Process for upgrading low-rank coal in an internally heating way with heated gas carrier

An internal heating, low-rank coal technology, used in solid fuels, petroleum industry, special forms of dry distillation, etc., can solve the problems of complex equipment supporting systems, high requirements for factory construction, and small processing coal volume, and achieve process technology adaptability Good, low particle size requirement of raw coal, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

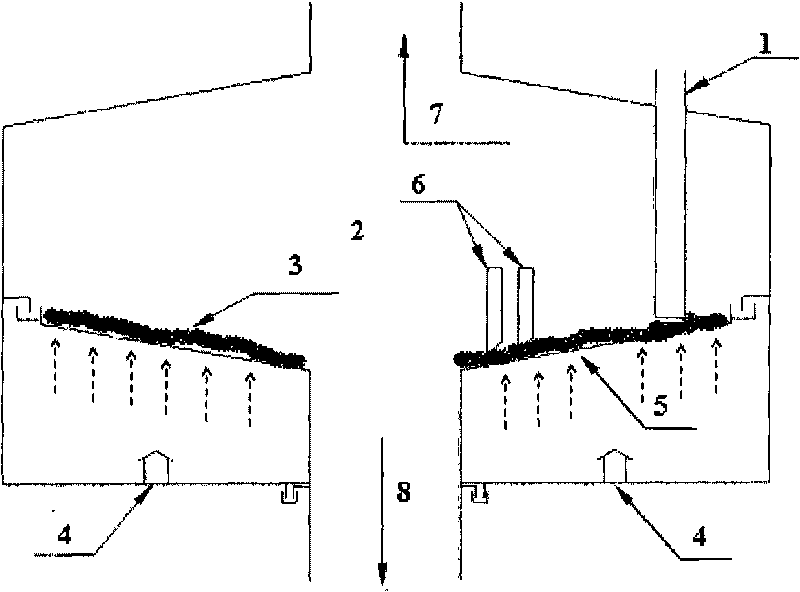

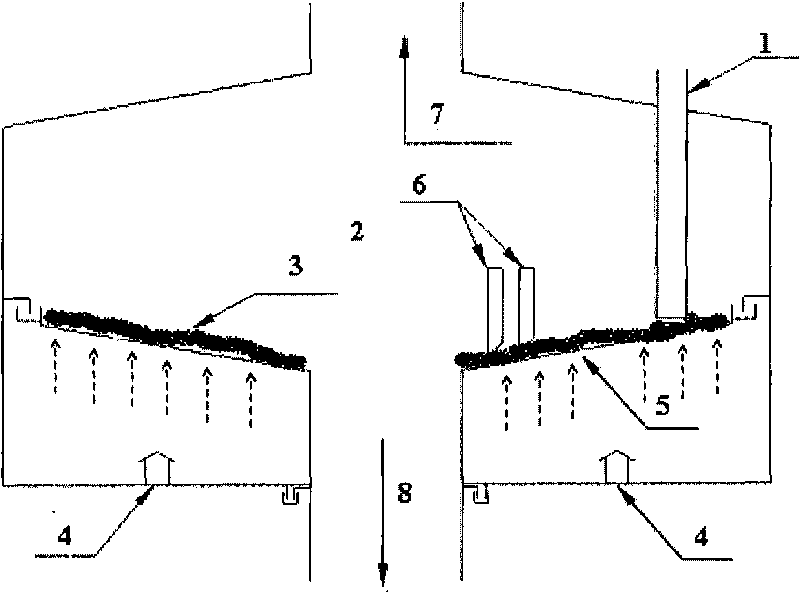

[0029] Such as figure 1 As shown, the crushed and sieved raw coal with a particle size distribution of 6-50 mm is added to the rotary grate 5 of the reactor 2 through the raw coal feed chute 1, and the falling point of the feed chute is the same as that between the grate. The distance between them is the thickness of the treated coal seam, and the anaerobic heating gas with an oxygen content below 1% enters from the hot gas inlet 4 arranged under the reactor 2, and directly contacts the coal sample 3 through the holes on the grate for heat transfer , drying or pyrolysis reaction occurs, after a certain reaction time, with the rotation of the rotary grate 5, the treated coal sample is scraped to the discharge port 8 by the plow mechanical agitator 6 fixedly arranged above the rotary grate 5, and enters To the next process, the hot gas tail gas is discharged through the exhaust outlet 7.

[0030] In the following, a specific example will be used for illustration.

[0031] Demo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com