Desert sand lightweight aggregate concrete special-shaped column structure with built-in insulation board and construction process of desert sand lightweight aggregate concrete special-shaped column structure

A technology of lightweight aggregate concrete and thermal insulation board, applied in thermal insulation, columns, piers and other directions, can solve the problems of energy waste, heavy structural burden, prone to cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

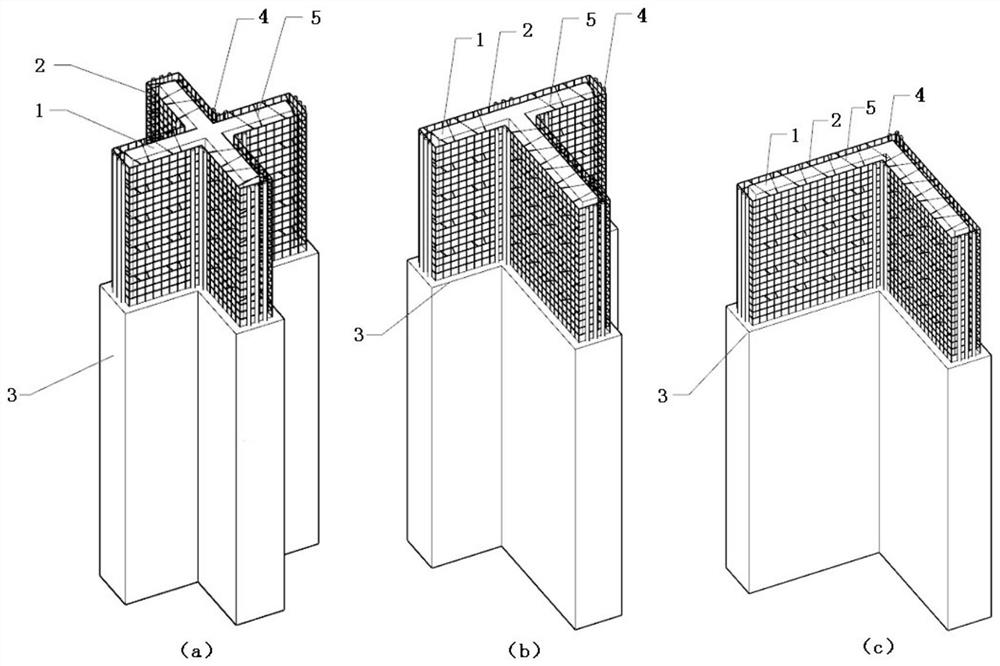

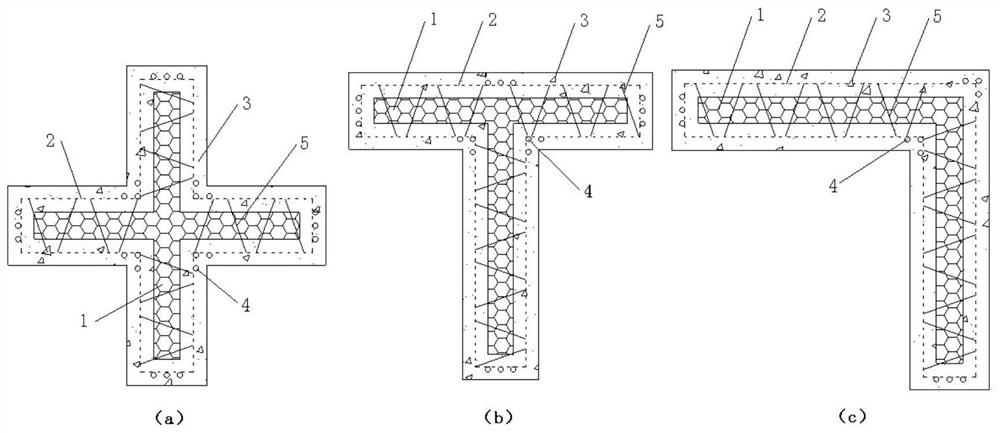

[0033] A construction technology of desert sand lightweight aggregate concrete special-shaped column structure with built-in insulation board, the specific steps are as follows:

[0034] Step 1. Cut the entire steel wire grid and insulation board according to the design requirements, and glue them together to form a cross-shaped insulation board 1, and then use gas shielded welding to weld the cut steel wire grid interface to make ten Zigzag wire mesh frame 2;

[0035] Step 2, using gas shielded welding to weld the longitudinal stress reinforcement 4 at the end and core of the cross-shaped steel wire grid 2, so that the longitudinal stress reinforcement 4 and the cross-shaped steel wire grid 2 are connected;

[0036] Step 3. Install the cross-shaped column mold outside the structure completed in Step 2. The water-binder ratio is 0.5, and the volumetric sand ratio is 39%. In each cubic meter of raw materials, cement is 260.1Kg / m3 and fly ash is 45.9Kg / m3 , ceramsite 463Kg / m3, ...

Embodiment 2

[0039] A construction technology of desert sand lightweight aggregate concrete special-shaped column structure with built-in insulation board, the specific steps are as follows:

[0040] Step 1. Cut the entire steel wire grid and insulation board according to the design requirements, and glue them together to form a T-shaped insulation board 1, and then use gas shielded welding to weld the cut steel wire grid interface to form a T Shaped wire mesh frame 2;

[0041] Step 2, using gas shielded welding to weld the longitudinal stress reinforcement 4 at the end and core of the T-shaped steel wire grid 2, so that the longitudinal stress reinforcement 4 and the T-shaped steel wire grid 2 are connected;

[0042] Step 3. Install the T-shaped column mold outside the structure completed in Step 2. The water-to-binder ratio is 0.51, and the volumetric sand rate is 38%; in each cubic meter of raw materials, cement 262Kg / m3, fly ash 47Kg / m3, pottery Grain 467Kg / m3, river sand 463Kg / m3, de...

Embodiment 3

[0045] A construction technology of desert sand lightweight aggregate concrete special-shaped column structure with built-in insulation board, the specific steps are as follows:

[0046] Step 1. Cut the entire steel wire grid and insulation board according to the design requirements, and glue them together to form a T-shaped insulation board 1, and then use gas shielded welding to weld the cut steel wire grid interface to form a T Shaped wire mesh frame 2;

[0047] Step 2, using gas shielded welding to weld the longitudinal stress reinforcement 4 at the end and core of the T-shaped steel wire grid 2, so that the longitudinal stress reinforcement 4 and the T-shaped steel wire grid 2 are connected;

[0048] Step 3. Install the T-shaped column mold outside the completed structure of Step 2. The water-to-binder ratio is 0.46, and the volumetric sand rate is 41%. Among the raw materials per cubic meter, cement 275Kg / m3, fly ash 67Kg / m3, pottery Grain 420Kg / m3, river sand 563Kg / m3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com