Automatic cooker

An automatic cooking and chassis technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of manual feeding, increase the work intensity of operators, and no treatment, so as to eliminate oil fume pollution, realize industrialization and standardization, and reduce life. garbage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments:

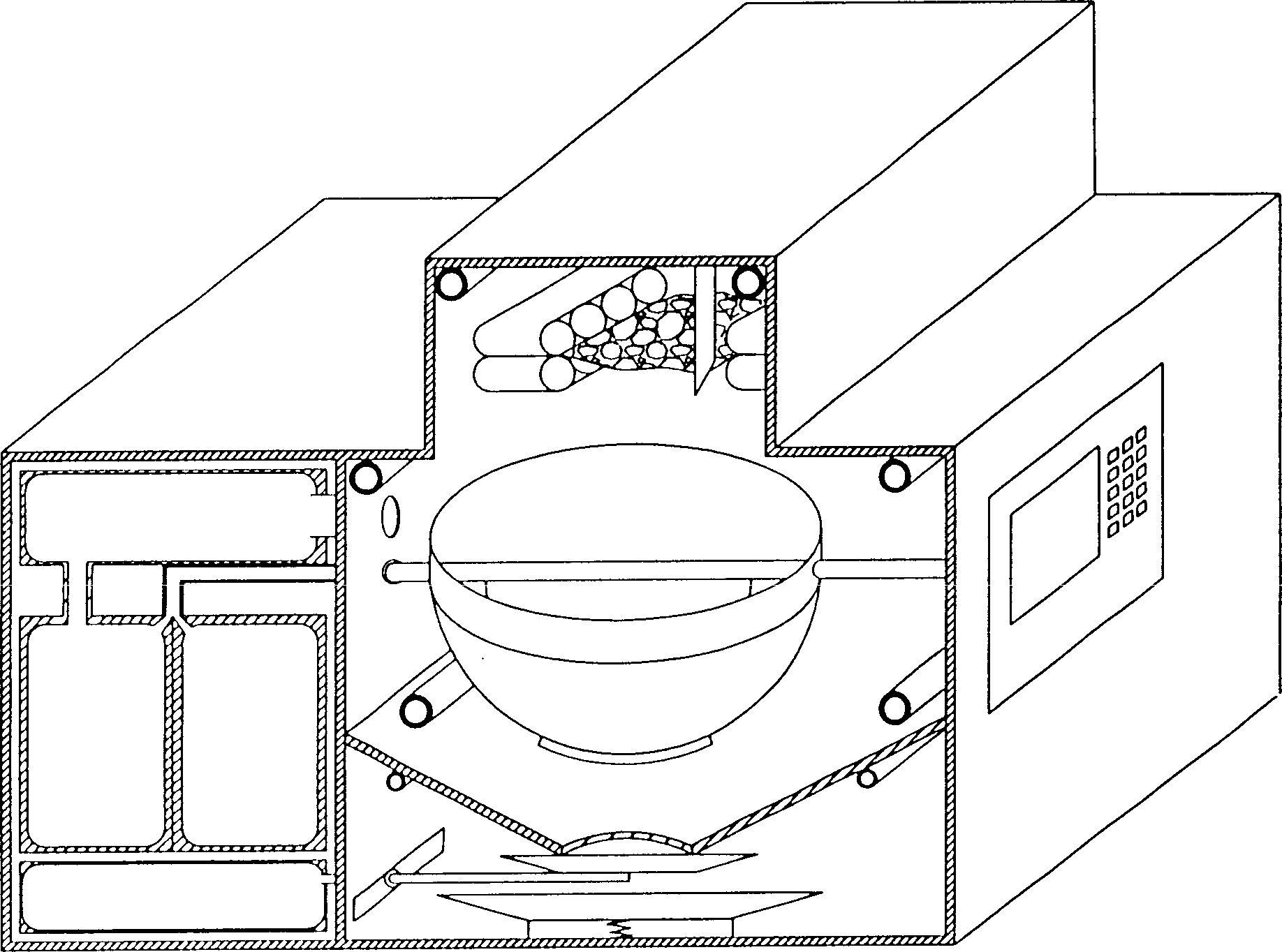

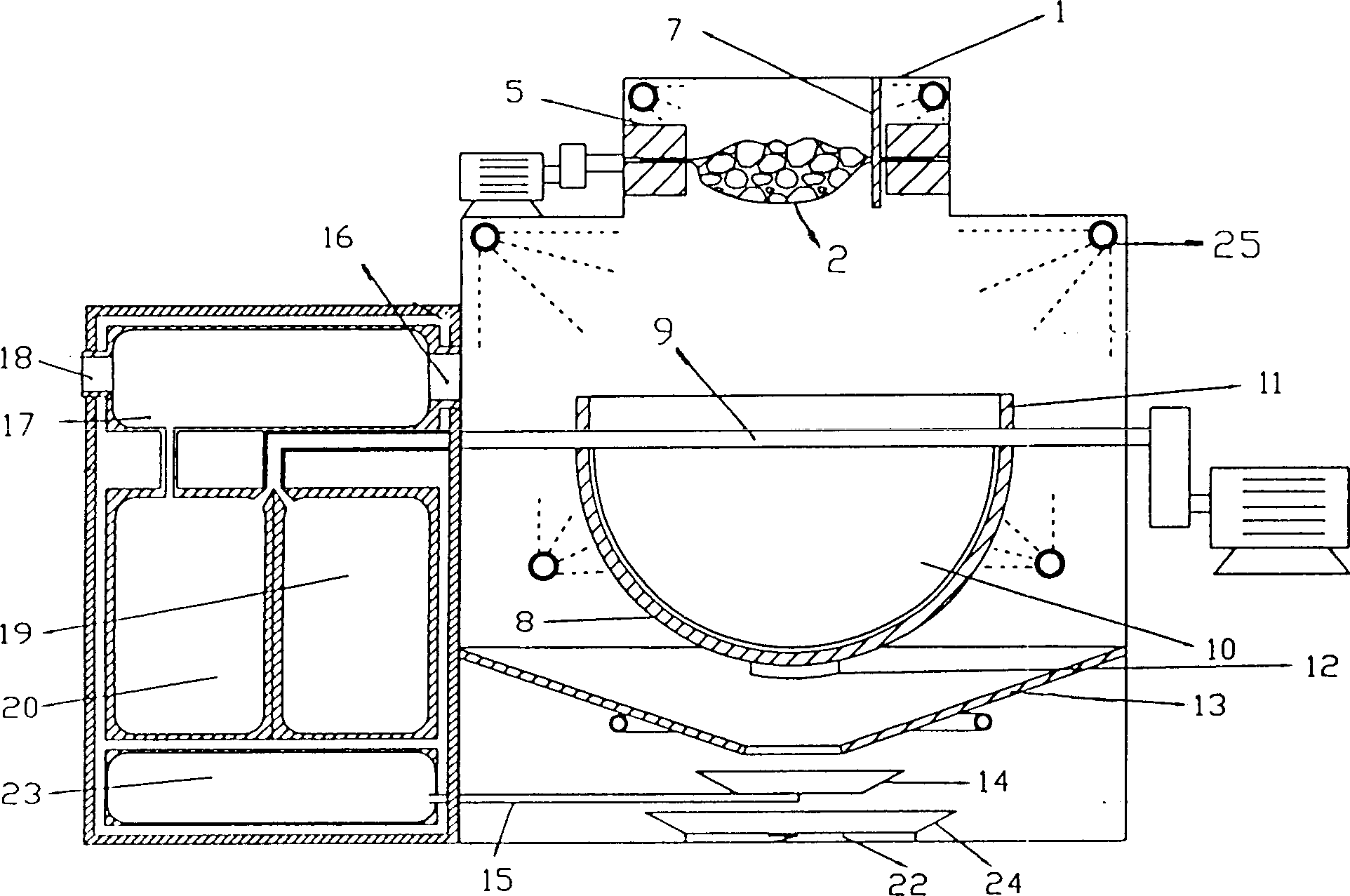

[0021] Such as figure 1 with figure 2 As shown, it roughly shows the structure of the automatic cooking machine of this embodiment. The interior of the cabinet shell 1 of the automatic cooking machine can be divided into: feeding device, cooking device, tray-out device and purifying device according to functions. The control device is arranged on the cabinet shell 1, and it can also be separately arranged outside the cabinet shell. .

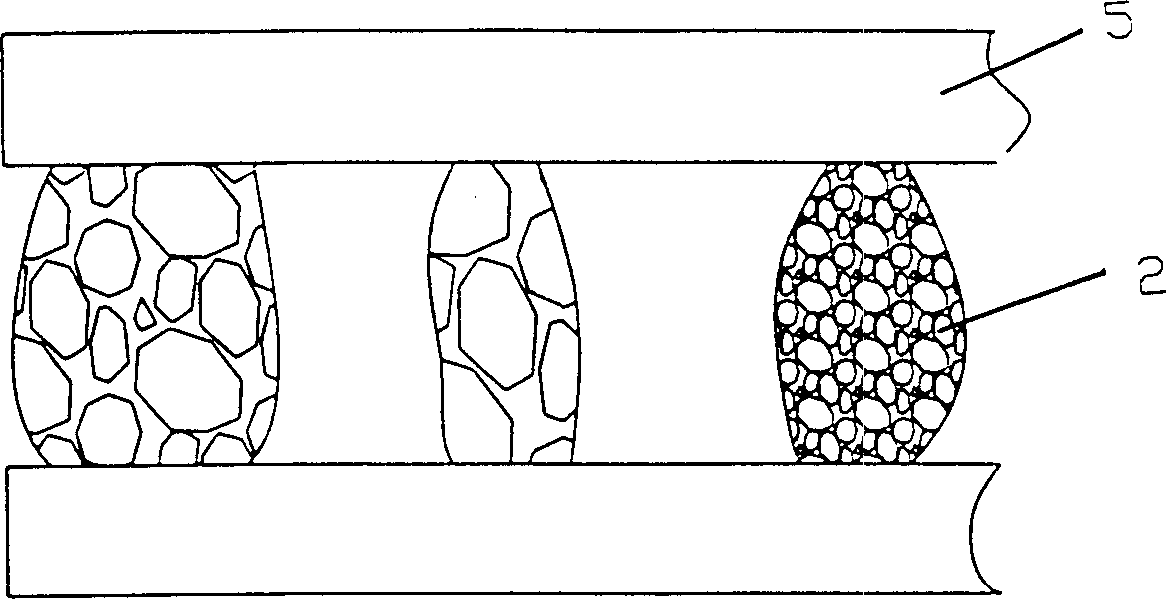

[0022] The raw materials used in cooking are selected, washed and cut in a special food processing site, and sealed in the raw material package 2. Such as image 3 with Figure 4 As shown, the transmission system can transport the raw material package 2 clamped between the two conveyor belts 5 to the top of the pot body 8. Each conveyor belt 5 includes two conveyor belts. The conveyor belts cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com