Kitchen air conditioning system

A technology for air conditioning systems and kitchens, applied in air conditioning systems, ventilation systems, kitchen cabinets, etc., can solve the problems of reducing the energy efficiency of air conditioners, the volume of kitchen air conditioners cannot be too large, and the structure is not compact enough, so as to improve work efficiency and work life, improve Refrigeration/heating efficiency, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

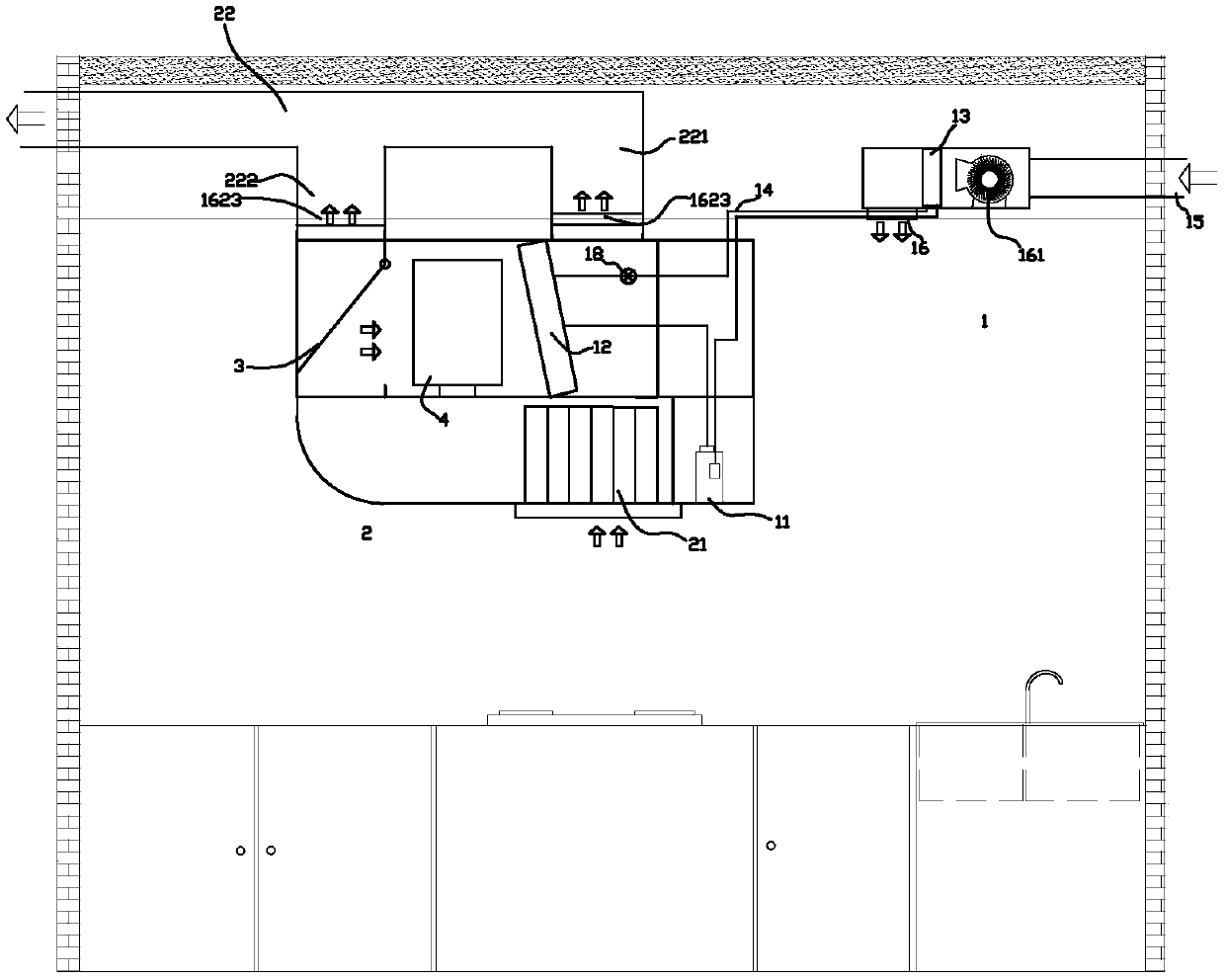

[0114] Such as figure 1 with figure 2 As shown, the kitchen air conditioning system of this embodiment includes an air conditioning assembly 1 and a range hood assembly 2 . Wherein, the air conditioning assembly 1 includes a compressor 11, a first heat exchanger 12 and a second heat exchanger 13, and the compressor 11, the first heat exchanger 12 and the second heat exchanger 13 are connected through a refrigerant pipeline 14, A throttling valve 18 is installed on the refrigerant pipeline 14 between the first heat exchanger 12 and the second heat exchanger 13 , and a four-way valve (not shown) is installed on the refrigerant pipeline 14 . By switching the four-way valve, it is possible to switch between the cooling mode and the heating mode. In the cooling mode, the first heat exchanger 12 is a condenser, and the second heat exchanger 13 is an evaporator. In the heating mode, the first heat exchanger The device 12 is an evaporator, and the second heat exchanger 13 is a cond...

Embodiment 2

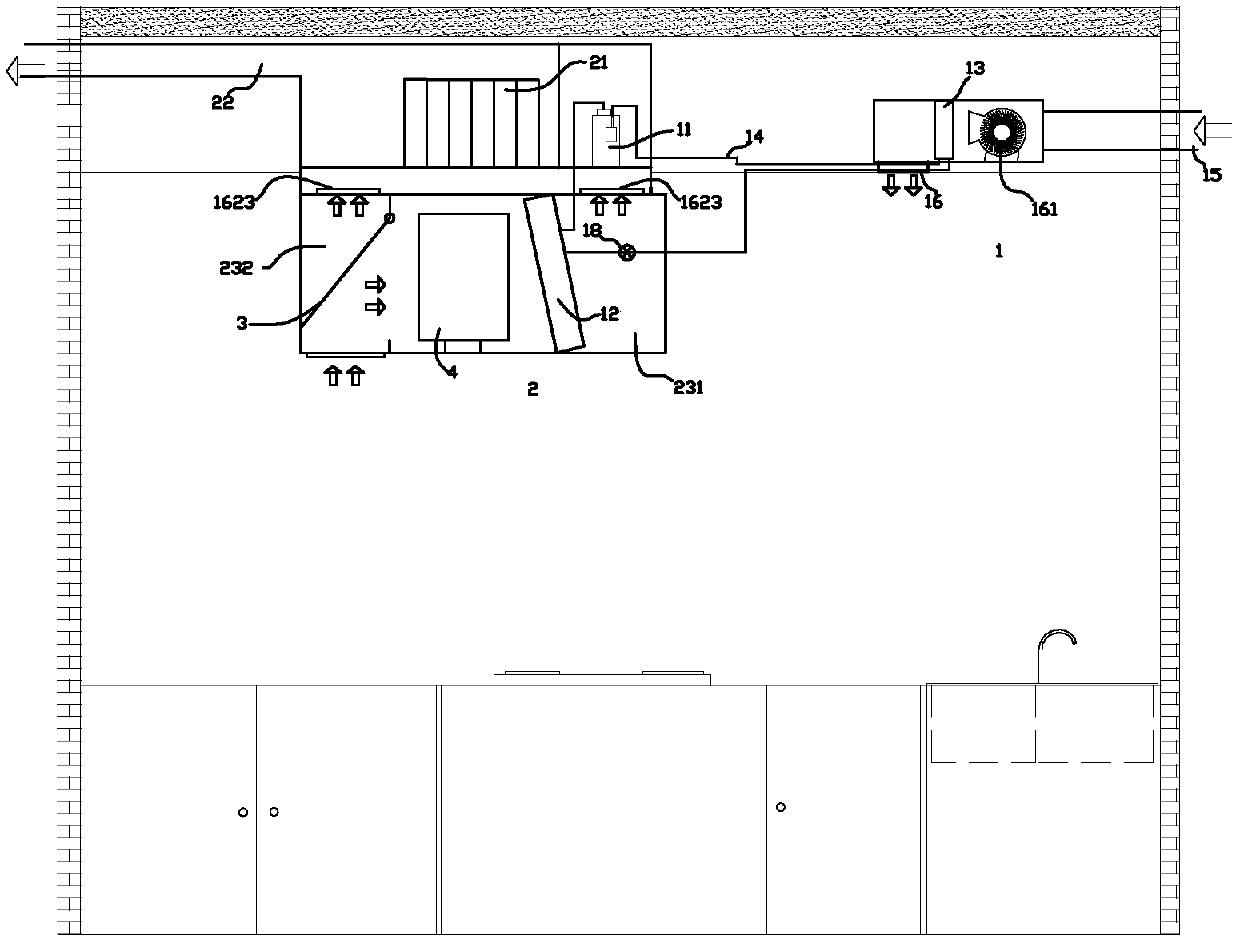

[0124] like figure 2 As shown, the air inlet passage 23 forms the first air inlet passage 231 and the second air inlet passage 232 through the bifurcation opening, and a switching valve 3 is arranged at the bifurcation opening, by switching the switching valve 3, the first smoke exhaust passage 231 communicates with the air outlet of the fan or connects the second exhaust channel 232 with the air outlet of the fan. When the air valve is on the right side, the range hood works alone, and the air conditioning system does not start; the other is when the air valve is on the left side, to achieve the effect of exhausting oil fume and air conditioning at the same time. In this way, when heating or cooling is not required, the heat exchange component can be free from oil fume pollution, which helps to increase its working life.

Embodiment 3

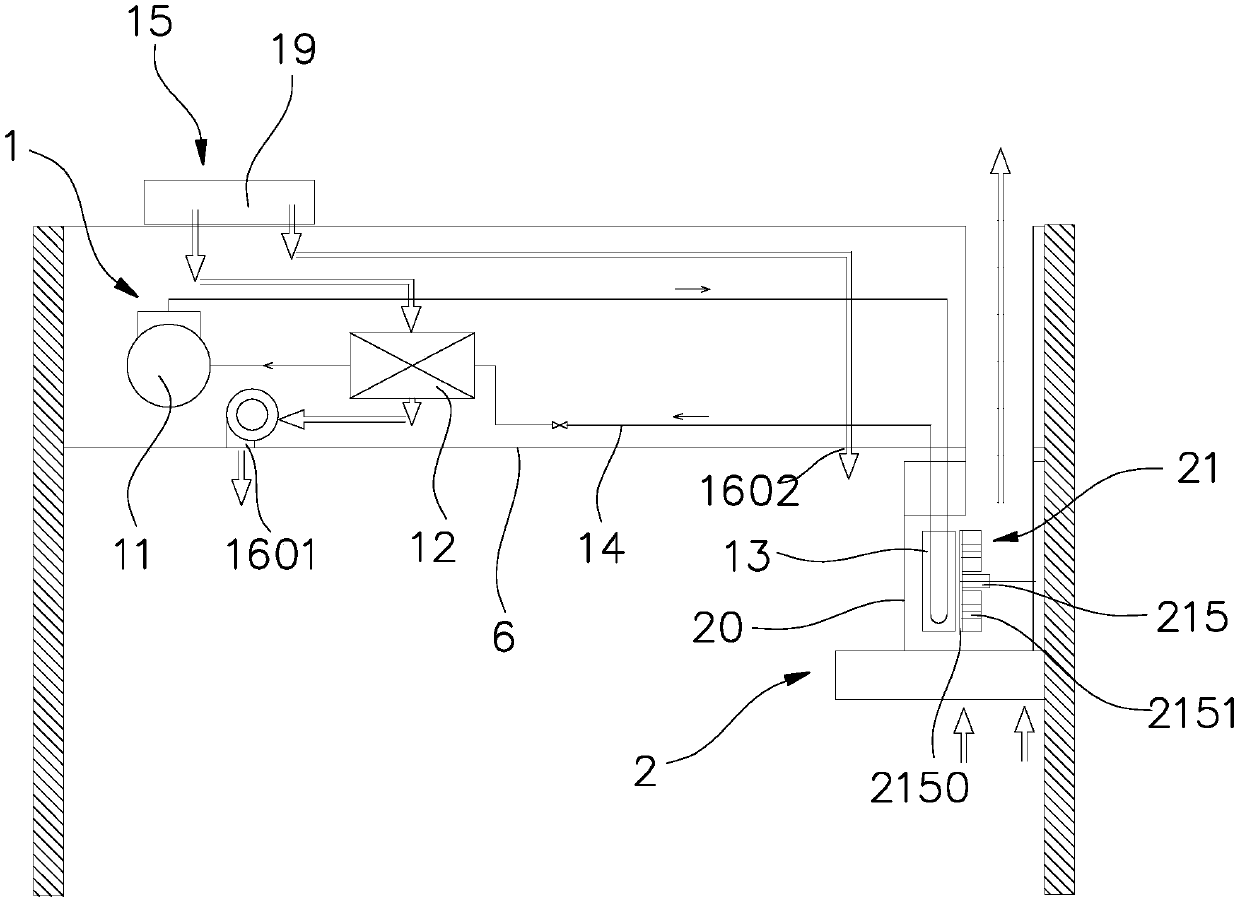

[0126] like image 3 As shown, the kitchen air conditioning system in this embodiment includes an air conditioning assembly 1 and a range hood 2 . The air conditioning assembly 1 includes a compressor 11, a first heat exchanger 12 and a second heat exchanger 13, and the compressor 11, the first heat exchanger 12 and the second heat exchanger 13 are connected through a refrigerant pipeline 14, The working principle of the air-conditioning assembly 1 is the same as that of the existing air conditioner, so it will not be described here. The range hood 2 includes a hood casing 20 and a fan assembly 21 disposed inside the hood casing, and the second heat exchanger 13 is disposed inside the fan assembly 21 so that the air conditioning assembly 1 and the range hood 2 communicate with each other.

[0127] Fan assembly 21 comprises motor 215, impeller chassis 2150 and impeller 2151, and impeller chassis 2150 is installed on the output shaft of motor 215, and impeller 2151 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com