Cocoon feeding mechanism for silk processing device

A technology for processing equipment and cocoon feeding, which is applied to the field of cocoon feeding mechanism of silk processing equipment, can solve the problems of non-circulating processing cocoon feeding efficiency, unreasonable design and high operating energy consumption, so as to improve dust removal effect, dust removal efficiency and practicality. Strong, improve the effect of conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

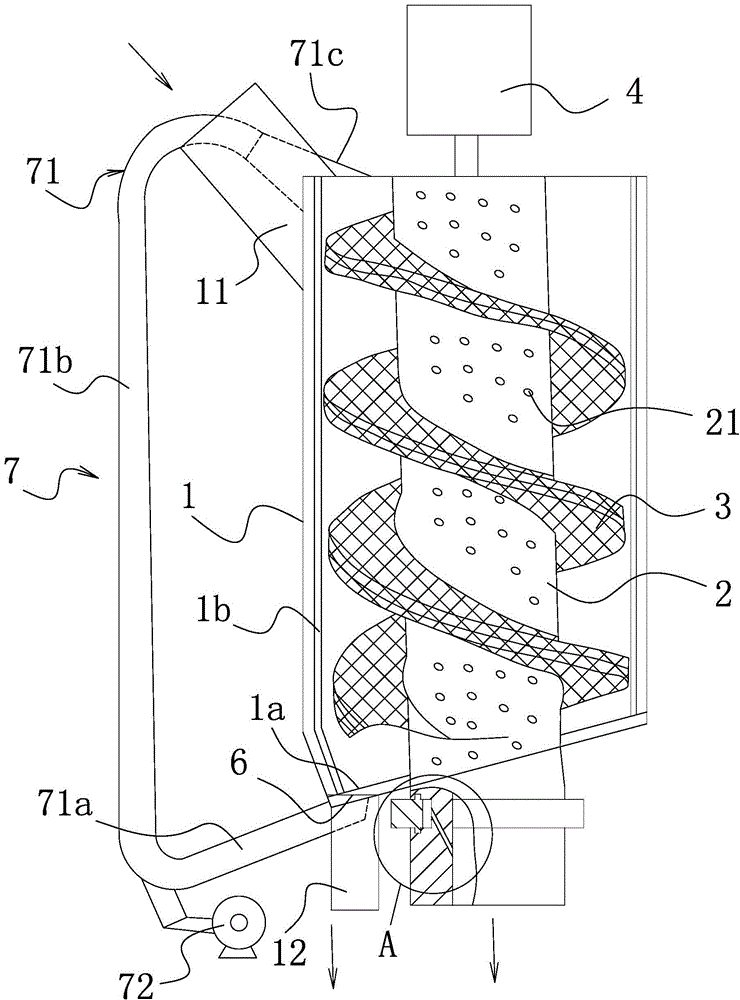

[0024] like Figure 1-3 As shown, the cocoon feeding mechanism of this silk processing equipment comprises a box body 1, an inlet 11 is provided at the top of the box body 1, an outlet 12 is provided at the bottom of the box body 1, and the inner wall of the bottom of the box body 1 has an inclined slope 1a, and the outlet 12 is provided with On the low side of the inclined slope 1a. This structure facilitates cocoon discharge.

[0025] Secondly, the inner wall of the box body 1 is covered with a flexible layer 1b. The flexible layer 1b is made of any one of rubber and silicone. The flexible layer 1b can prevent silkworm cocoons from being damaged.

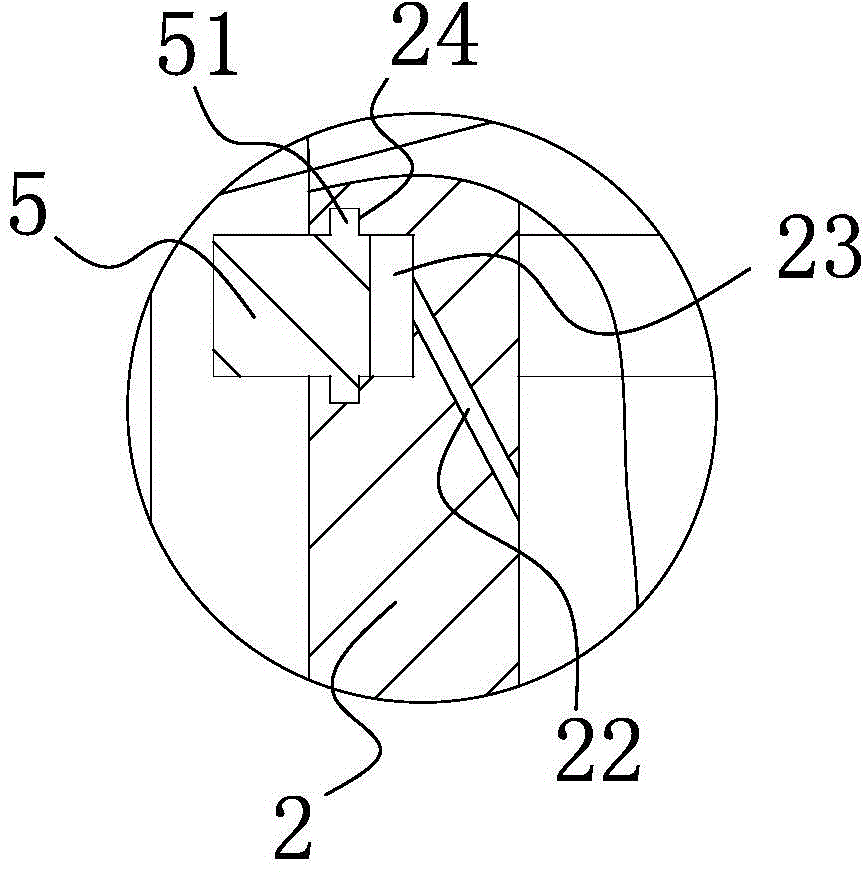

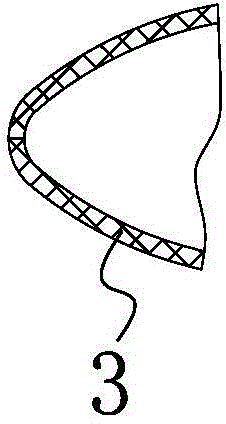

[0026] A cylindrical body 2 arranged vertically is arranged in the box body 1, and a helical blade 3 is arranged on the cylindrical body 2. There is a gap of 1-10 mm between the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com