Horizontal vacuum belt type filter and filtering method thereof

A belt filter, horizontal vacuum technology, applied in the direction of mobile filter element filter, filtration separation, separation method, etc., can solve the problems of uneven feeding, feeding slurry without buffer function, high loss of products to be filtered, etc. It achieves the effects of convenient hoisting and handling, ensuring overflow and feeding efficiency, and ensuring the firmness and reliability of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with a horizontal vacuum belt filter provided by a preferred embodiment of the present invention and the accompanying drawings.

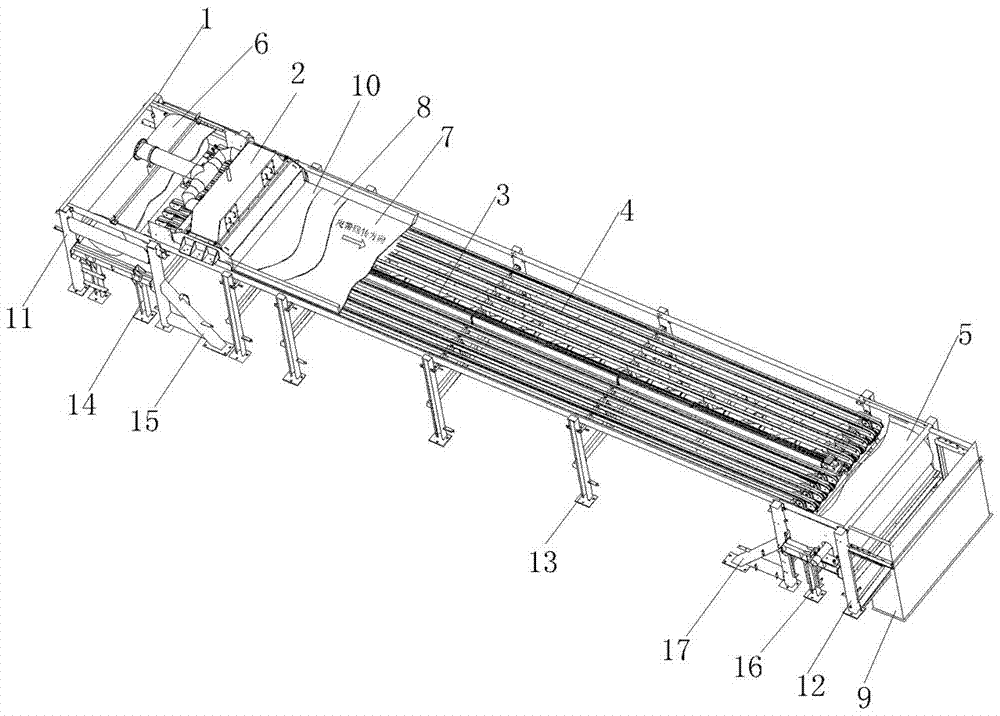

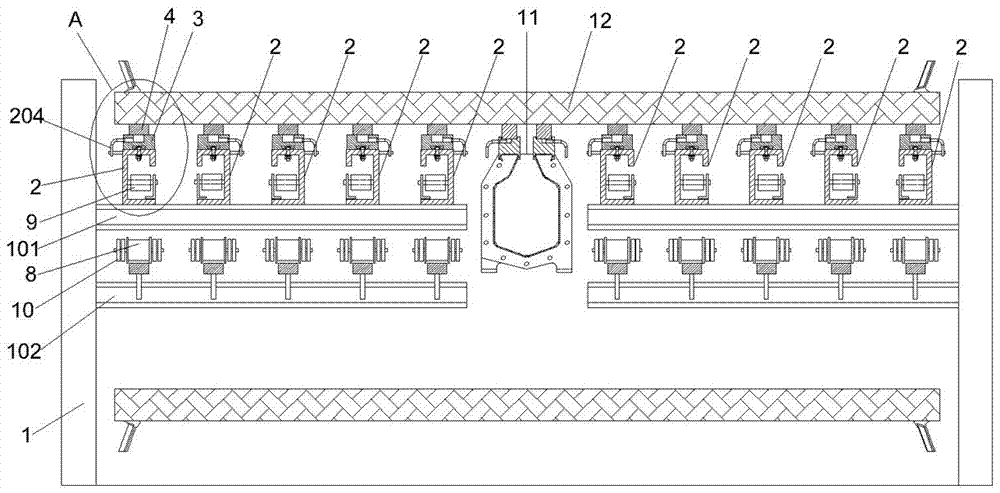

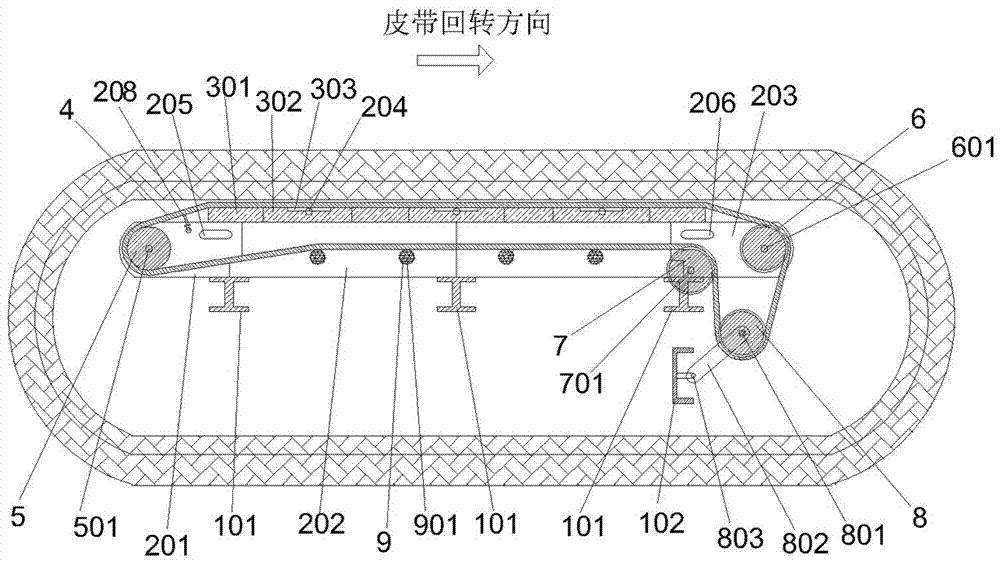

[0058] A kind of horizontal vacuum belt filter provided by the preferred embodiment of the present invention, such as figure 1 As shown, it includes a frame 1 , a driving roller 5 arranged on the frame 1 , a driven roller 6 , a belt support system 4 , an endless belt 7 , a filter cloth 8 , a vacuum box mechanism 3 and a feeder 2 . The bottom of one end of the frame 1 is provided with a feeding end frame 11, the other end is provided with a discharge end frame 12, one side of the discharge end frame 12 is provided with a discharge chute 9, and the inside of the feed end frame 11 is provided with a feed end frame bearing Support 14, the side of the feeding end frame 11 close to the middle frame 13 is provided with a feeding end frame reinforcement support 15, and the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com