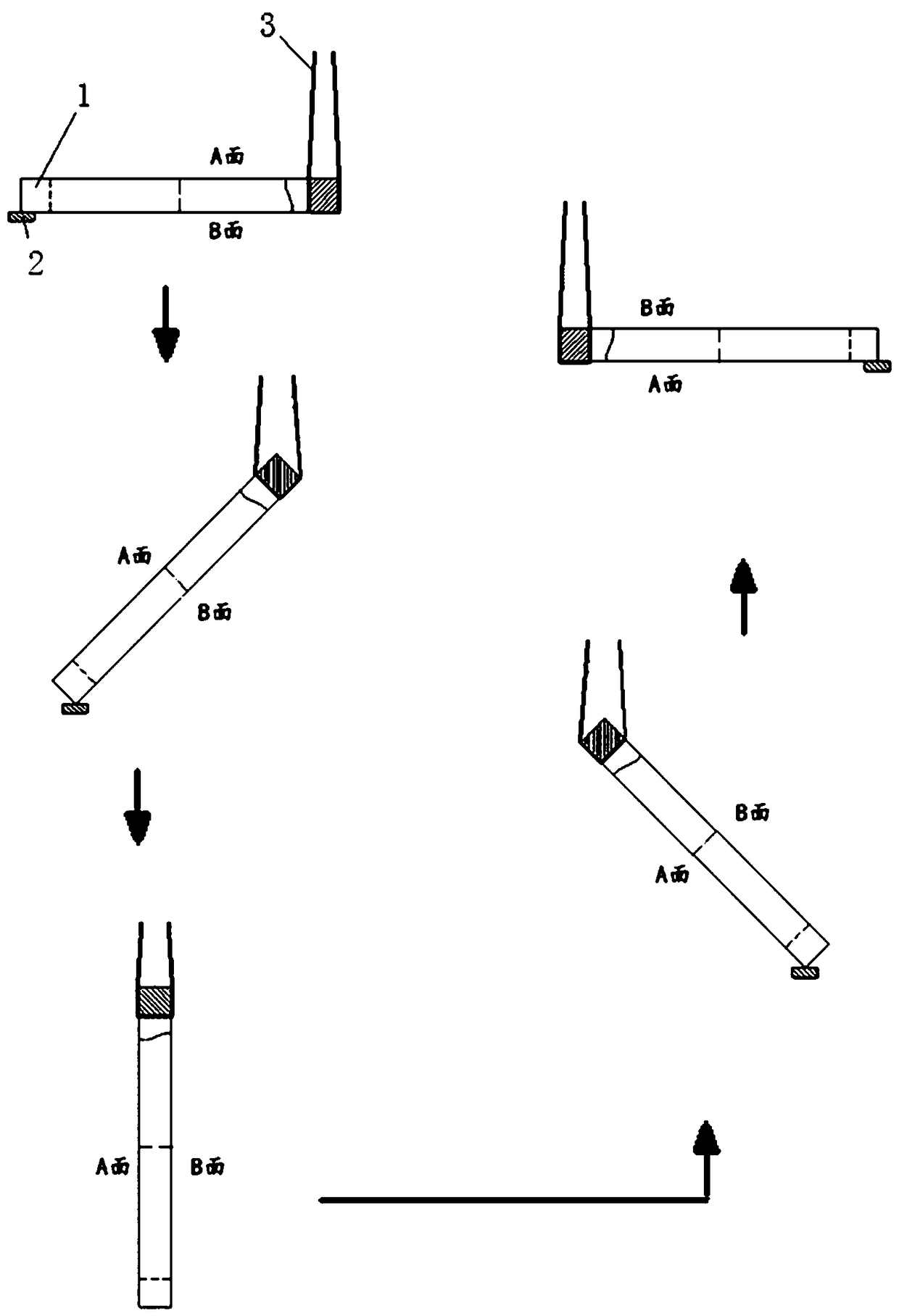

Overturning device and overturning method for large plate parts

A technology of flipping device and large plate, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of workpiece deformation, inability to realize, workpiece accuracy and quality risk, etc., and achieve the effect of ensuring product quality and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation of the large-scale plate parts turning device and turning method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] In order to make the present invention easy to understand, some directional terms are used in this specification. It should be noted that the directional terms mentioned in this specification, such as "up", "down", "left", "right", "front", "back", etc., refer to the directions of the drawings, and use The directional terms are used to illustrate and understand the present invention, but not to limit the protection scope of the present invention.

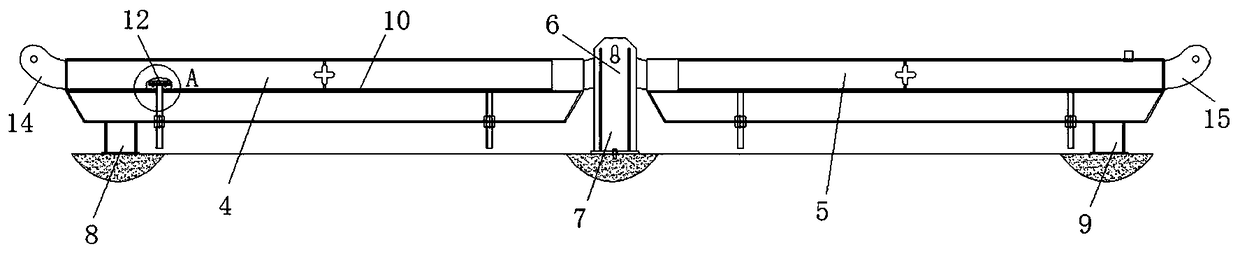

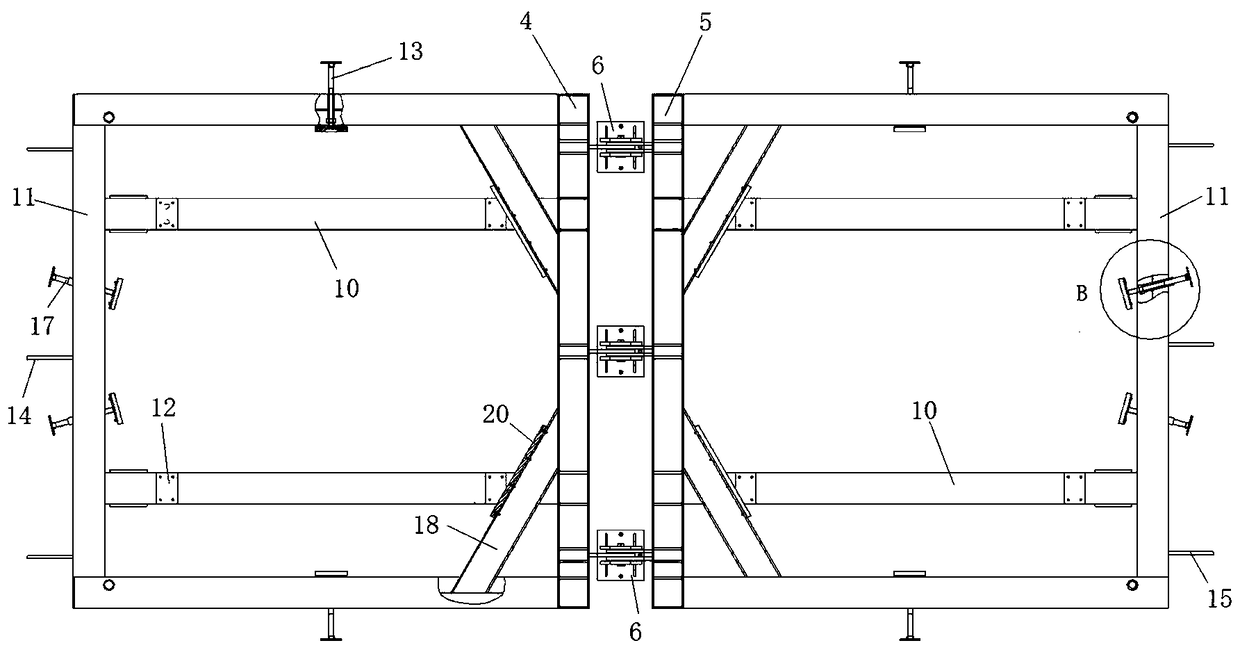

[0050] See attached figure 2 , 3 The overturning device for large plate parts includes a first rotating part 4 and a second rotating part 5. The two rotating parts have roughly the same structure and are arranged symmetrically.

[0051] The rotating shaft 6 is arranged on the supporting foot 7 of the rotating shaft, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com