Medium-temperature SCR denitration system and denitration method for kiln tail flue gas

A denitrification and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of fine dust particles in cement kiln flue gas, clogging of SCR catalyst bed, and limited efficiency of cyclone dust collectors. Improve denitration efficiency and operating life, remove NOx efficiently at low cost, reduce poisoning and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

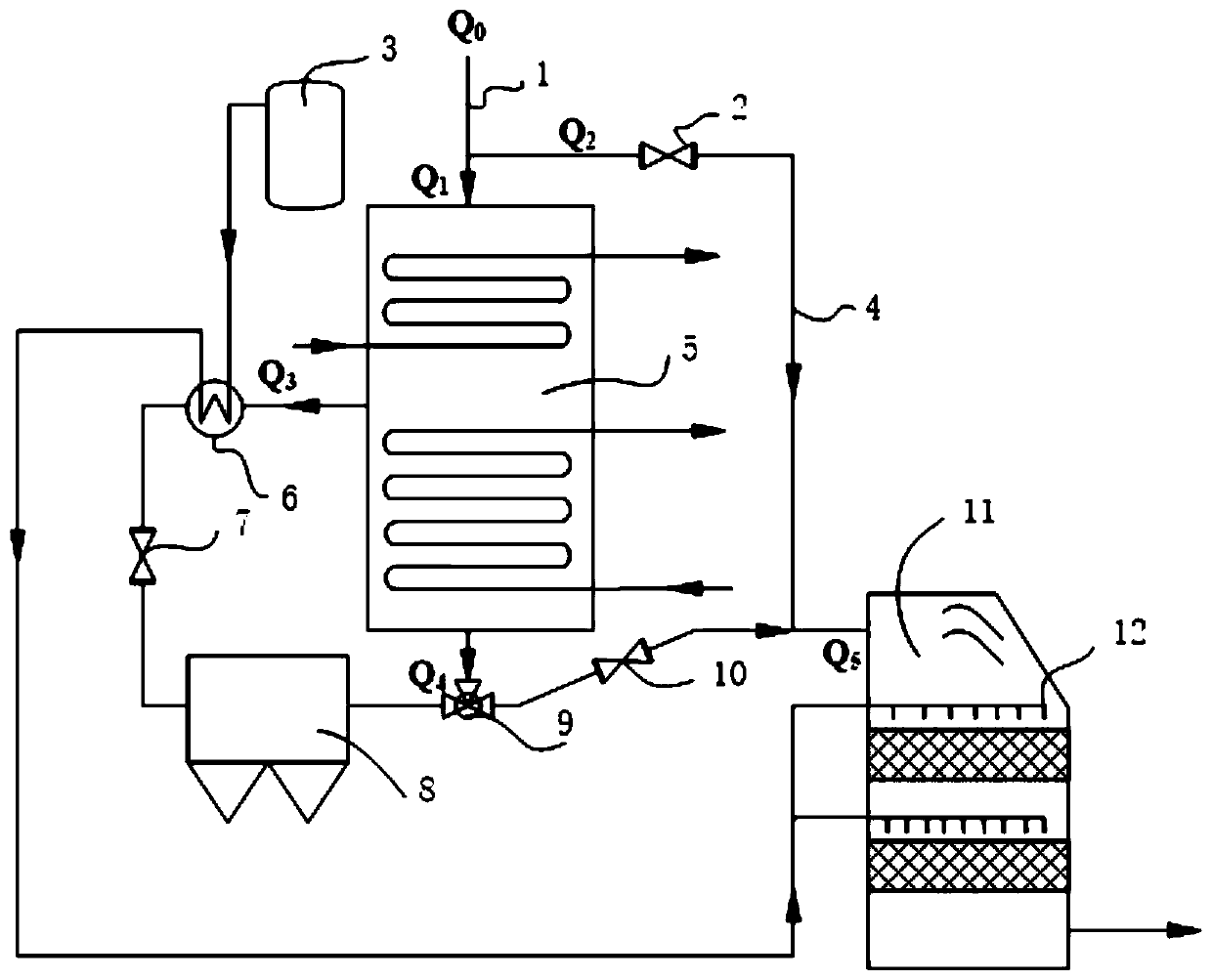

[0090] This embodiment provides a medium-temperature SCR denitrification method for kiln tail flue gas. SCR denitrification is performed on the kiln tail gas discharged from a 3000t / d new dry process cement kiln. The denitrification method specifically includes the following steps:

[0091] (1) Kiln tail gas Q discharged from cement kiln 0 The volume flow rate is 368240Nm 3 / h, kiln tail flue gas Q 0 Medium dust concentration is 50g / Nm 3 , the temperature is 280°C, NO x The concentration is 200mg / Nm 3 , in the kiln tail flue gas Q 0 Before entering the waste heat recovery device 5, the kiln tail flue gas Q 0 Divided into the first kiln tail flue gas Q 1 and the second kiln tail gas Q 2 , the first kiln tail flue gas Q 1 The volume flow rate of kiln tail flue gas Q 0 10% of the total volume flow, that is, the first kiln tail flue gas Q 1 The volume flow rate is 36824g / Nm 3 , the second kiln tail flue gas Q 2 The volume flow rate is 331416g / Nm 3 ;

[0092] The firs...

Embodiment 2

[0097] This embodiment provides a medium-temperature SCR denitrification method for kiln tail flue gas. SCR denitrification is performed on the kiln tail gas discharged from a 3200t / d new dry process cement kiln. The denitrification method specifically includes the following steps:

[0098] (1) Kiln tail gas Q discharged from cement kiln 0 The volume flow rate is 436320Nm 3 / h, kiln tail flue gas Q 0 Medium dust concentration is 60g / Nm 3 , the temperature is 290°C, NO x The concentration is 223mg / Nm 3 , in the kiln tail flue gas Q 0 Before entering the waste heat recovery device 5, the kiln tail flue gas Q 0 Divided into the first kiln tail flue gas Q 1 and the second kiln tail gas Q 2 , the first kiln tail flue gas Q 1 The volume flow rate of kiln tail flue gas Q 0 40% of the total volume flow, that is, the first kiln tail flue gas Q 1 The volume flow rate is 174528g / Nm 3 , the second kiln tail flue gas Q 2 The volume flow rate is 261792g / Nm 3 ;

[0099] The fir...

Embodiment 3

[0104] This embodiment provides a medium-temperature SCR denitrification method for kiln tail flue gas. SCR denitrification is performed on the kiln tail gas discharged from a 3500t / d new dry process cement kiln. The denitrification method specifically includes the following steps:

[0105] (1) Kiln tail gas Q discharged from cement kiln 0 The volume flow rate is 528530Nm 3 / h, kiln tail flue gas Q 0 Medium dust concentration is 70g / Nm 3 , the temperature is 300℃, NO x The concentration is 300mg / Nm 3 , in the kiln tail flue gas Q 0 Before entering the waste heat recovery device 5, the kiln tail flue gas Q 0 Divided into the first kiln tail flue gas Q 1 and the second kiln tail gas Q 2 , the first kiln tail flue gas Q 1 The volume flow rate of kiln tail flue gas Q 0 50% of the total volume flow, that is, the first kiln tail flue gas Q 1 The volume flow rate is 264265g / Nm 3 , the second kiln tail flue gas Q 2 The volume flow rate is 264265g / Nm 3 ;

[0106] The firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com