Slider Turner

A technology of turning machines and sliders, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of easily damaged sliders, low work efficiency, and unsafety, so as to eliminate potential safety hazards and improve work efficiency , Flip safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

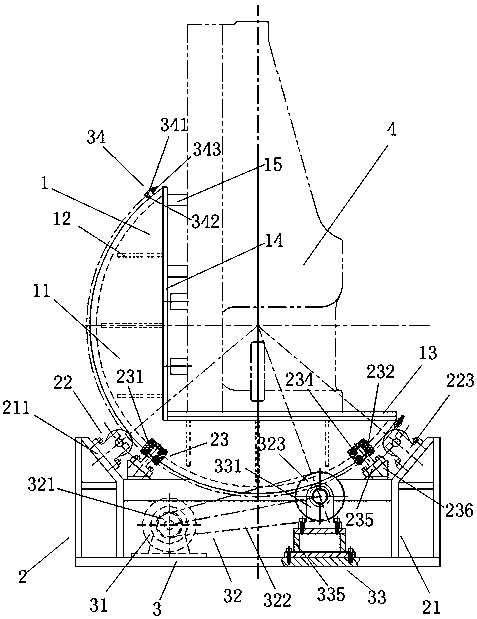

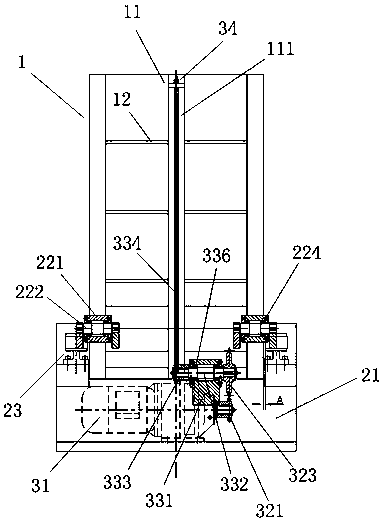

[0015] Such as figure 1 and figure 2 As shown, the present invention includes a slider support frame 1, a support device 2 and a support frame overturn driving device 3, the slider support frame 1 is supported on the support device 2, and the support frame overturn drive device 3 is arranged on the outside of the slider support frame 1 and supporting device 2.

[0016] The end face of the slider support frame 1 is a structural part with a right-angled inner side and an arc-shaped outer side. In this embodiment, it is a welded structural part, or it can be a casting. Slider support frame 1 comprises 3 vertical plates 11, a plurality of rib plates 12 and two support plates A13 and a support plate B14 constituting the square surface. Fixed connection into one. The bottom surface of the press slide block 4 abuts against the supporting plate A13 of the right-angled bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com