Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

A processing method and machine tool technology, applied in the direction of metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving the utilization rate, reducing the production cost, and increasing the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

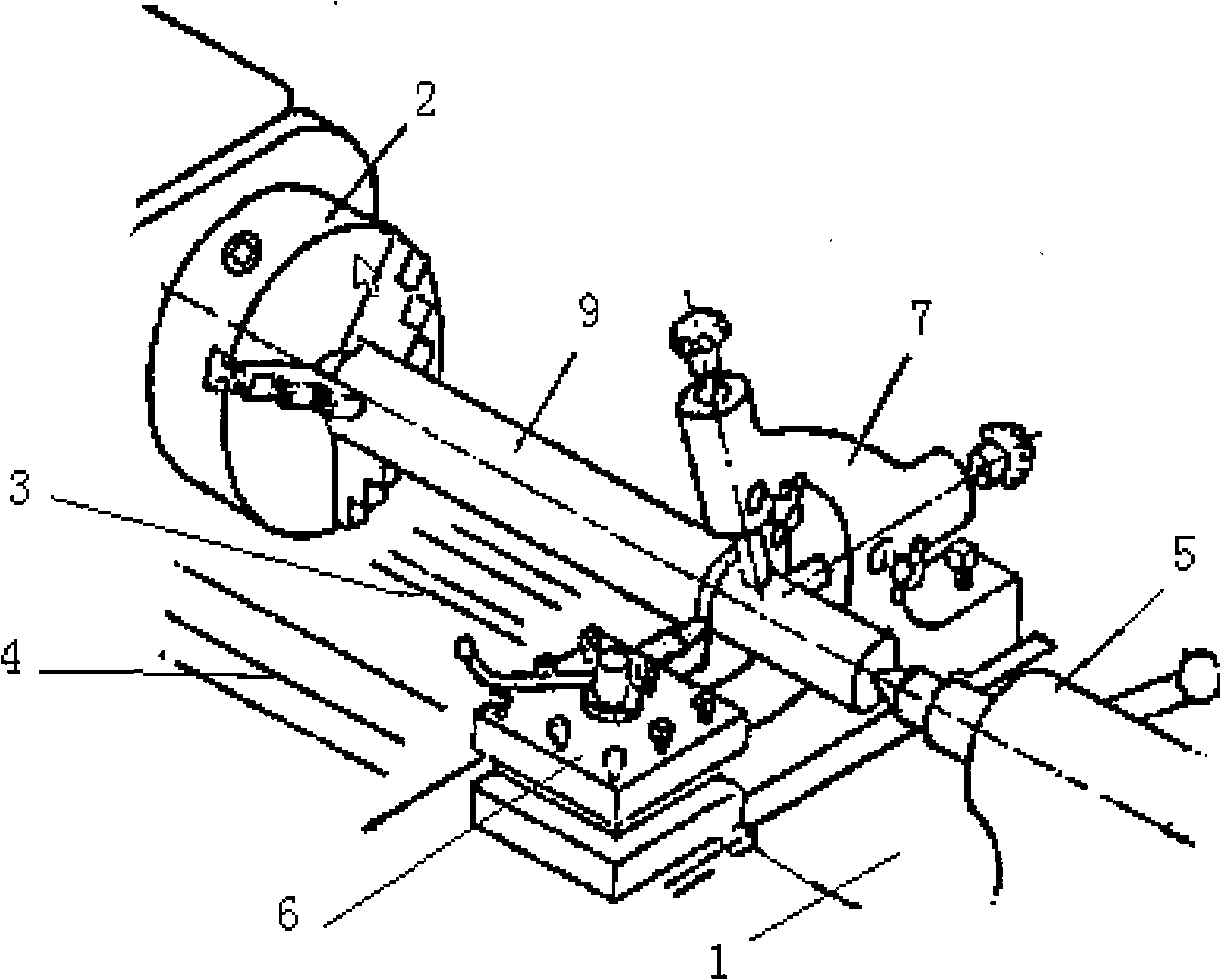

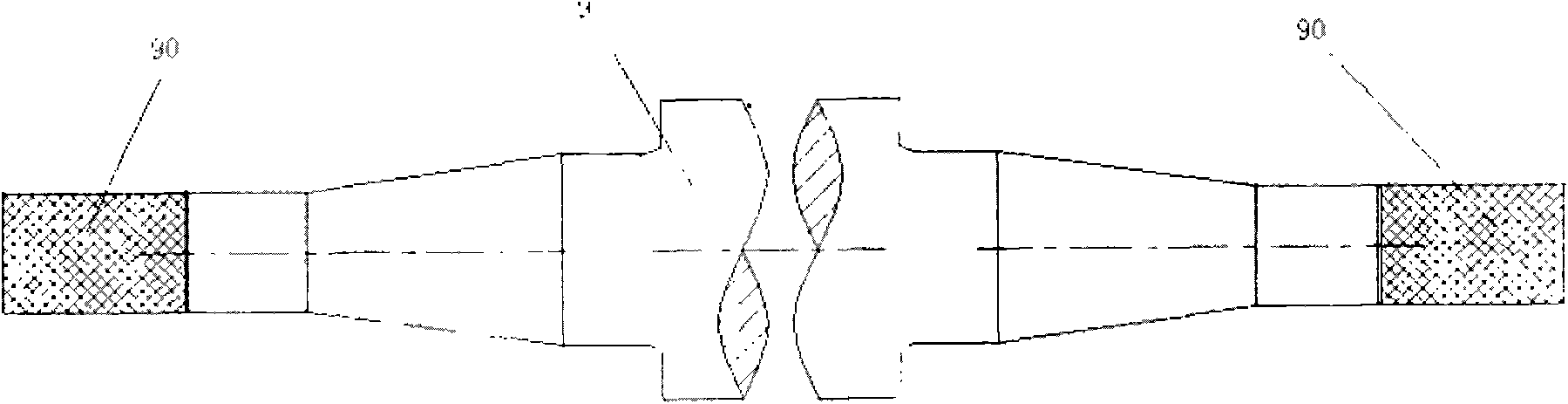

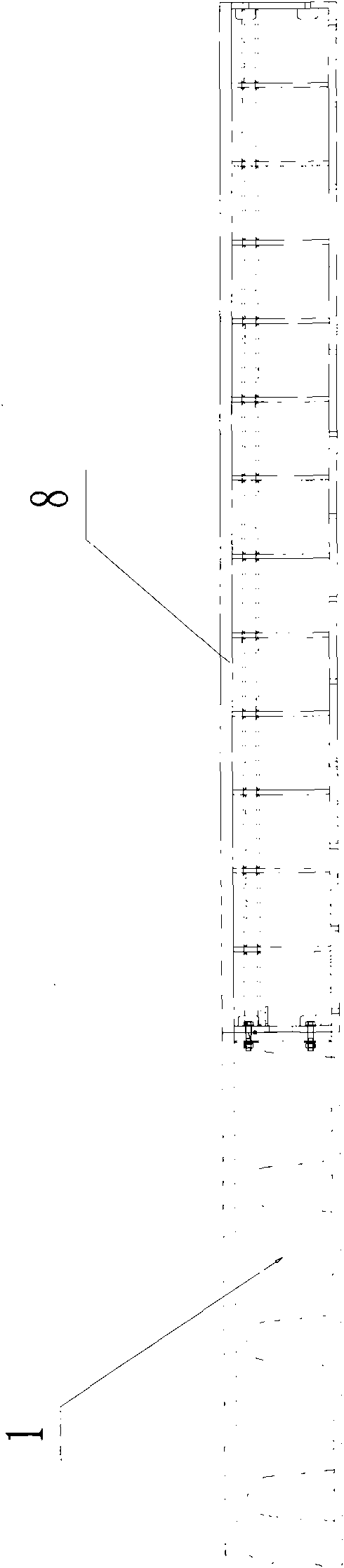

[0015] see Figure 1 to Figure 4 , a kind of machine tool of the present invention is used for processing the ultra-long-to-diameter ratio axis of super machine tool standard, comprises lathe bed 1, headstock 2, three tailstock guide rails 3, two tool rest guide rails 4, tailstock 5, tool rest 6 , a center frame 7, an additional tailstock guide rail 8 and an additional rack 80, wherein the headstock 2 is fixed on the front end of the bed 1 table; the three tailstock guide rails 3 are fixed on the front and rear of the bed 1 table along the spindle direction At the middle of the three tailstock guide rails 3, a gear rack 30 that can be engaged with the gear fixed at the bottom of the tailstock 5 is fixed on one of the middle ones; and parallel to each other on the table; the tail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com