Two-jaw self-centering adjustable chuck

A self-centering and chucking technology, applied in the direction of chucking, etc., can solve the problems of three-jaw chuck or four-jaw chuck with complex structure, cumbersome methods, inaccuracy, etc., and achieve simple structure, convenient use, and large height range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

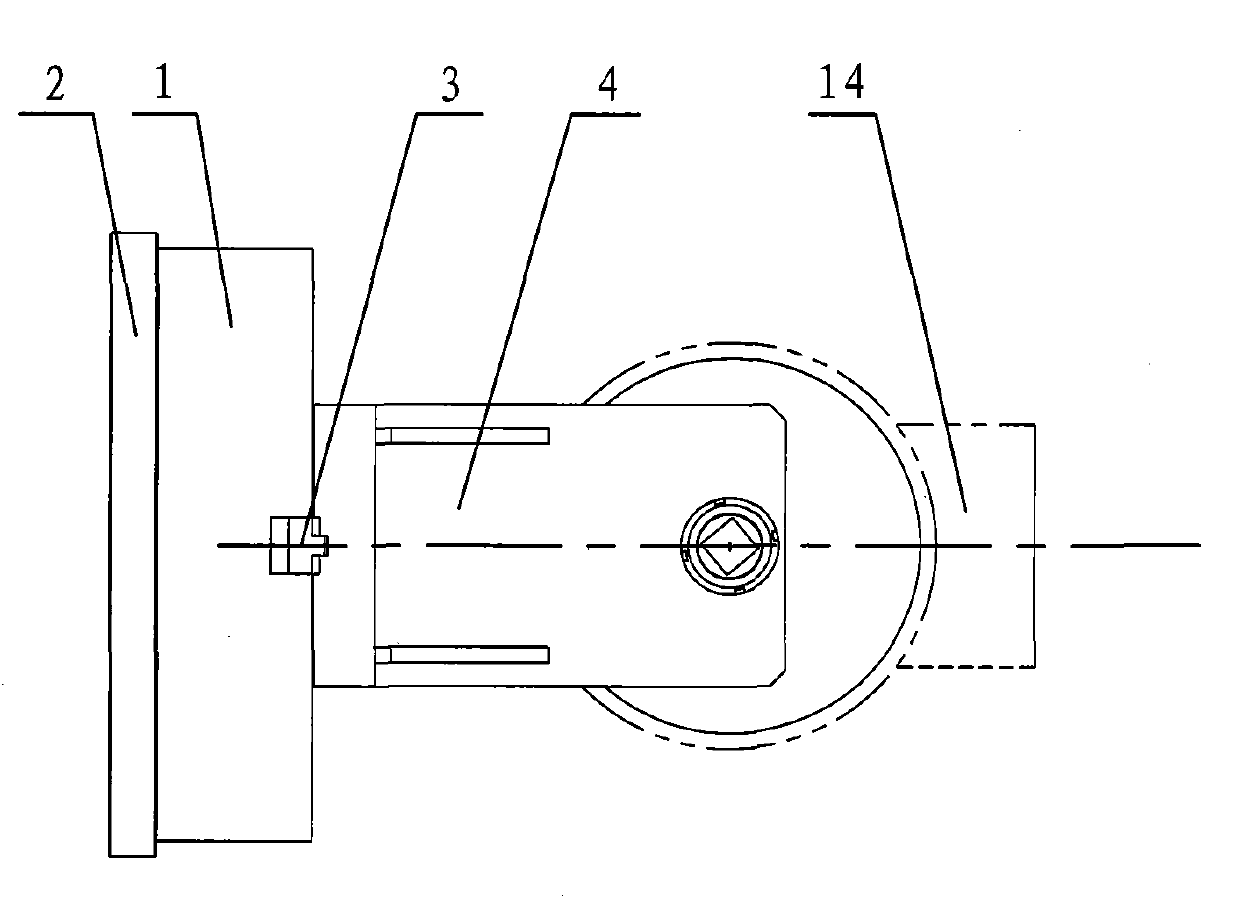

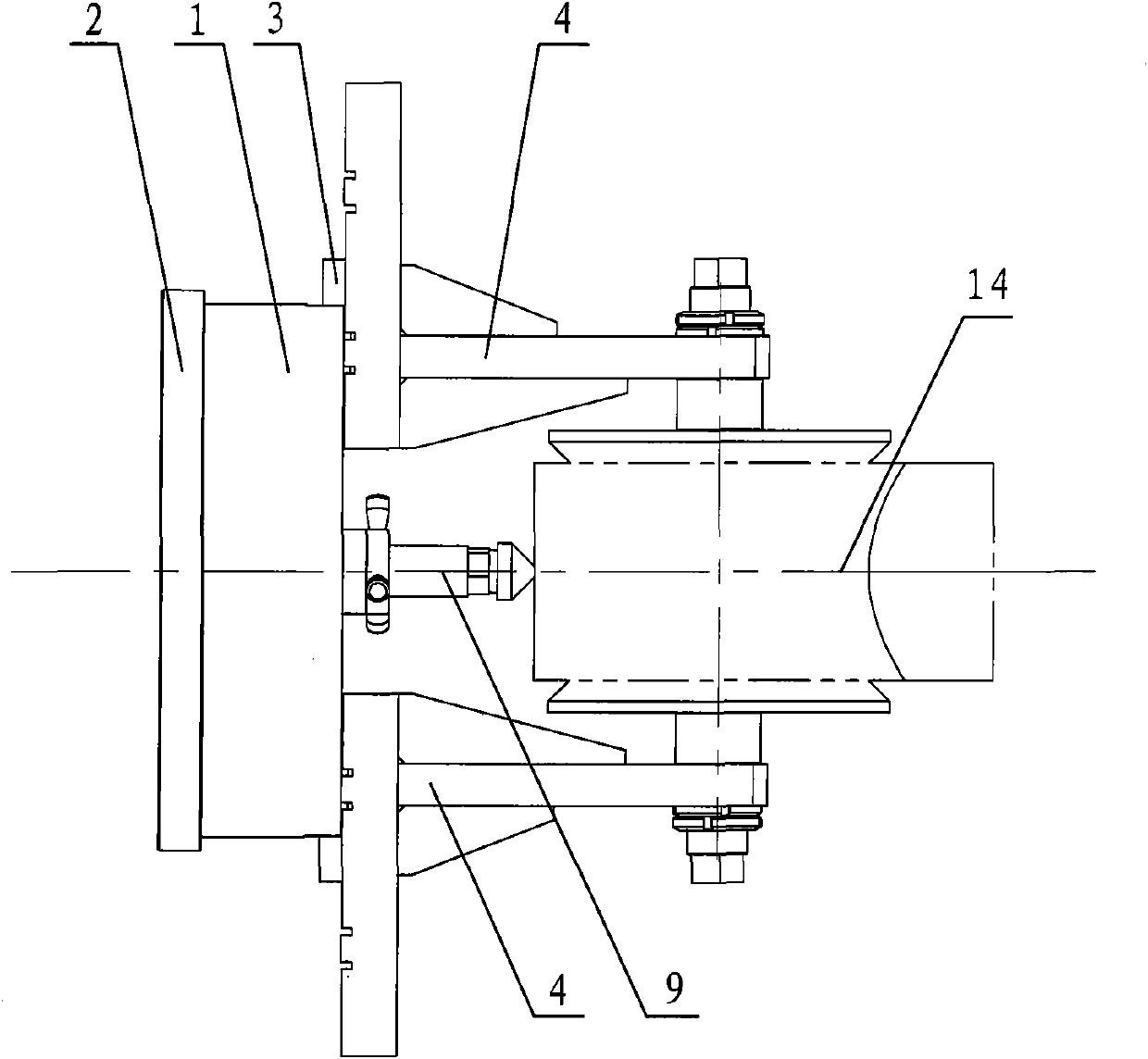

[0025] See attached figure 1 And figure 2 Shown.

[0026] A two-jaw self-centering adjustable chuck, comprising a chuck body 1, an adapter plate 2 connecting the chuck body 1 and a machine tool. The chuck body 1 is provided with a jaw connecting plate 3 and a jaw connecting plate 3 A pair of adjustable jaws 4 located on a diameter on the chuck body 1 are connected to the chuck body 1, and an adjustable center 9 is connected to the adapter plate 2 by bolts.

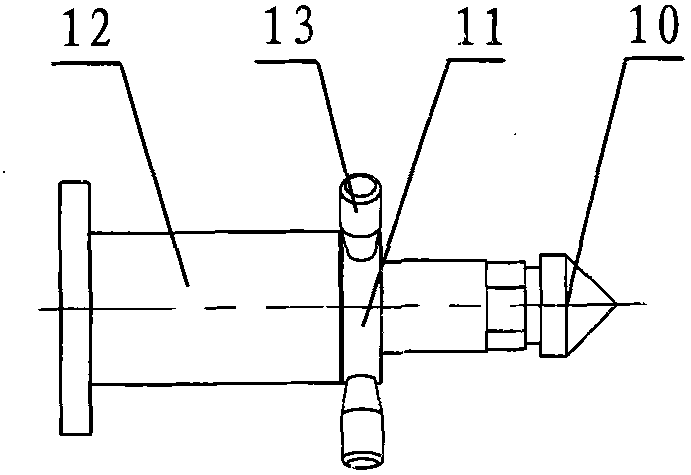

[0027] See attached image 3 And Figure 4 Shown.

[0028] The adjustable jaw 4 includes a thimble 5, a connecting rod 6 vertically connected to the thimble 5, an "L"-shaped jaw bracket 7 matching the jaw connecting plate 3, and fixing the connecting rod 6 on the jaw bracket 7 The nut 8. The first end of the "L"-shaped claw bracket 7 is connected to the claw connecting plate 3, and the connecting rod 6 is fixedly connected to the second end. The thimble 5 has two states relative to the claw bracket 7. The thimble 5 can be fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com