Double-circuit drive rotary lifting permanent magnet

A two-way drive, permanent magnet technology, applied in the direction of load hanging components, transportation and packaging, to achieve the effect of widening the scope of application, overcoming limitations, and stable and reliable turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

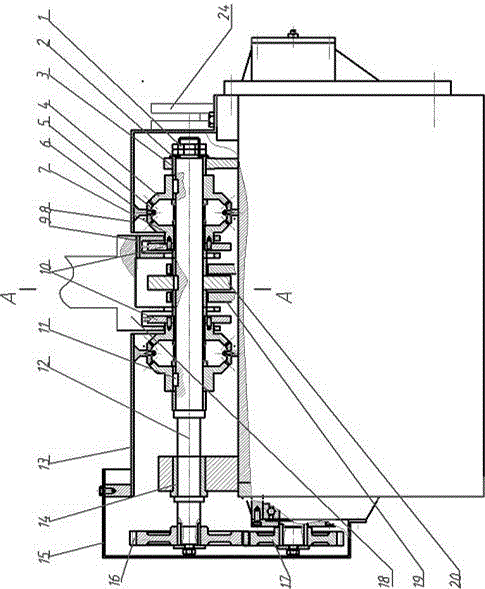

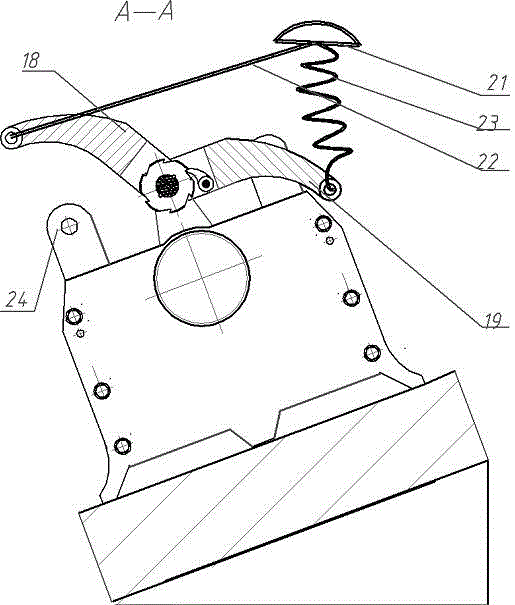

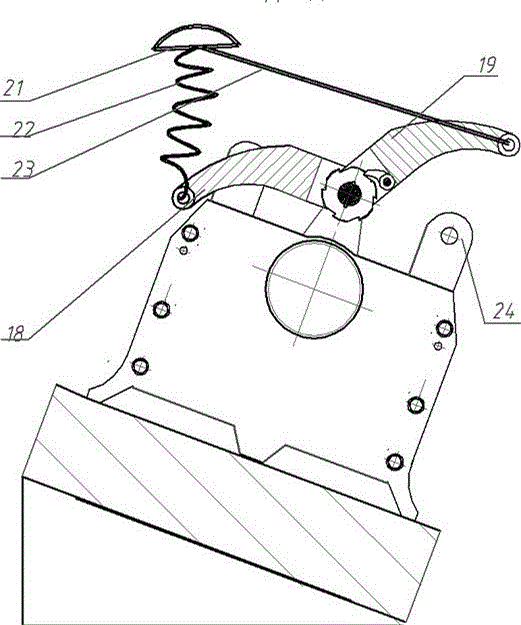

[0010] In order to make the two sets of drive mechanisms rotate the drive shaft in the same direction, the swing rod 19 in the front side ratchet swing rod drive mechanism is vacantly sleeved on the drive shaft 12, and the ratchet 20 is connected with the drive shaft 12 by a key. The ratchet 10 and the fork 18 of the rear side ratchet fork drive mechanism are all sleeved on the drive shaft 12 by sliding bearings, and can be relatively rotated with the drive shaft. The fork 18 and the fork 19 rotate in opposite directions during the process of lifting the object to be sucked. The ratchet 10 is fixed together with the conical disc gear 7, the conical disc gear 7 meshes with the bevel gear 5 supported by the positioning frame 6, the bevel gear 5 meshes with the conical hub gear 4, and the conical hub gear 4 is connected to the drive shaft through the key 11 12 connections. In this way, the rear ratchet swing bar drive mechanism and the front ratchet swing bar drive mechanism can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com