Overturning and lifting method for major-diameter superheavy end socket

A hoisting method and large-diameter technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of overturning of overturned objects, local stress of lifting lugs, large overall deflection, overloading of machine rigging, etc., to achieve a stable turning process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

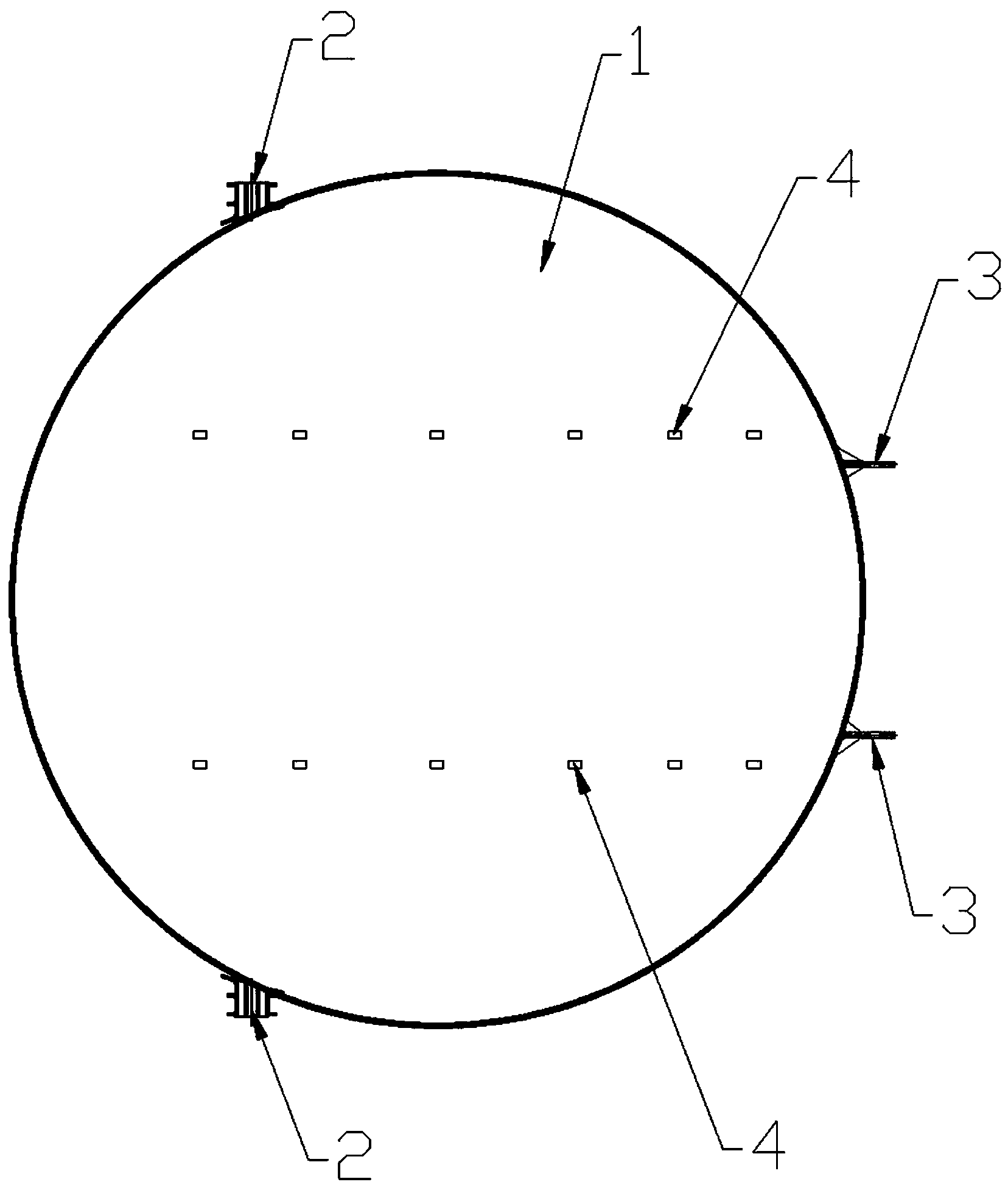

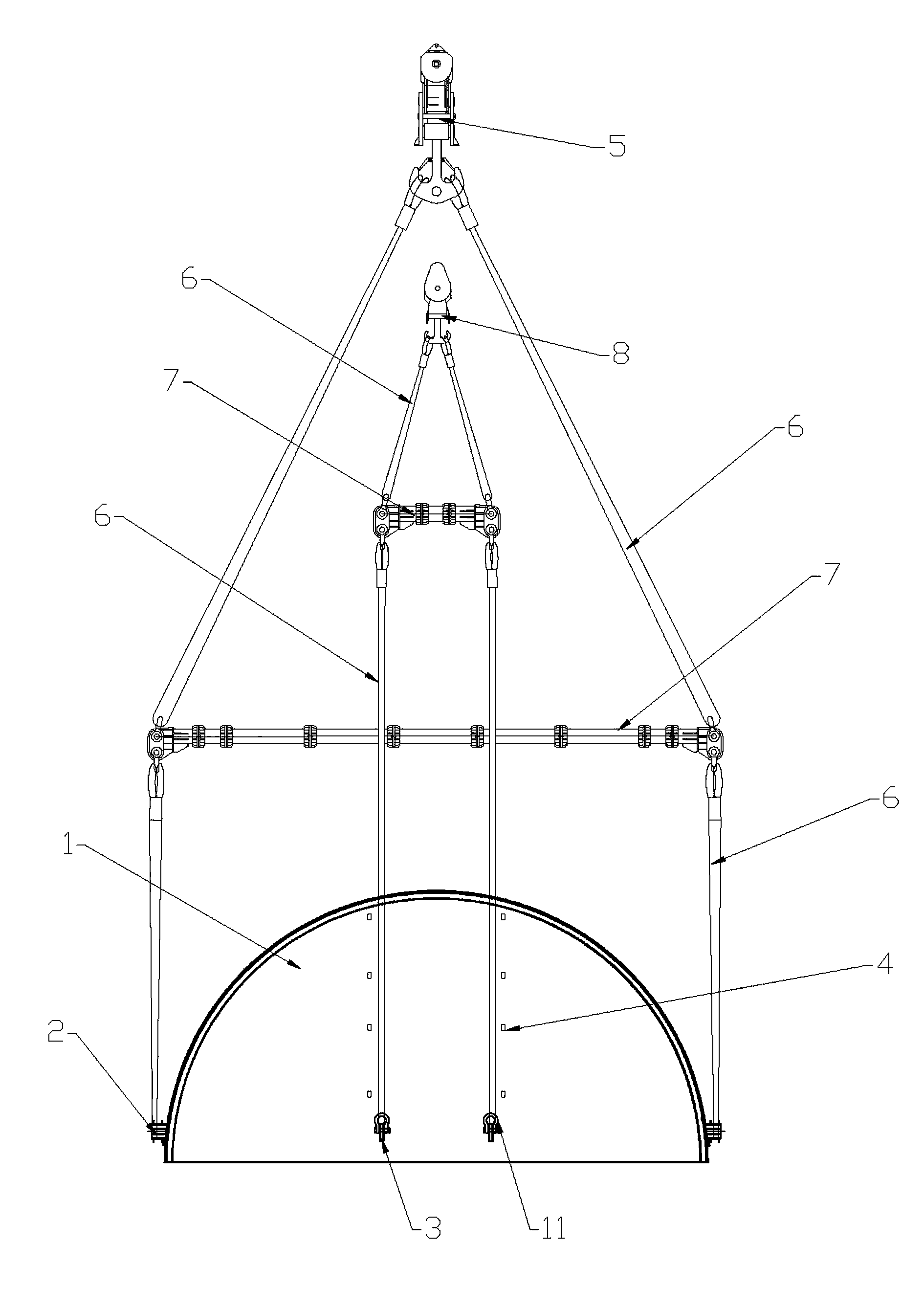

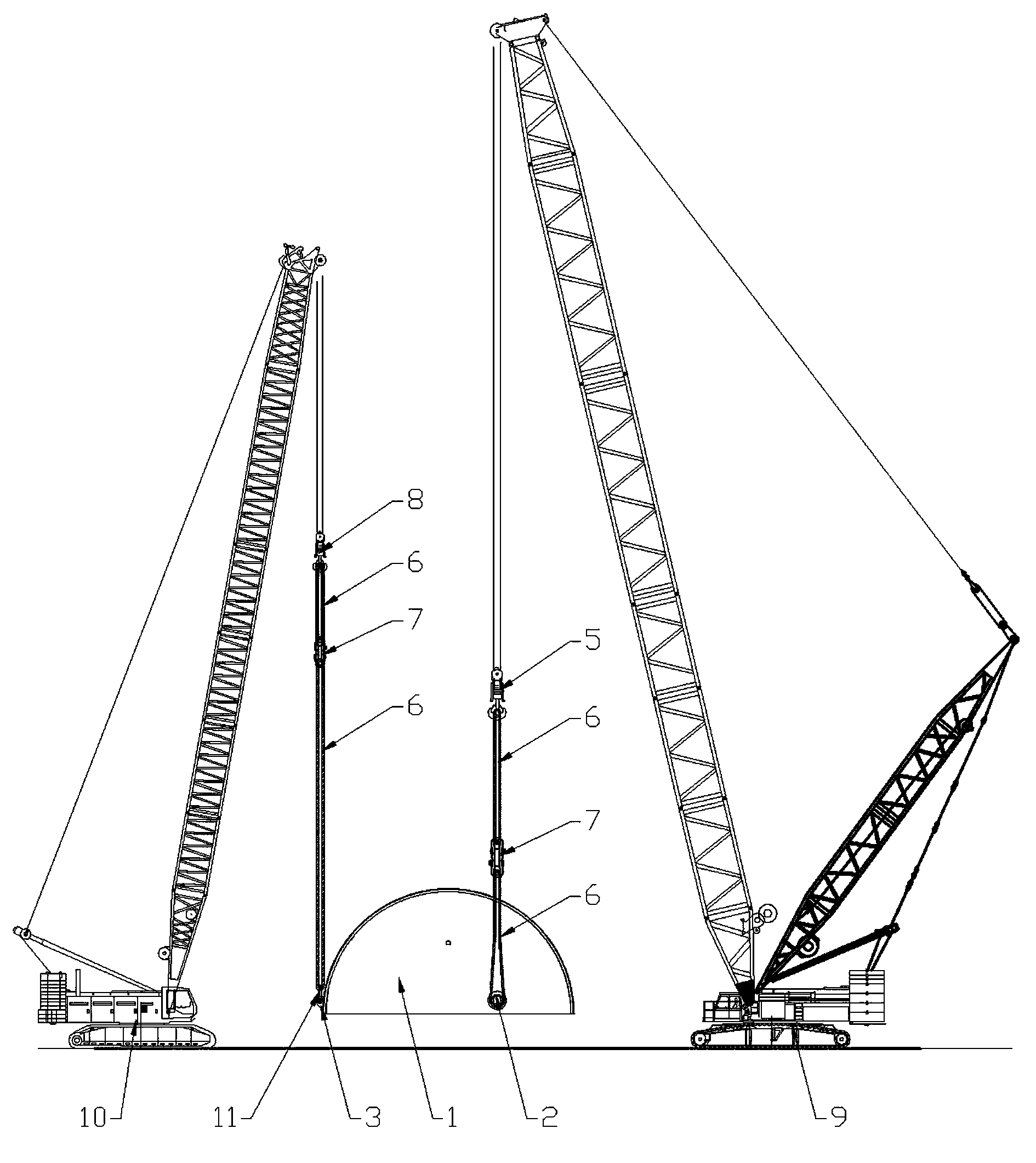

[0030] Select a large-diameter super-heavy head 1 with a circle formed by the lower edge of the head with a diameter of 16 m for flipping and hoisting, as shown in Figure 3-6shown. Firstly, two main lifting lugs 2 and two tail lifting lugs 3 are respectively provided on the outer wall of the head 1, wherein the connecting axis of the two main lifting lugs 2 is sag to the circle formed by the lower edge of the head 1. The vertical distance between the lines is 0.48m~0.96%Dm, the vertical distance from the center of each main lifting lug 2 to the lower edge of the head 1 is 0.56m~1.04m, and the distance between the centers of two sliding tail lifting lugs 3 The distance between the center of each sliding tail lug 2 and the lower edge of the head 1 is 1.04m to 1.68m; then the main crane 9 and the auxiliary crane 10 are respectively set on the On both sides of the head 1, the main crane hook 5 on the main crane 9 is connected to the upper part of the balance beam 7 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com