Measuring tape finial mechanism and measuring tape thereof

A top-notch, tape measure technology, applied in the direction of bendable rulers, etc., can solve the problems of potential safety hazards, accidental injury to the human body, unfavorable packaging and transportation, etc., and achieve the effect of simple and reasonable overall structure and convenient setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

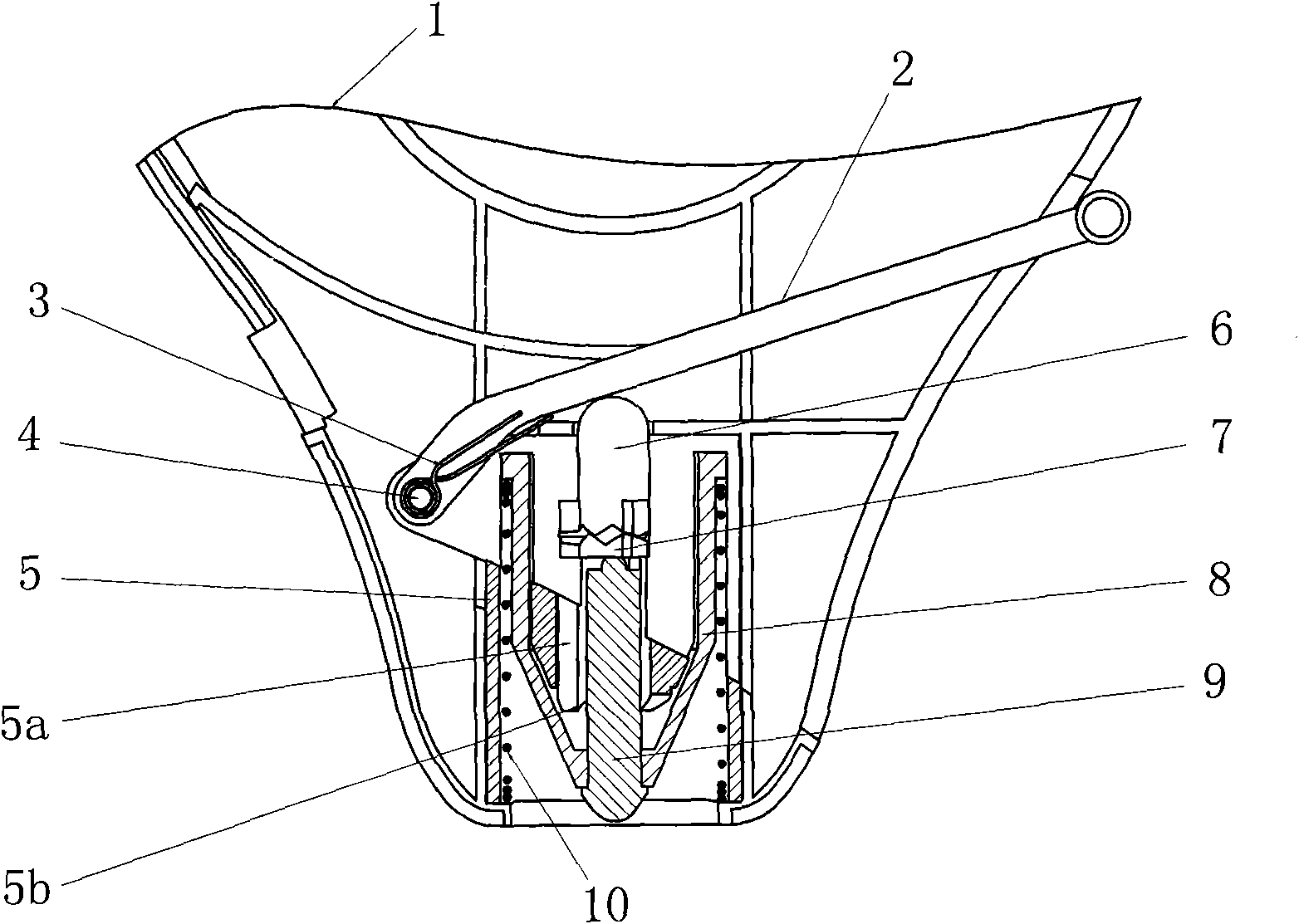

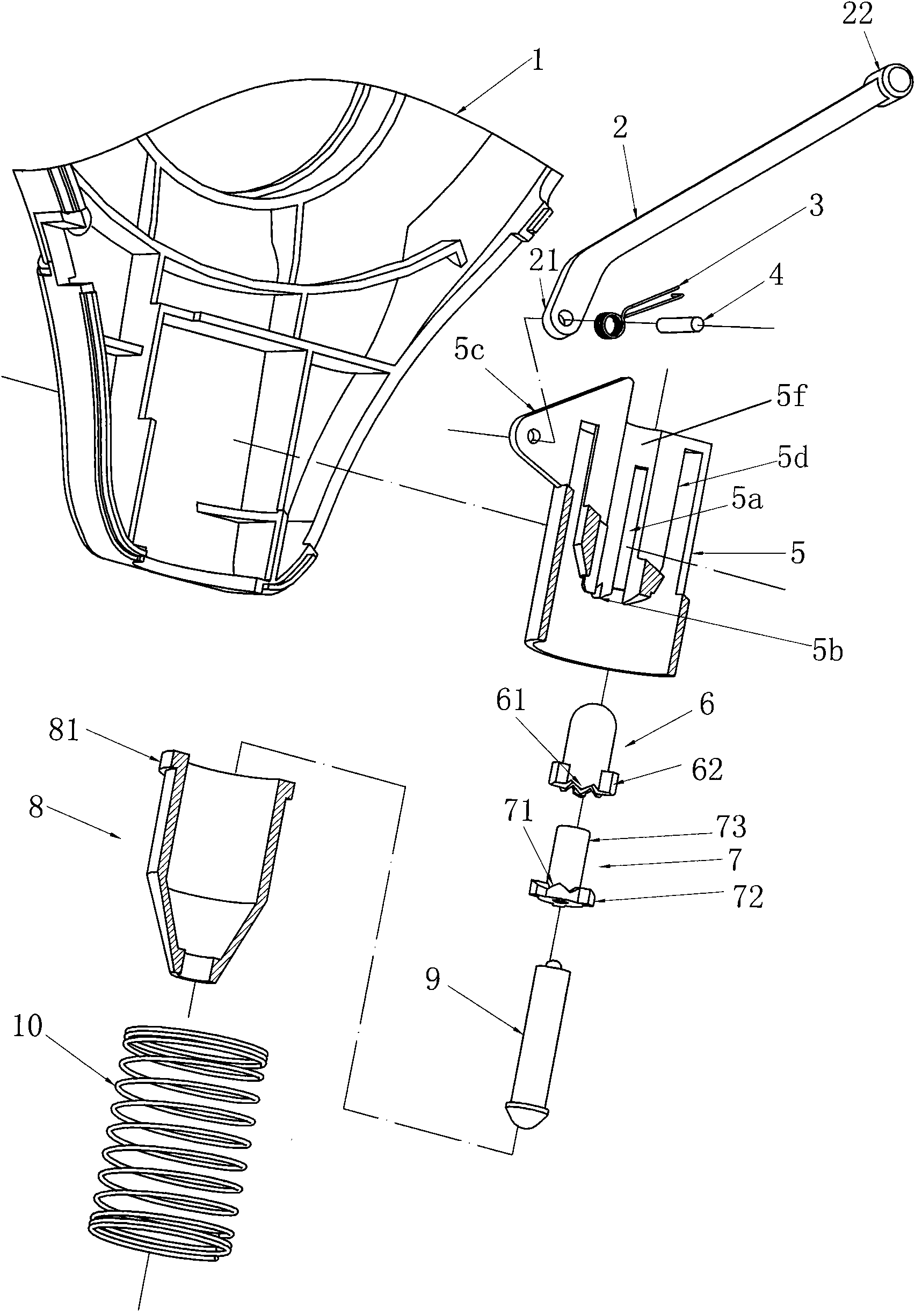

[0049] Example 1: Reference figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a tape measure with a tip mechanism includes a scale case 100 , a casing 5 , an upper pusher 6 , a lower pusher 7 , a drive mechanism, a tip seat 8 , a reset member 10 and a tip 9 .

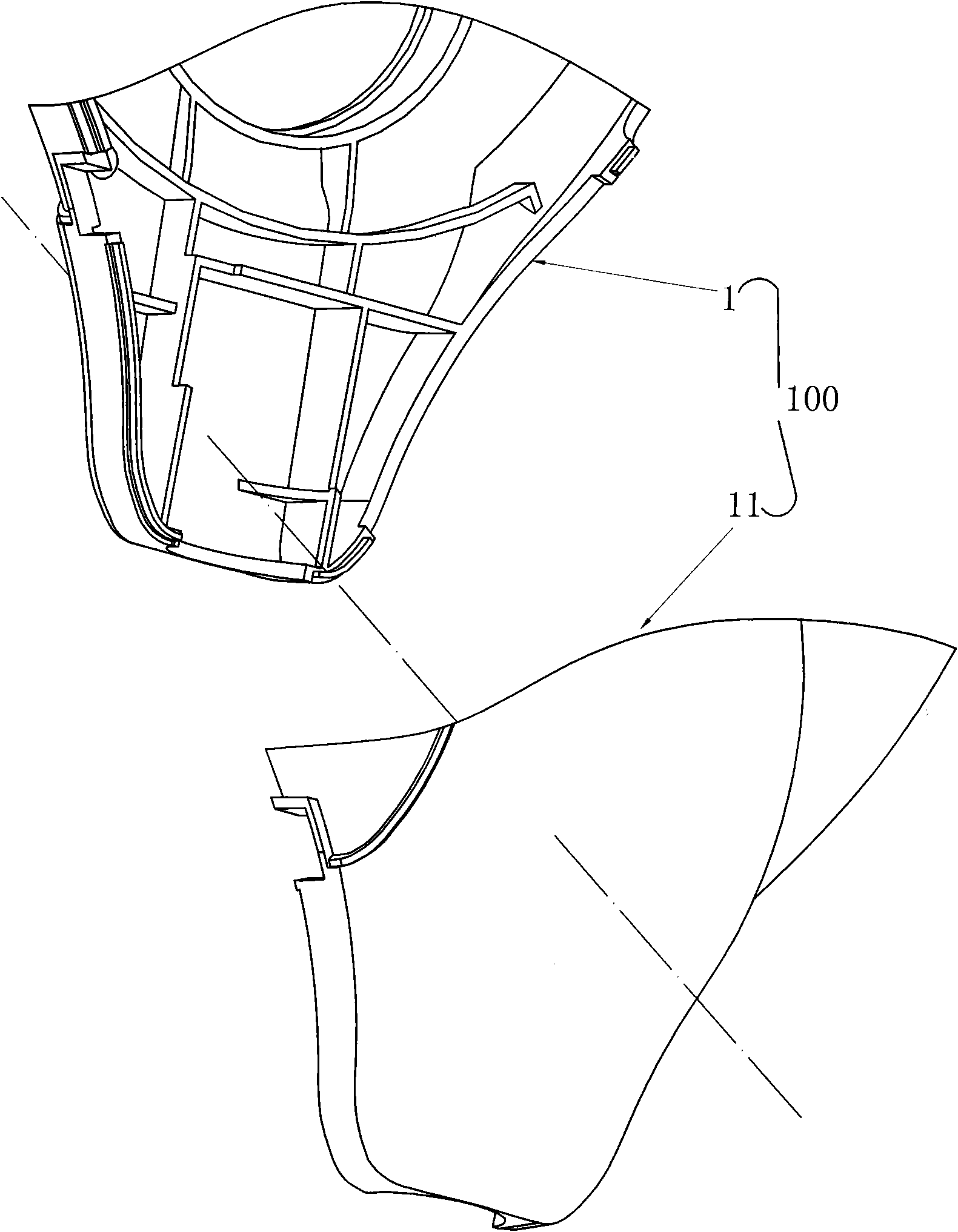

[0050] refer to image 3 As shown, the scale housing 100 is assembled from the regular scale housing 1 and the reverse scale housing 11, with a cavity in the middle for the top mechanism to accommodate, and a lip at the mouth.

[0051] The outer casing 5 is arranged in the scale housing 100, and has a raised cylinder 5d in the center. The center of the cylindrical 5d has a through hole 5f that runs through the outer casing 5. There is an axial slide rail 5a in the through hole 5f, and the lower end of the cylindrical 5d surrounds the through hole. A serrated first helical tooth 5b is formed. There is a pair of lugs 5c extending from the upper end of the outer casing 5, and a pivot pin 4 is arranged between t...

Embodiment 2

[0060] Embodiment 2, refer to Figure 7 As shown, the driving mechanism in the tape measure with the top mechanism in this embodiment includes a button 2, the button 2 is limited to the upper part of the outer cover, the lower end of the button 2 is in conflict with the upper end of the upper push piece, and a force button is arranged between the button and the outer cover. Reverse force reset elastic member 3a. In this embodiment, the return elastic member 3 a is a compression spring, and one end of the compression spring abuts against the button 2 , and the other end of the compression spring abuts against the inner wall of the casing 100 . Other structures are the same as in Embodiment 1.

Embodiment 3

[0061] Embodiment 3, refer to Figure 8 As shown, the driving mechanism in the tape measure with the top mechanism in this embodiment includes a horizontal pressing rod 2 limited in the scale housing and a return elastic member 3a that forces the pressing rod to be reversed. The middle part of the pressing rod 2 is connected to the The upper ends of the push-up parts are offset, and the other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com