Concrete prefabricated part troweling device

A prefabricated part and concrete technology, applied in manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of inability to remove leftovers and affect the molding of concrete prefabricated parts, and achieve the effect of ensuring molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

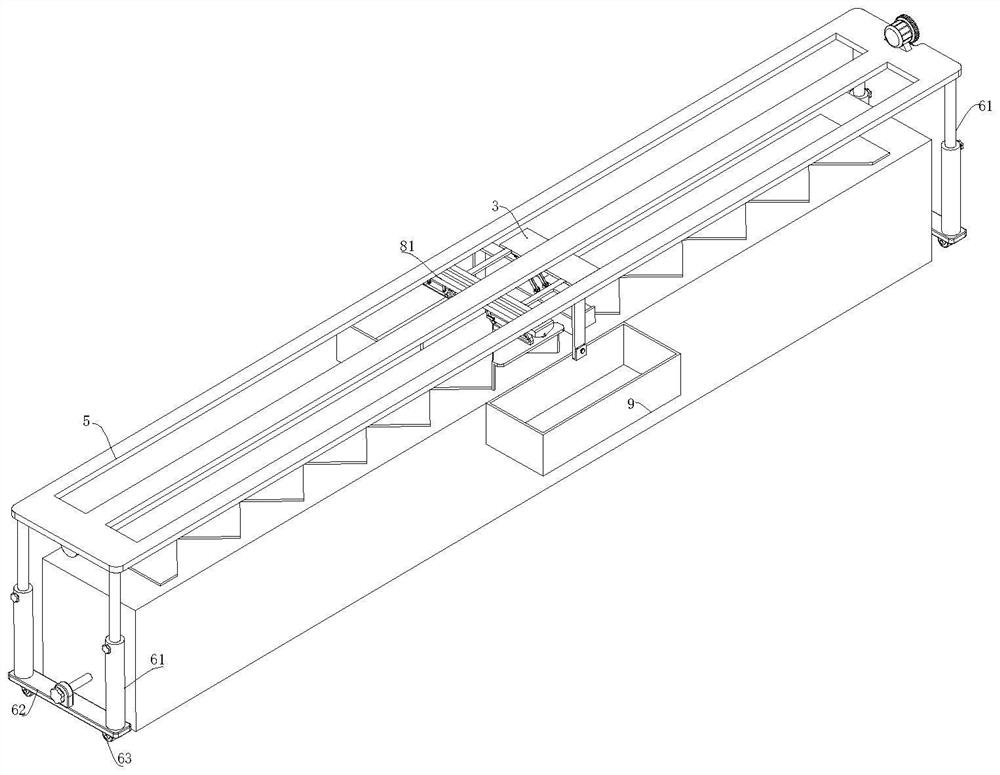

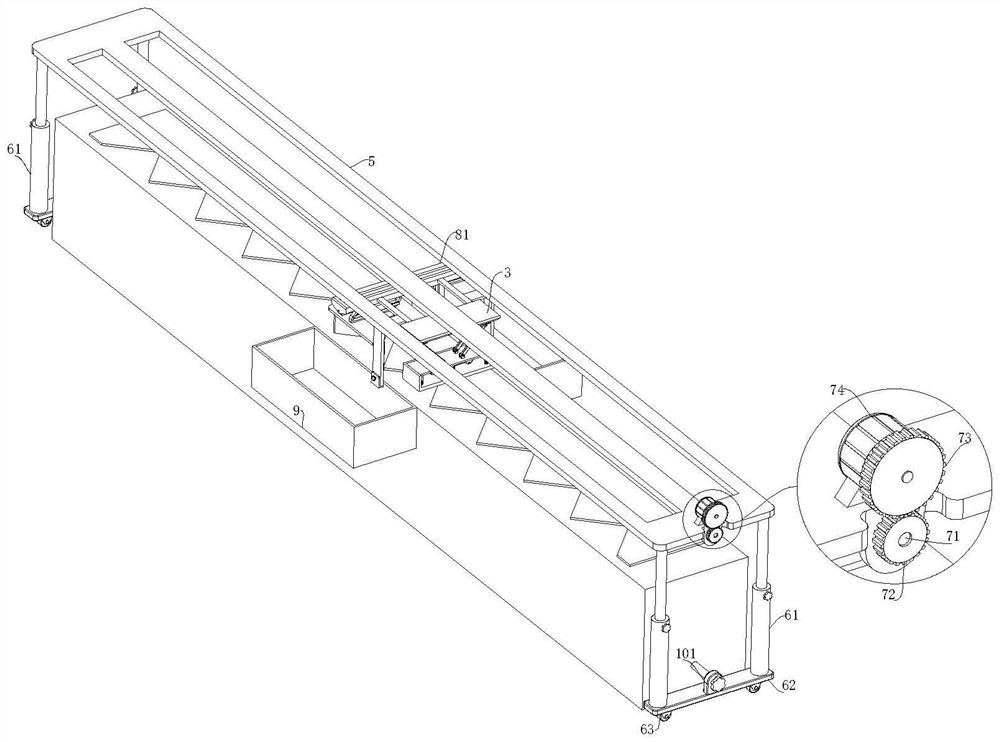

[0046] A concrete prefab troweling device, comprising a trowel 1 for troweling a prefabricated concrete staircase, a connecting mechanism 2 is installed inside the enclosure plate 11 and located on the trowel 1, and the connecting mechanism 2 is used to make the trowel 1 Auxiliary troweling of the concrete on one side of the mold;

[0047] The connecting mechanism 2 includes a fixing plate 21 arranged inside the enclosure plate 11 and located above the troweling plate 1, and the adjusting mechanism 4 is connected with the fixing plate 21. The four corners of the bottom of the fixing plate 21 are provided with buffer members 22, and the buffer members 22 are connected to the wiping plate 21. Light board 1 connection;

[0048] A pusher 23 for pushing the trowel 1 is installed at the bottom of the fixing plate 21;

[0049] The buffer member 22 includes a buffer sleeve 221 fixedly connected to the bottom of the fixing plate 21 , and a buffer rod 222 is slidably penetrated through...

Embodiment 2

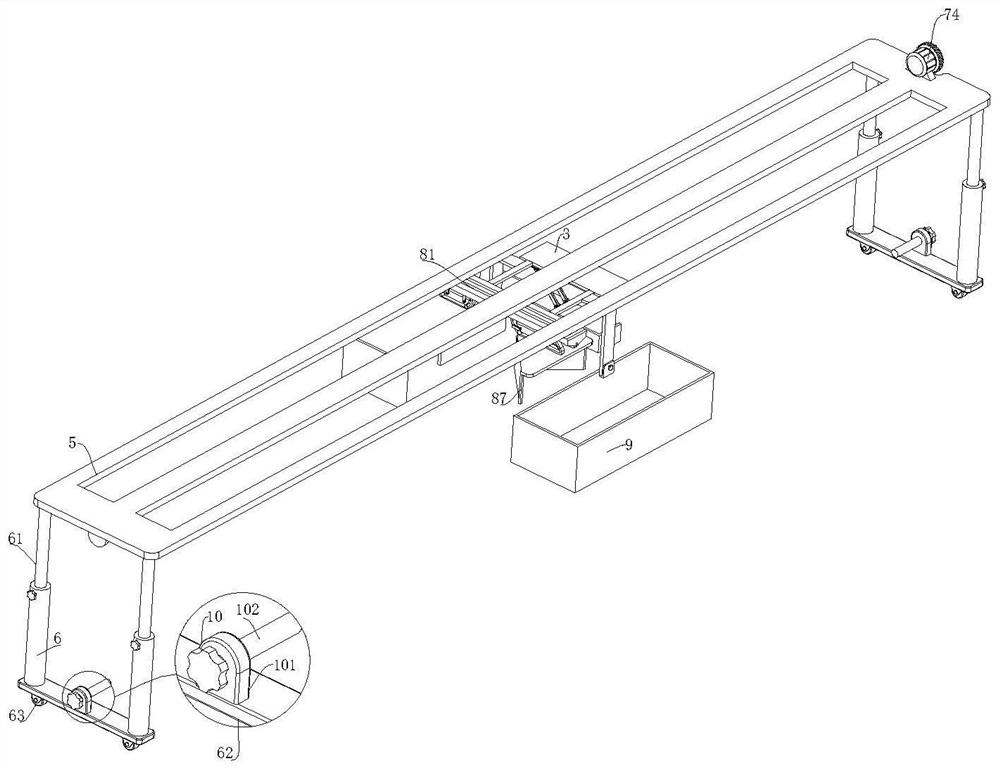

[0067] Embodiment 2: Based on Embodiment 1, a positioning mechanism 10 is also installed on the support plate 62. The positioning mechanism 10 is used to align the support frame 5 relative to the mold. The positioning mechanism 10 includes a positioning plate 101 fixedly connected to the support plate 62. , the positioning plate 101 is provided with a threaded hole, and the threaded hole has a locking screw 102, one end of the locking screw is fixed with a handle, and the mold is provided with a locking hole at the position corresponding to the locking screw 102, so that when the support frame 5 moves to the When the mold is above the mold, by locking the screw 102, not only the support frame 5 is aligned with respect to the mold, but also the support plate 62 is stably fixed with respect to the mold to prevent the phenomenon of deviation when the concrete prefabricated stairs are troweled. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com