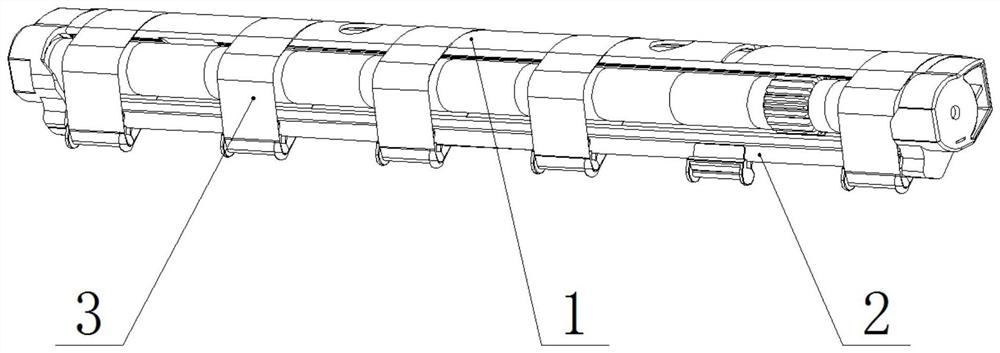

Compact spinning tension bracket overturning tool

A technology of frame turning and compact spinning, applied in spinning machine, textile and papermaking, drafting equipment, etc., to achieve the effect of easy turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

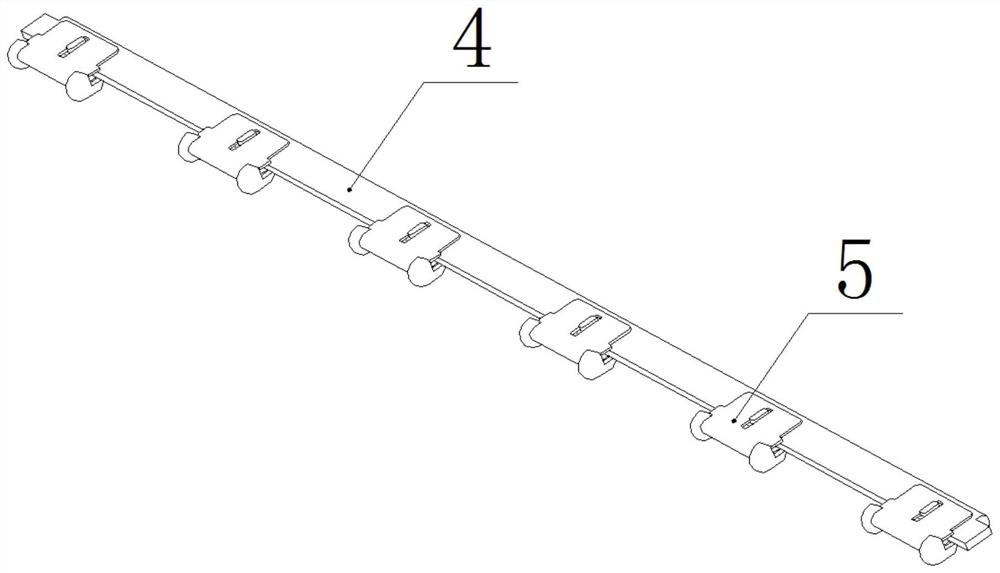

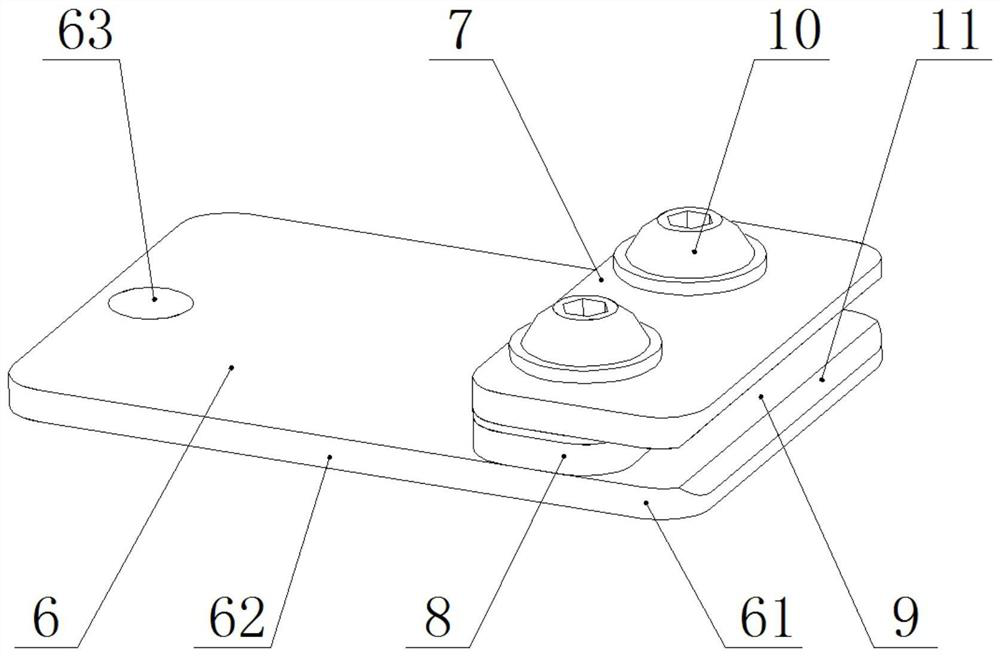

[0045] see Figure 3 ~ Figure 7 , a kind of compact spinning tension rack turnover tool that the present invention relates to, it comprises base plate 6, and described base plate 6 comprises front clamping part 61 and rear pinching part 62, and the position of described front clamping part 61 is provided with clamping plate 7. A backing plate 8 is provided between the front clamping portion 61 and the clamping plate 7, and the clamping plate 7 and the front clamping portion 61 form a clamping bayonet 9 at the front side of the backing plate 8;

[0046] The base plate 6, the clamping plate 7 and the backing plate 8 are connected by fasteners 10;

[0047] The height of the clamping bayonet 9 is greater than the thickness of the tension frame rod 4;

[0048] The front holding part 61 and the rear holding part 62 are integrally structured;

[0049] Both the front clamping part 61 and the rear clamping part 62 are planar plate structures;

[0050] The length of the rear gripping...

Embodiment 2

[0060] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the base plate 6 , the clamping plate 7 and the backing plate 8 are connected by welding or bonding.

Embodiment 3

[0062] Such as Figure 9 , Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the substrate 6 includes a front clamping portion 61 and a rear clamping portion 62, and there are multiple front clamping portions 61, and the multiple front clamping portions 61 are left and right Arranged side by side, a relief slot 64 is formed between two adjacent front clamping portions 61 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com