Automatic car door cover conveying and feeding equipment and feeding method

An automatic conveying and door cover technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of shortening the movement distance of operators, labor intensity of workers, unstable pressing and feeding methods, and poor automation , to avoid safety and quality risks, convenient and fast switching, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

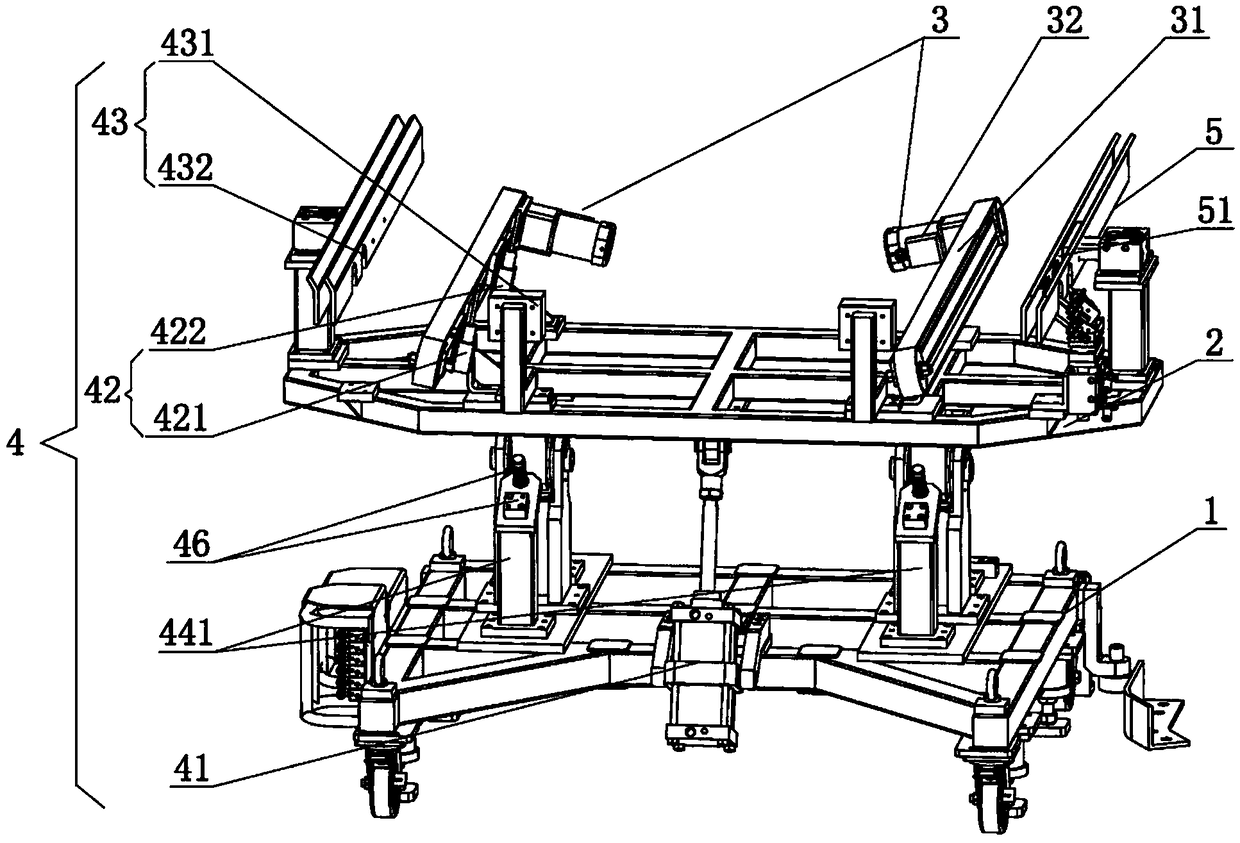

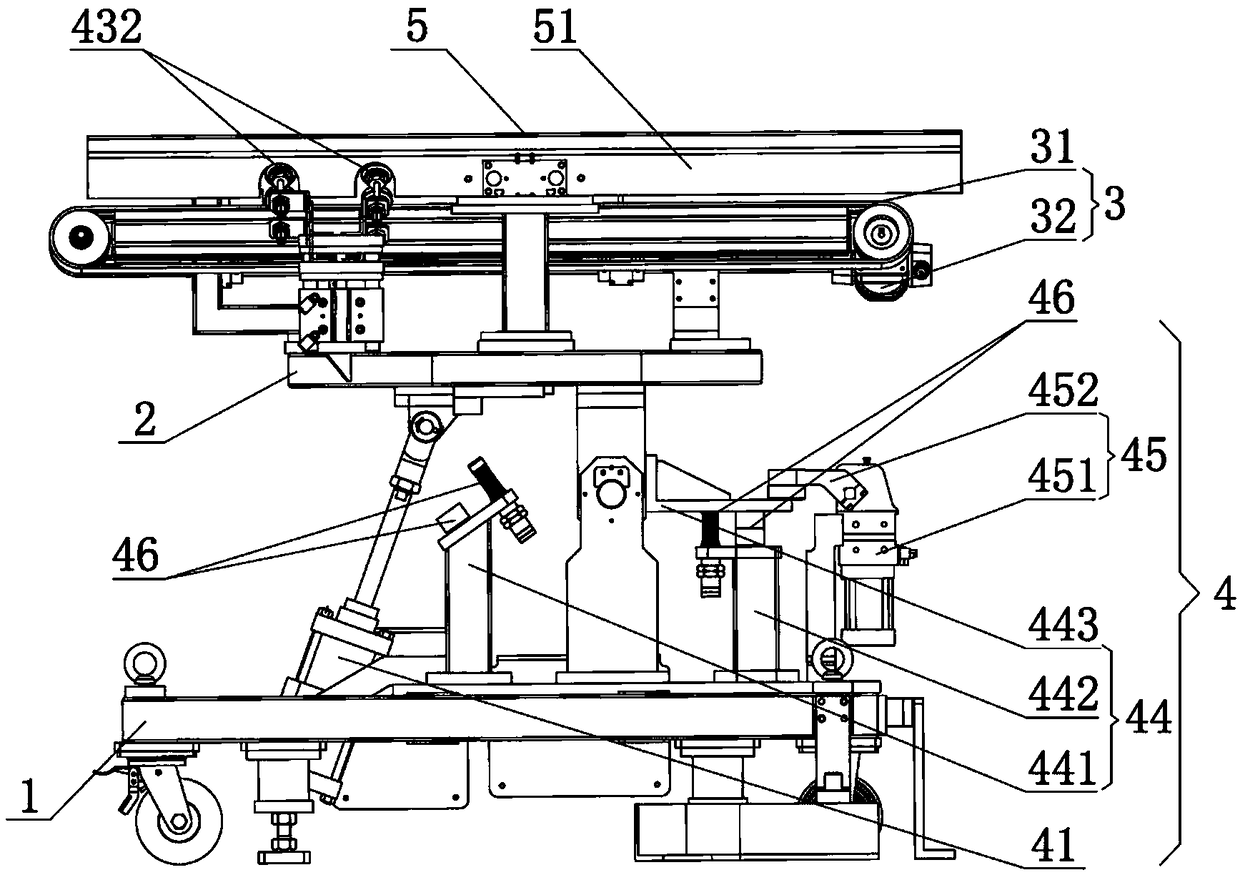

[0029] Concrete embodiment of the present invention is: as figure 1 , figure 2 As shown, a kind of automatic conveying and feeding equipment for automobile door covers includes a hingedly connected underframe 1 and a support frame 2, a conveying mechanism 3 fixed on the support frame 2, and a turning mechanism 4 that automatically turns and resets the support frame 2. The mechanism 4 includes an execution unit 41 that drives the support frame 2 to turn over, a detection unit 42 that detects the position of the car door cover, and a control unit that receives the signal from the detection unit 42 and drives the execution unit 41 to act. This control unit can be coordinated and controlled by PLC and electrical components.

[0030] Specifically, the conveying mechanism 3 includes a conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com