Intelligent drainage and mining method of coalbed methane well and intelligent drainage and mining equipment of coalbed methane well immersed pump

A technology for coalbed methane wells and submersible pumps, applied in mechanical equipment, boreholes/well components, pumps, etc., can solve problems such as limited motor speed regulation capacity, reduced heat exchange efficiency, and obstacles to the expansion of coal reservoir depressurization funnels, etc. Achieve the effect of avoiding stress sensitivity and speed sensitivity and prolonging the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

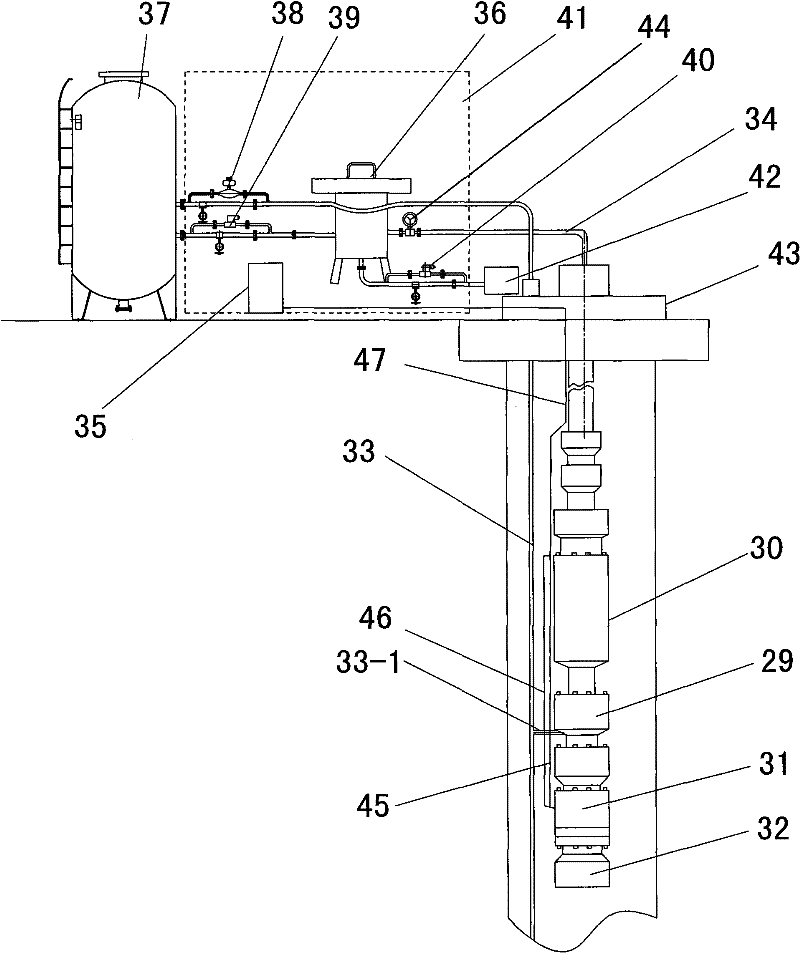

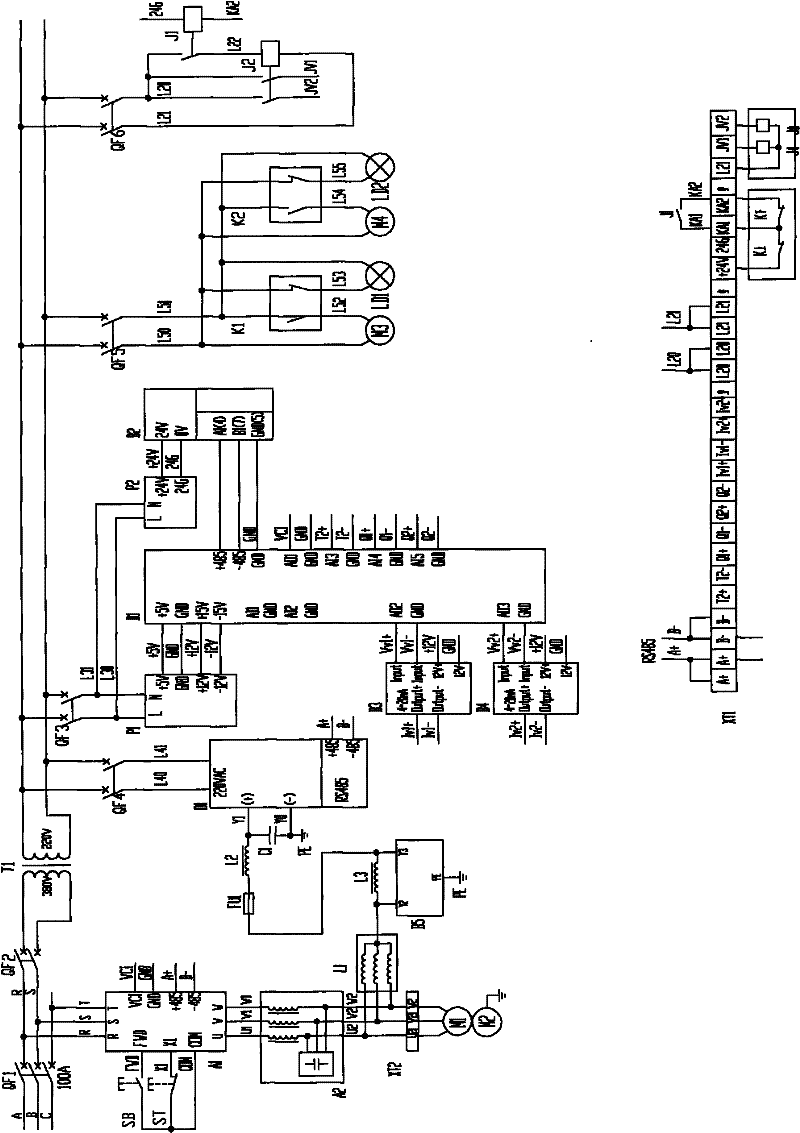

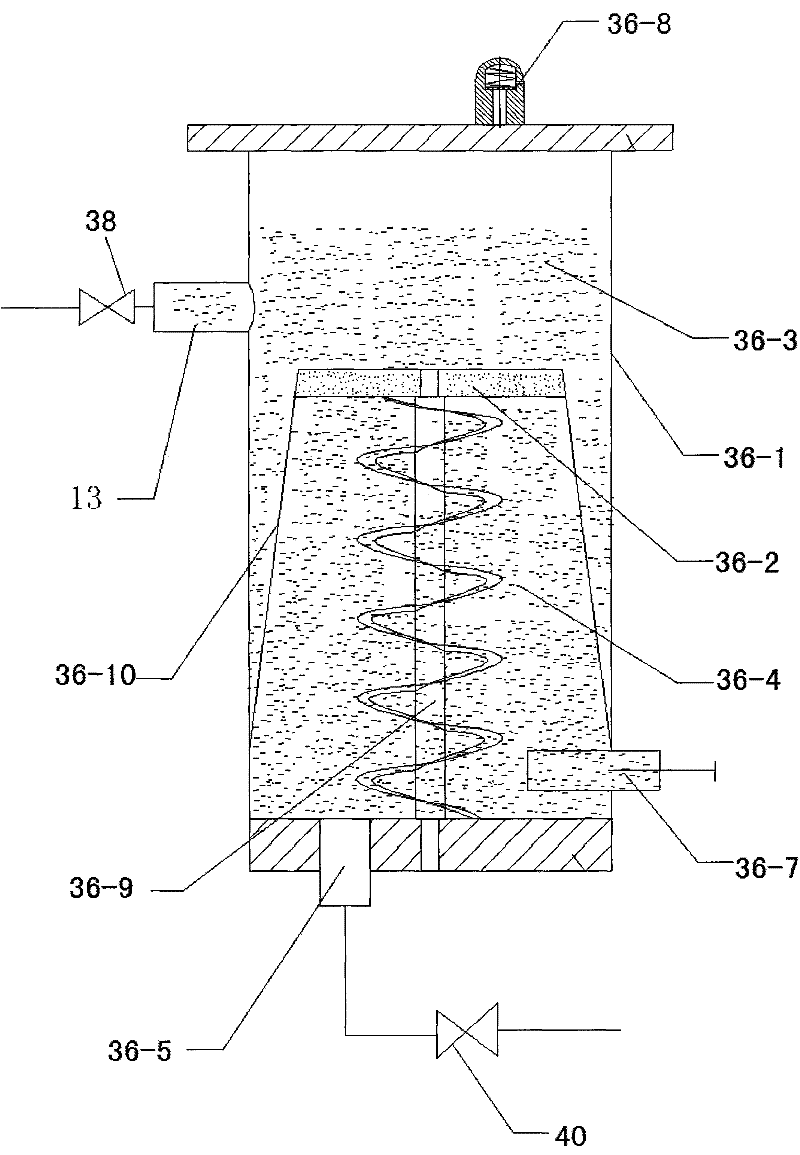

[0026] The coalbed gas well intelligent drainage method of the present invention comprises the following steps:

[0027] (1) Place the pump at a set depth below the liquid level of the downhole liquid in the coalbed methane well, pump the downhole liquid, and control the drop rate of the liquid level linearly through the frequency modulation of the frequency converter and the opening of the drainage electric valve to avoid reservoir stress sensitivity and The speed sensitivity causes damage to the reservoir, so that the downhole liquid level reaches the predetermined value; the coalbed methane well enters the stable production stage, and the motor frequency and the opening of the drainage electric valve are controlled to stabilize the liquid level.

[0028] (2) The downhole liquid pumped out by the pump can be recharged to the coalbed methane well through water quality improvement treatment, and stored in the water storage tank for later use.

[0029](3) During the suction pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com