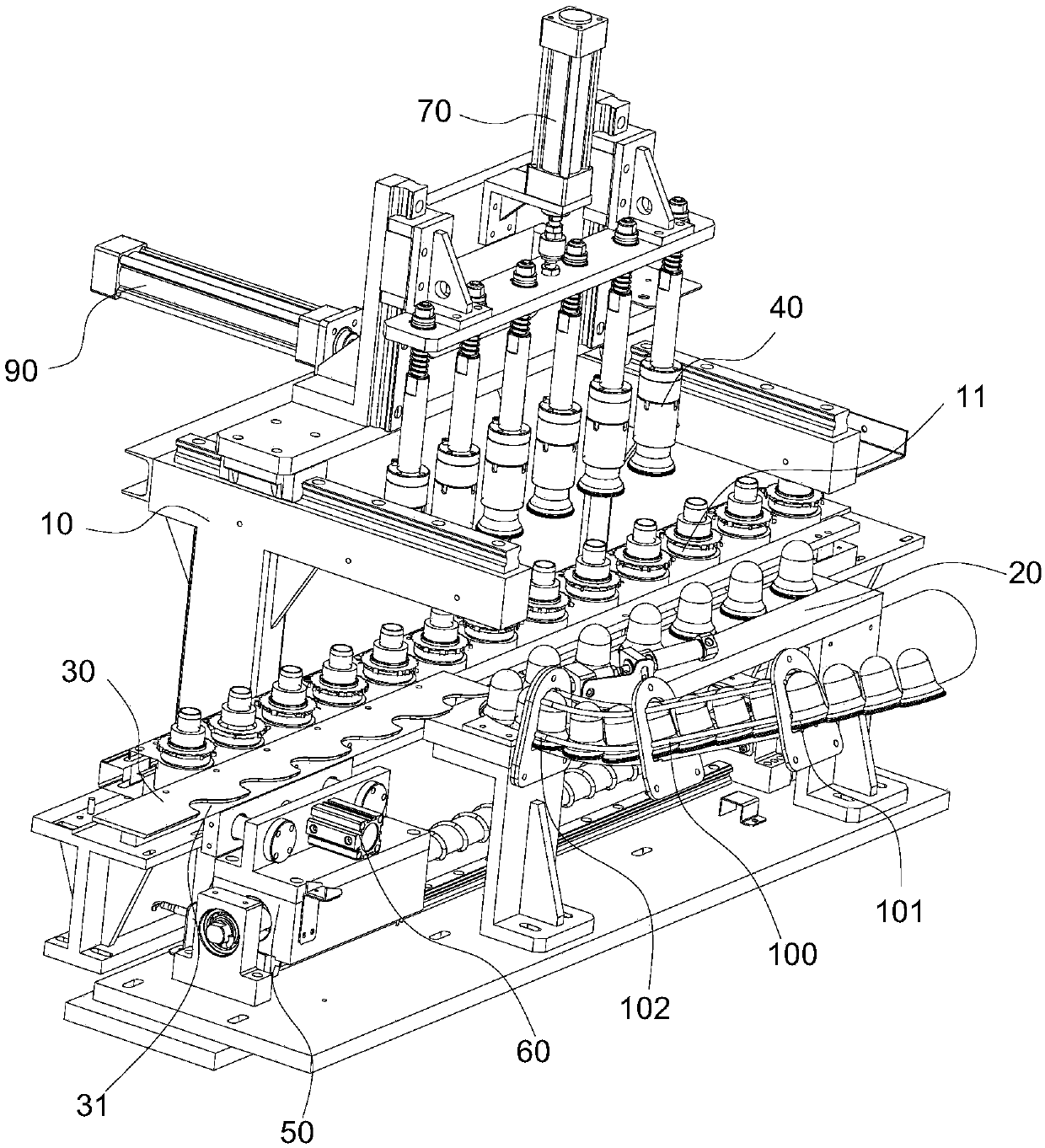

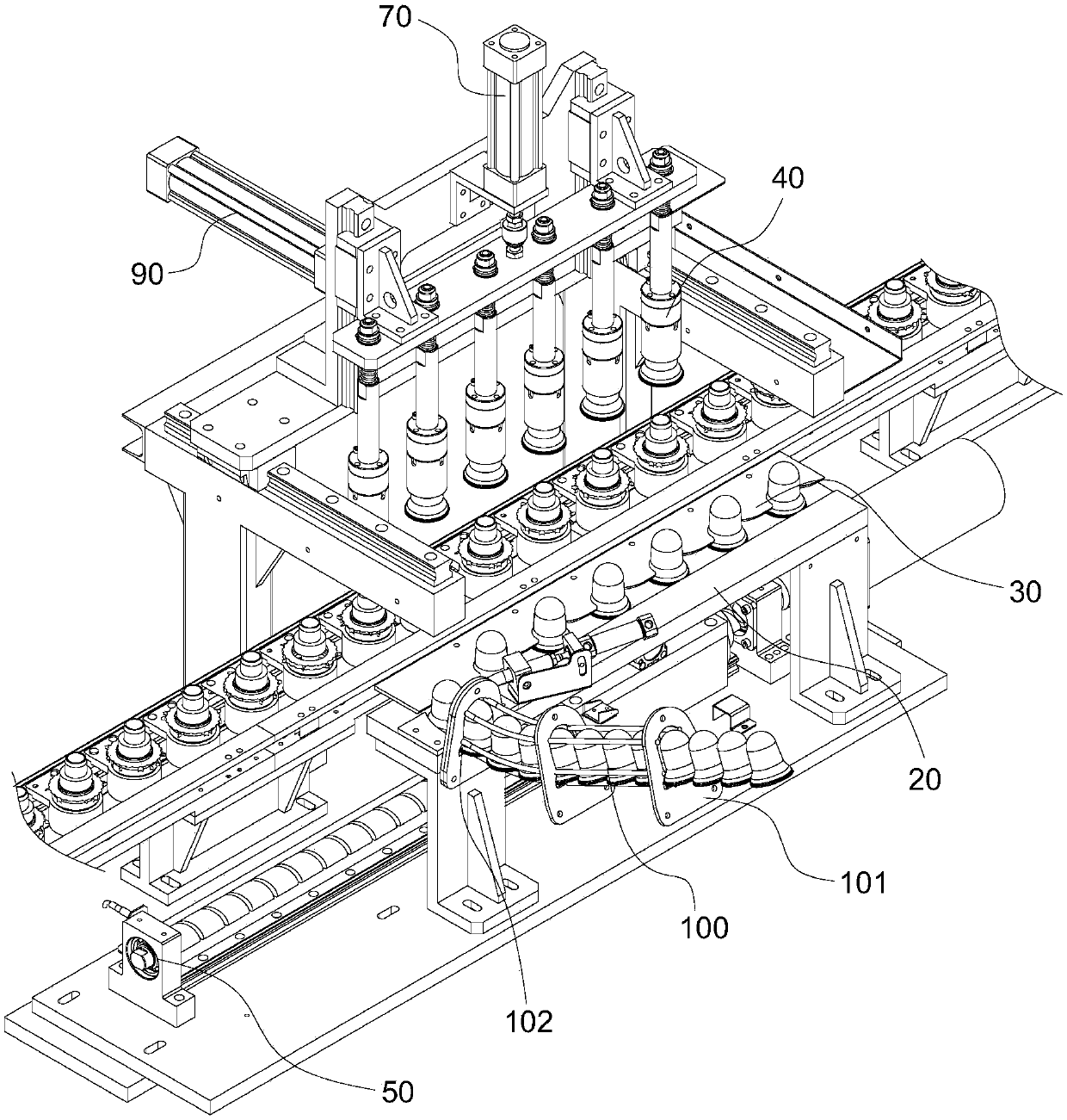

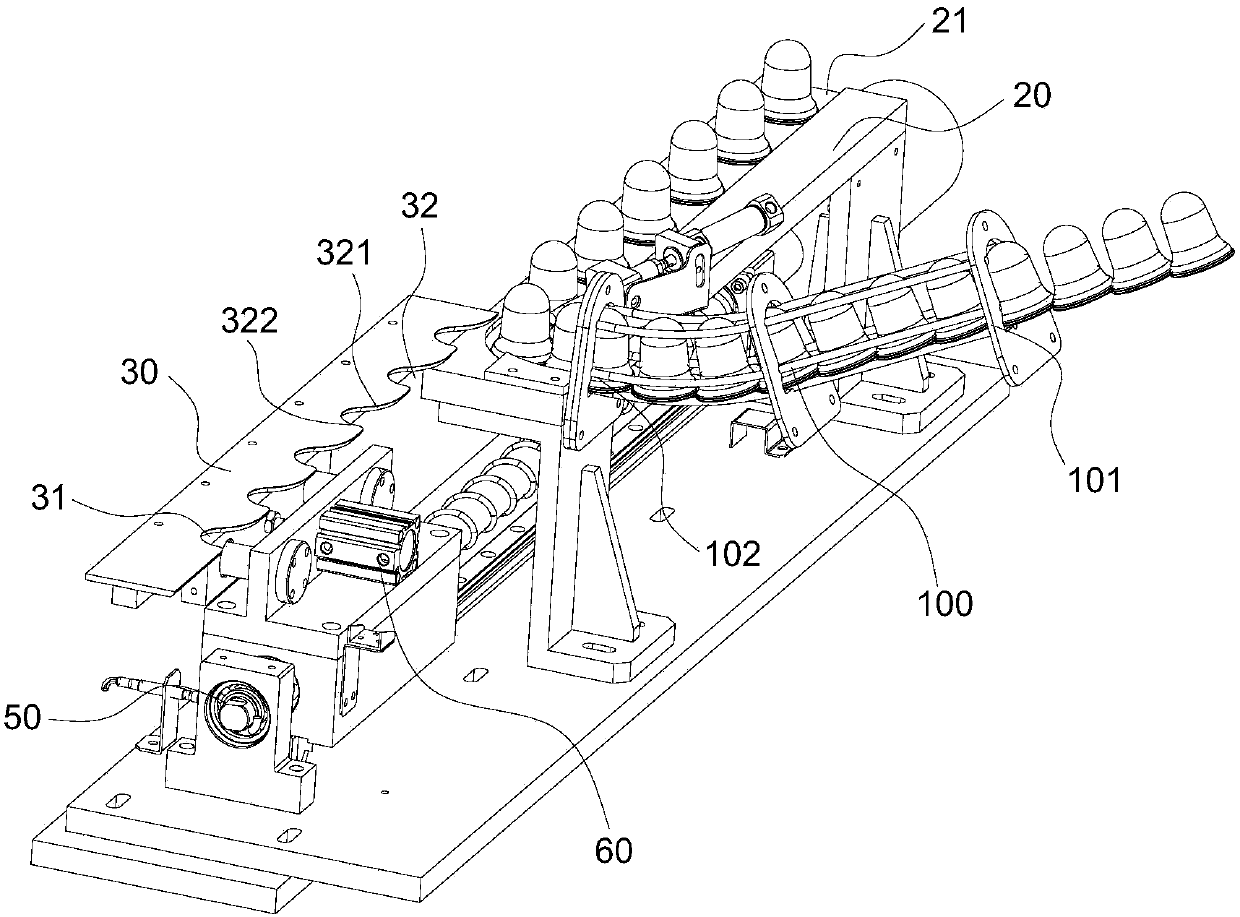

[0026] like Figure 1-4 As shown, a preform loading device includes a frame 10, on which a feeding station and a compacting station 11 are arranged; The slideway 20 is used to receive the divided preform; the divided base plate 30 is installed on the frame 10, and the divided base plate 30 is provided with a plurality of divided parts arranged at equal intervals, and the plurality of divided parts are used for The preforms of the loading station are successively clamped onto the distribution slide 20; the clamping part 40 is installed on the frame 10 and is located above the distribution slide 20, and the clamping part 40 is used for clamping the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com