Mechanical arm device with return and reversal function

A manipulator and functional technology, applied in the field of manipulators, can solve the problems of poor turning stability, poor reliability, traditional structure, etc., and achieve the effect of reliable clamping and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

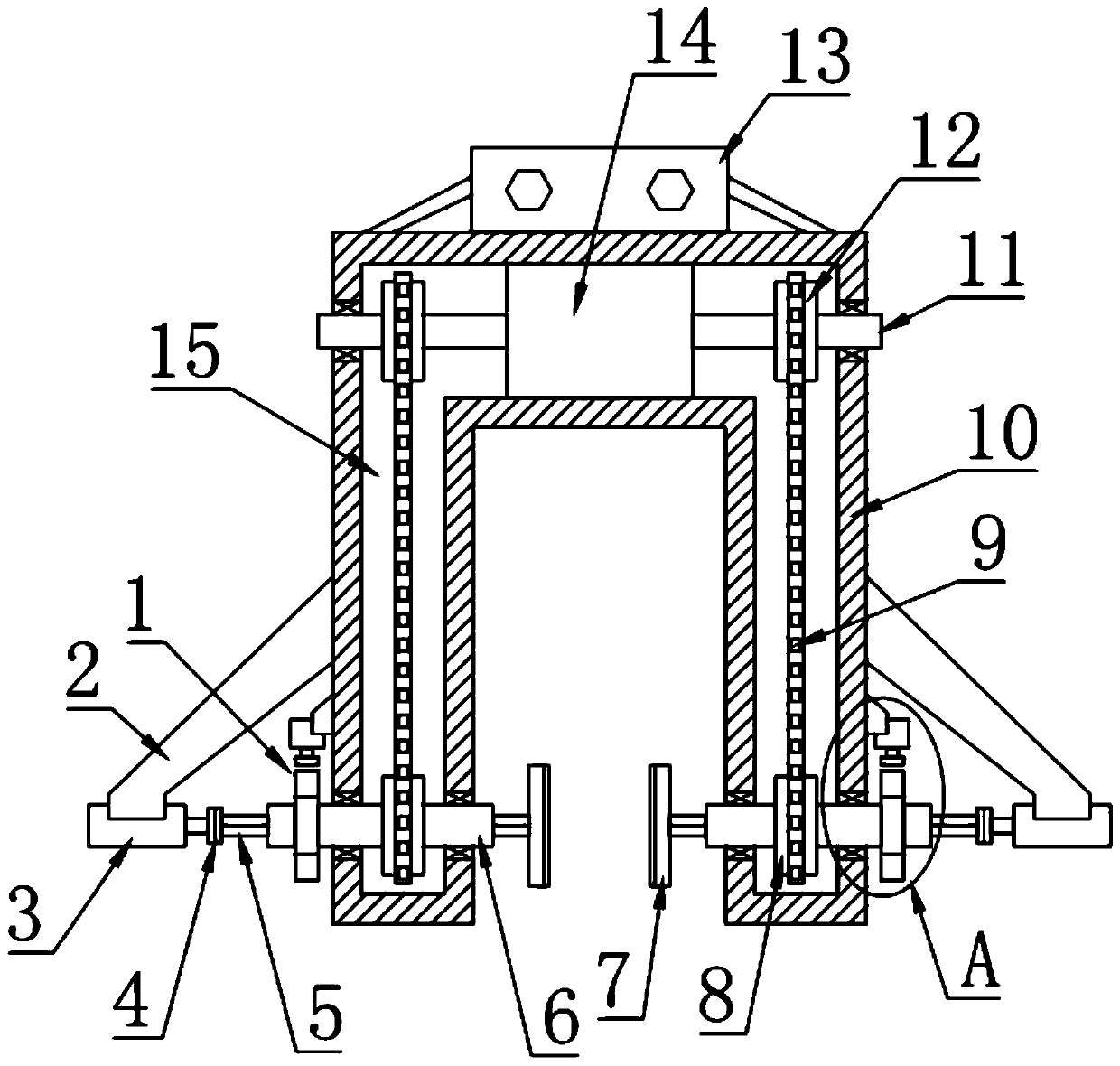

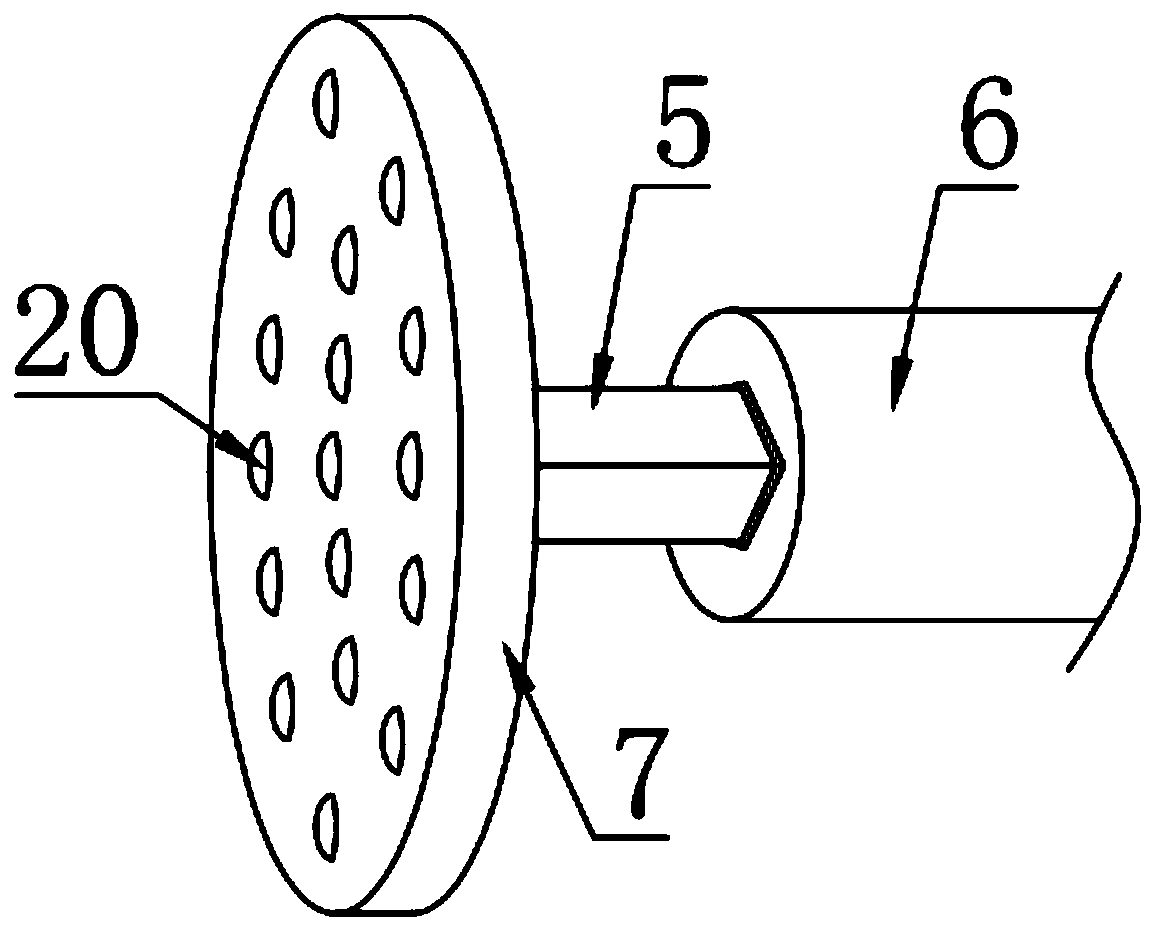

[0025] see Figure 1~4 , in the embodiment of the present invention, a manipulator device with the function of returning and turning includes a U-shaped housing 10, and a U-shaped cavity 15 is opened in the U-shaped housing 10, and a double The shaft extension motor 14 and the lower parts of both sides of the U-shaped cavity 15 are respectively equipped with sleeves 6. The biaxial extension motor 14 is connected with the two sleeves 6 through the transmission mechanism, and the biaxial extension motor 14 is used to drive the two sleeves at the same time. 6 rotates, the sleeve 6 is provided with a clamping rod 5 for sliding cooperation, the inner end of the clamping rod 5 is fixedly provided with a splint 7, and the outer end of the clamping rod 5 is connected with the clamping telescopic cylinder 3 through the rotating body 4, The clamping telescopic cylinder 3 is fixedly arranged on the outside of the U-shaped housing 10 through the first support frame 2 .

[0026] In this e...

Embodiment 2

[0031] see Figure 1~4 , the difference between this embodiment and embodiment 1 is:

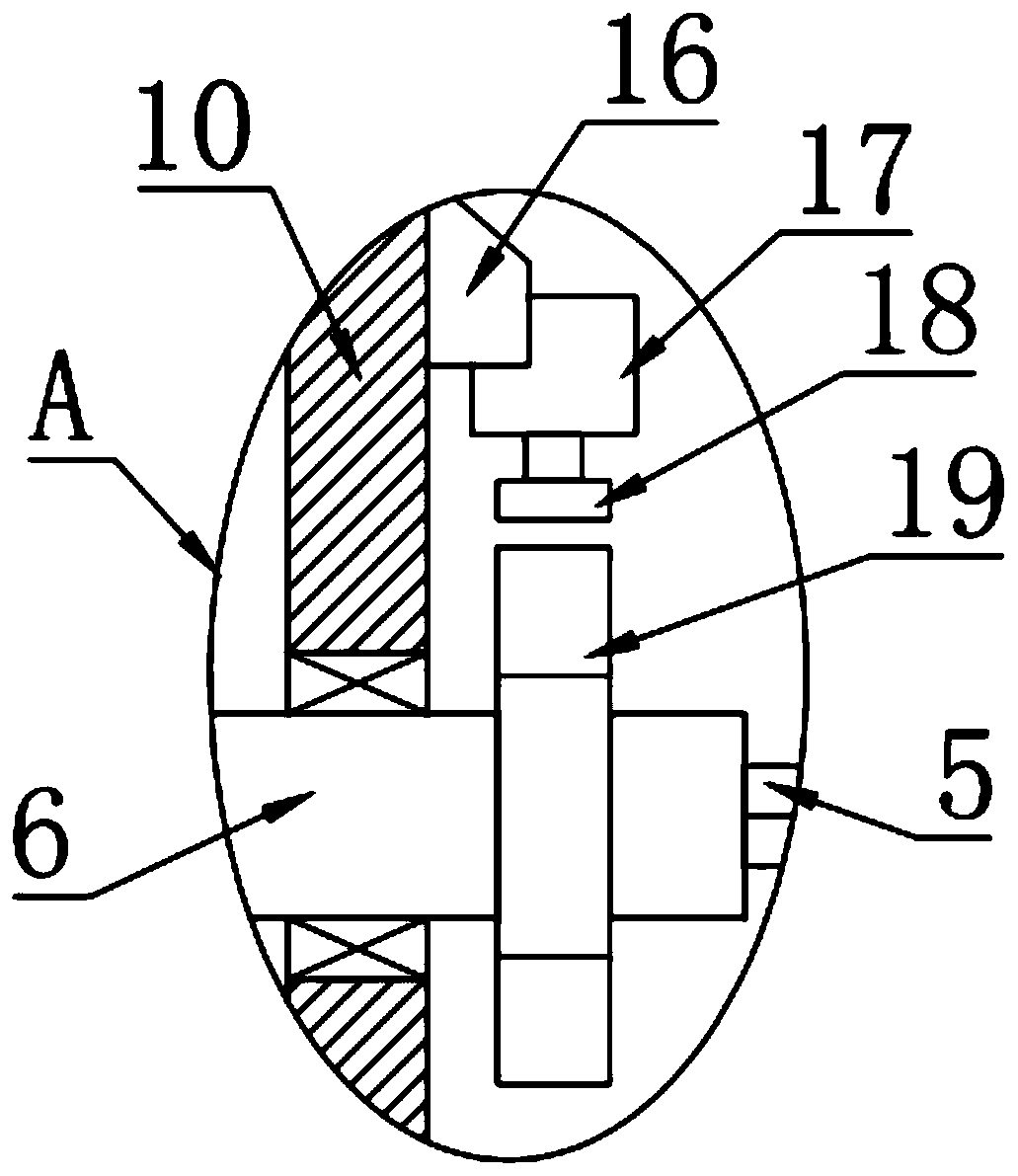

[0032] In this embodiment, the outside of the U-shaped housing 10 is also provided with a return brake assembly 1, and the return brake assembly 1 includes a second support frame 16, a brake telescopic cylinder 17, a brake block 18 and Brake ring plate 19, the brake ring plate 19 is a regular polygon structure, the brake ring plate 19 is provided with a through hole 21 matching with the sleeve 6, the brake ring plate 19 is sleeved and fixed on the sleeve 6 , and the brake ring plate 19 is fixedly connected with the sleeve 6, the brake ring plate 19 is provided with a brake telescopic cylinder 17, and the brake telescopic cylinder 17 passes through the second support frame 16 and the U-shaped shell The outer wall of the body 10 is connected and fixed, and the lower end of the piston rod of the brake telescopic cylinder 17 is equipped with a brake block 18 that can be closely matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com