Wheel-type automatic turnover equipment with hydraulically-driven clamping mechanism

A clamping mechanism and automatic inversion technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of danger, difficulty in popularization, and increase the cost of goods transportation, and achieve the effect of safe inversion process, improved inversion efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

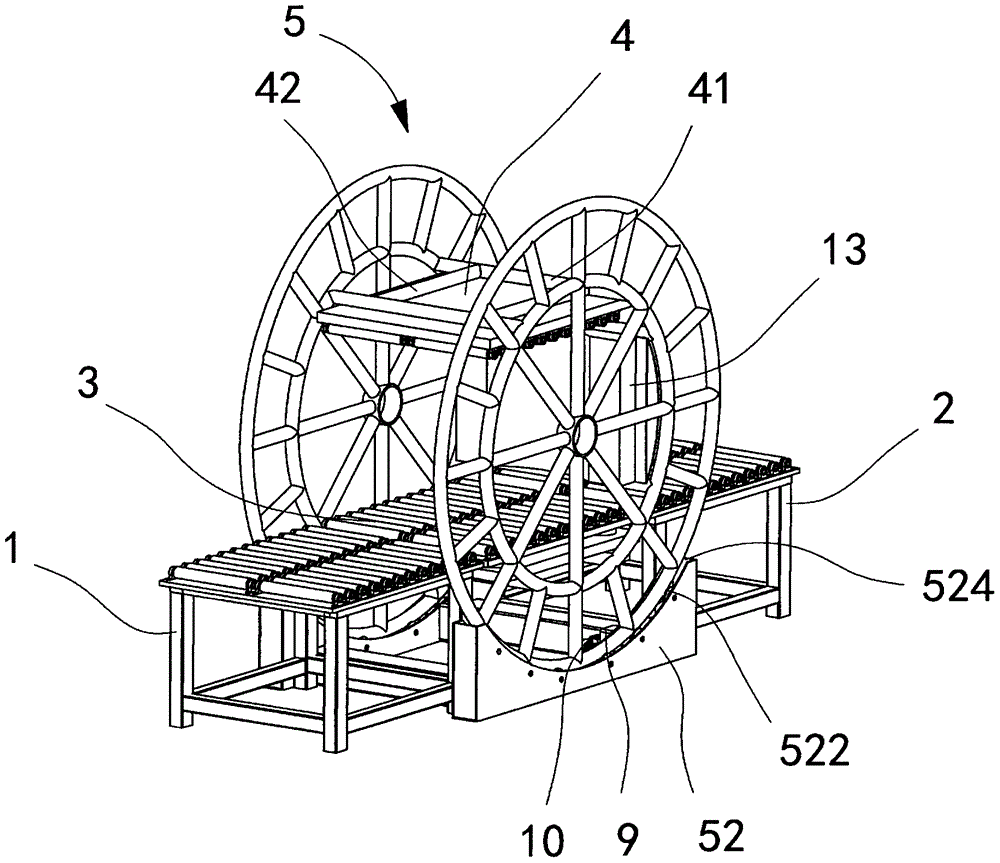

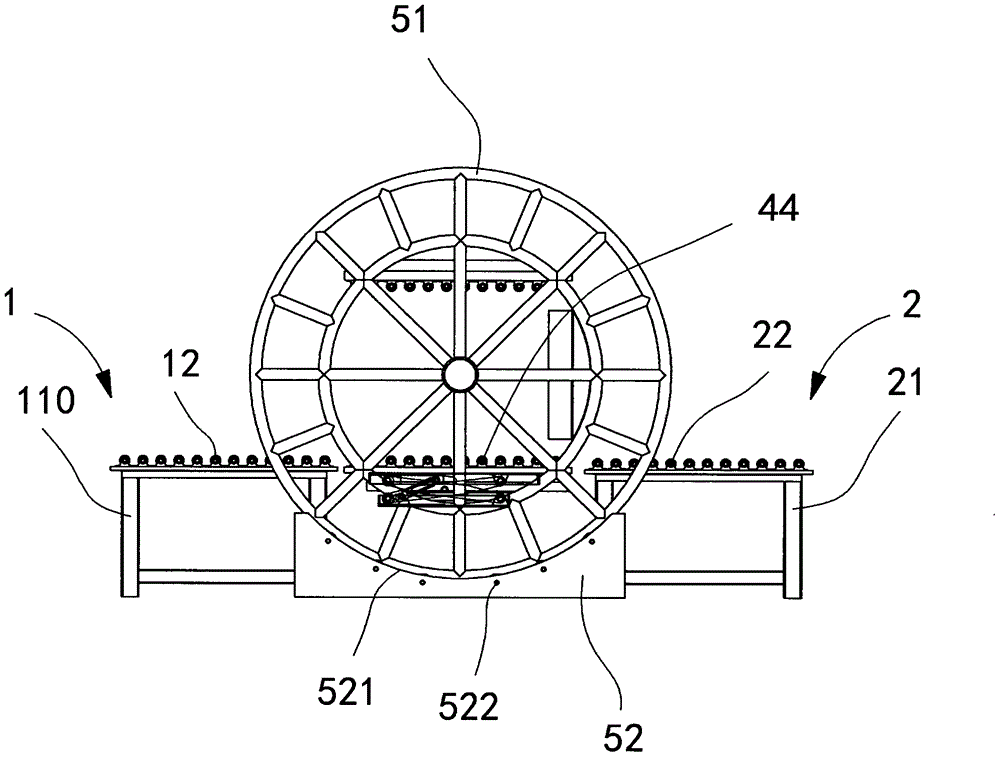

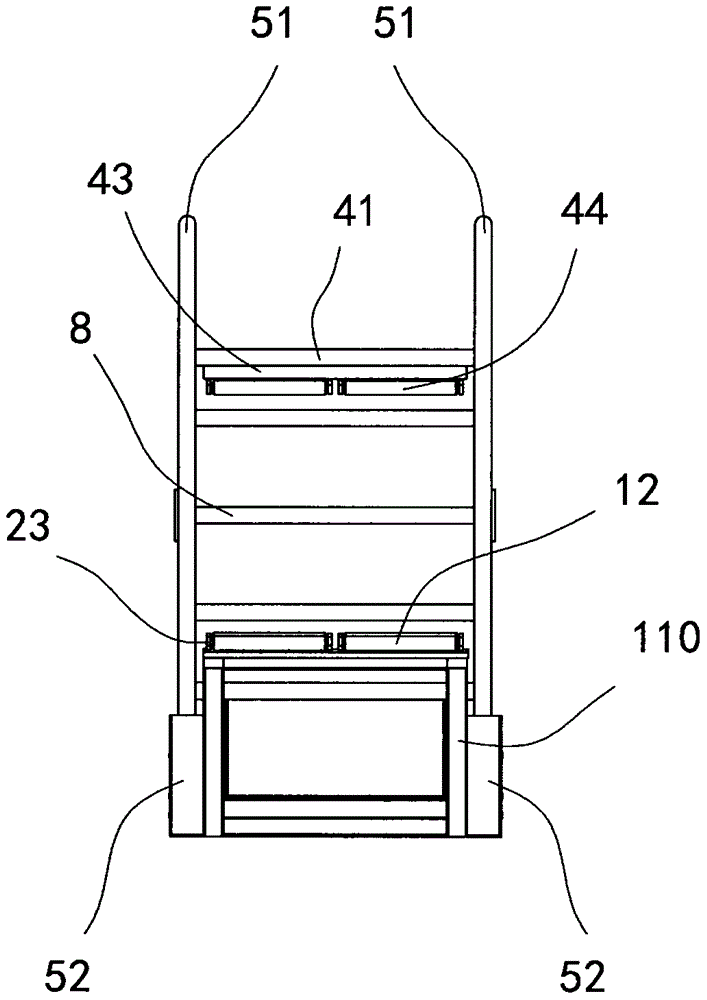

[0018] Such as Figures 1 to 8 Shown is an embodiment of a wheel-type automatic turning device whose clamping mechanism is driven by hydraulic pressure in the present invention. In this embodiment, the automatic turning device includes an inlet conveying mechanism 1 and an outlet conveying mechanism 2, and the inlet conveying mechanism 1 and the outlet convey A turning mechanism 5 is arranged between the mechanisms 2, and a first intermediate conveying mechanism 3 and a second intermediate conveying mechanism 4 are arranged on the turning mechanism 5, and the first intermediate conveying mechanism 3 and the second intermediate conveying mechanism 4 are arranged on the turning mechanism in parallel. 5, a lifting mechanism 11 is provided below the first intermediate conveying mechanism 3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com