A kind of artificial lawn preparation method

A technology of artificial turf and turf, applied in roads, pavements, non-polymer adhesive additives, etc., can solve the problems of glue penetration, affecting the comprehensive performance of turf, and grass sticking, so as to reduce grass damage and avoid oily smoke Pollution, the effect of the right consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

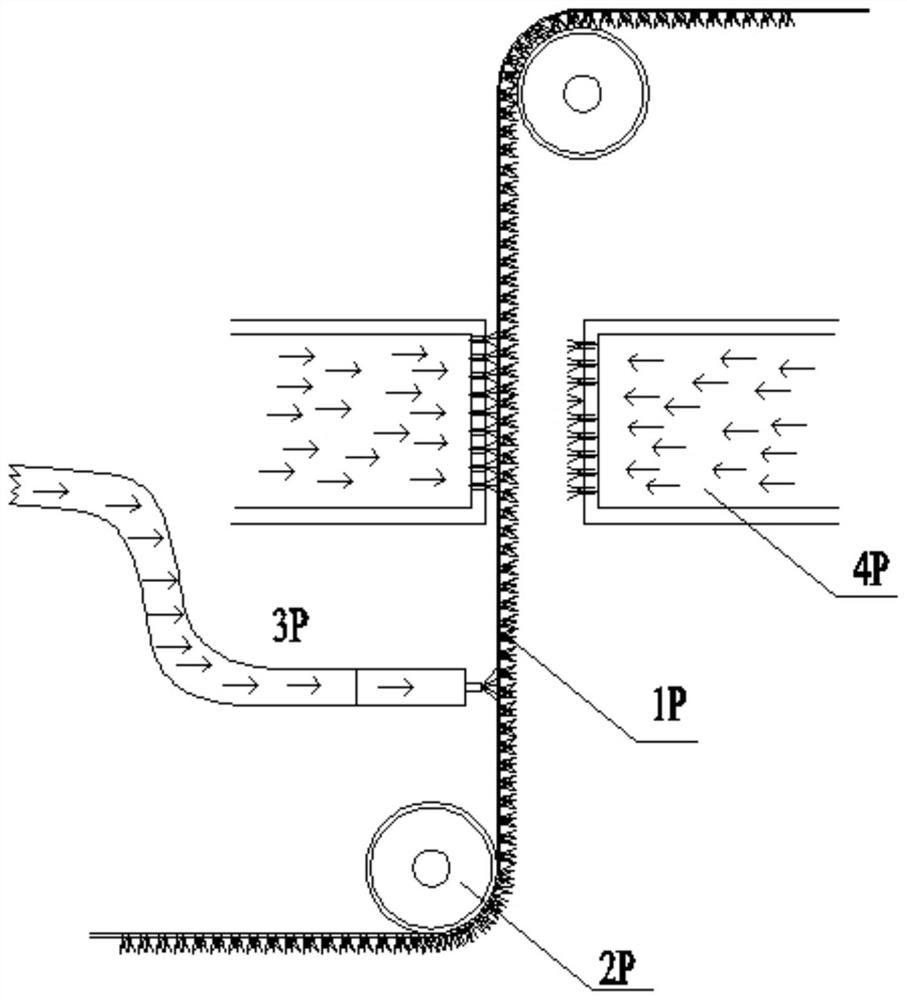

[0035] like figure 1 As shown, a method for preparing artificial turf of the present invention comprises the following steps:

[0036] Step 1: Weaving artificial grass fibers onto the lawn base cloth to form semi-finished lawn 1P;

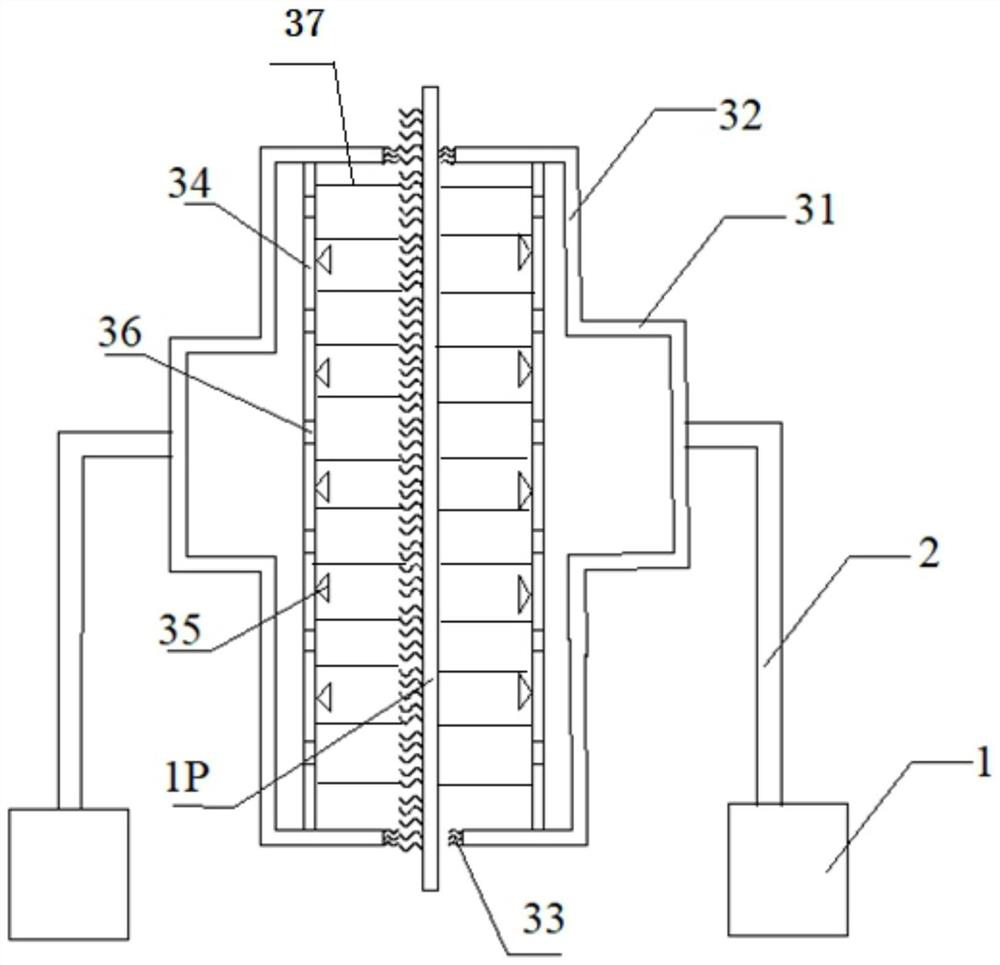

[0037] Step 2: Use the rolling of at least one guide roller 2P to drive the semi-finished lawn 1P to move vertically, and during the movement of the semi-finished lawn 1P, first spray the glue 3P on one side of the semi-finished lawn 1P where artificial grass fibers are woven , and then use the hot air 4P to heat and solidify the semi-finished lawn after spraying the glue to obtain the finished artificial lawn;

[0038] Wherein, along the moving direction of the semi-finished lawn 1P, a needle is provided on the surface of one of the guide rollers in front of the glue spraying, and the carpet back of the semi-finished lawn is punched during the rolling process of the guide roller 2P, Several drainage holes are formed on the carpet back of the sem...

Embodiment approach

[0040] According to a preferred embodiment of the present invention, the intervals of the guide rollers are vertically distributed, and the semi-finished lawn passes through the surfaces of the different guide rollers in turn. The guide rollers are driven by external power to roll, and the With the rolling of the guide roller, the semi-finished lawn moves.

[0041] In the above technical solution, the above-mentioned guide rollers are rolling while punching the carpet back of the semi-finished lawn, which is more efficient, and uses physical puncturing, so that the carpet back of the artificial lawn is covered with countless small and micro holes. It replaces the traditional electric iron to punch holes, reduces the damage of grass silk, eliminates the emission of waste gas and oil fume produced by electric soldering iron punching, reduces environmental pollution, and thus achieves environmental protection in the production process of artificial turf.

[0042] According to a p...

Embodiment 1

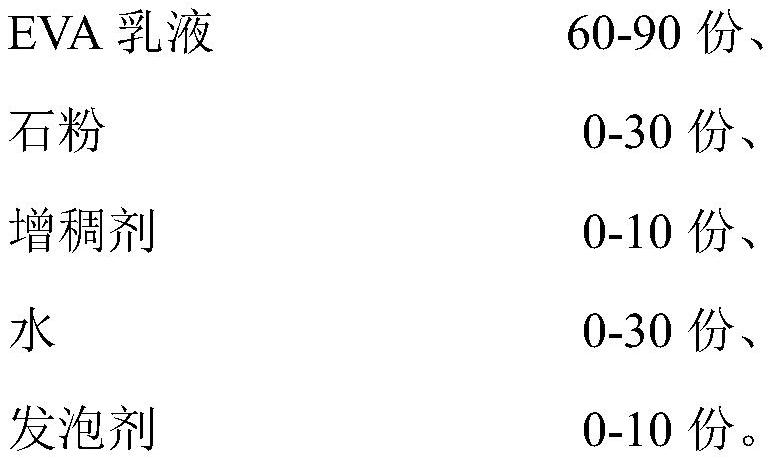

[0065]

[0066] The foaming agent is sodium lauryl sulfate; the thickener is a cross-linked polymer emulsion thickener containing an acidic group.

[0067] Mix the EVA emulsion and water of the above-mentioned parts by weight, mix well, and then add the foaming agent, lime and thickener of the above-mentioned parts by weight to it to obtain the glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com