Automatic welding machine

A technology of automatic welding machine and machine base, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low labor efficiency, low welding quality, and high labor intensity of manual welding, so as to improve product quality and improve The effect of production efficiency and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

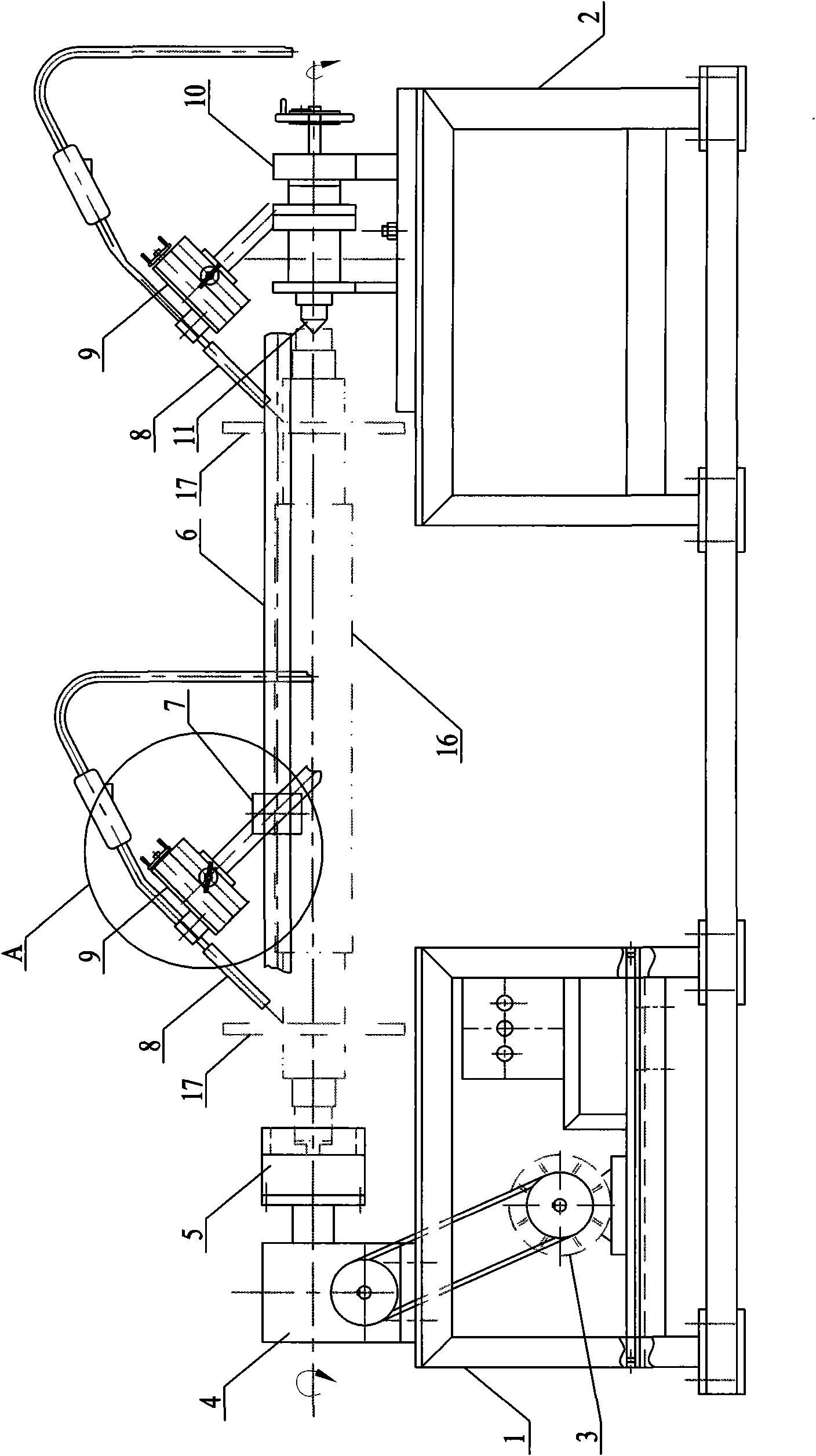

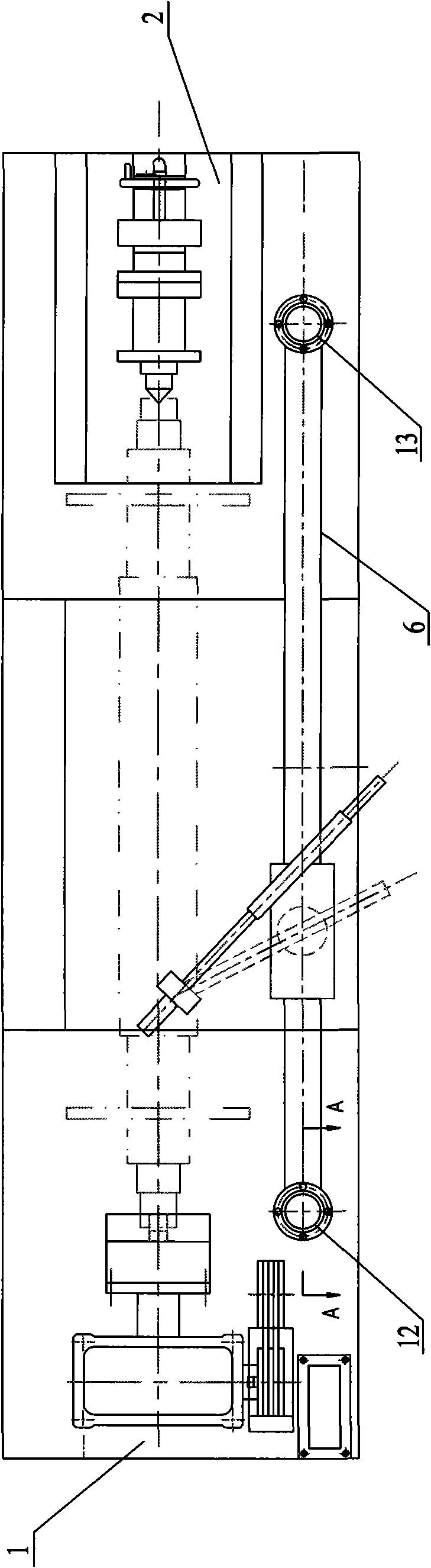

[0023] Such as figure 1 As shown, the automatic welding machine in this embodiment includes a first machine base 1 and a second machine base 2, and the two machine bases are arranged opposite to each other.

[0024] A variable speed motor 3 and a reduction box 4 are connected to the first base 1 , and the output end of the variable speed motor 3 is connected to the input end of the reduction box 4 . The output end of the reduction box 4 is connected with a chuck 5 .

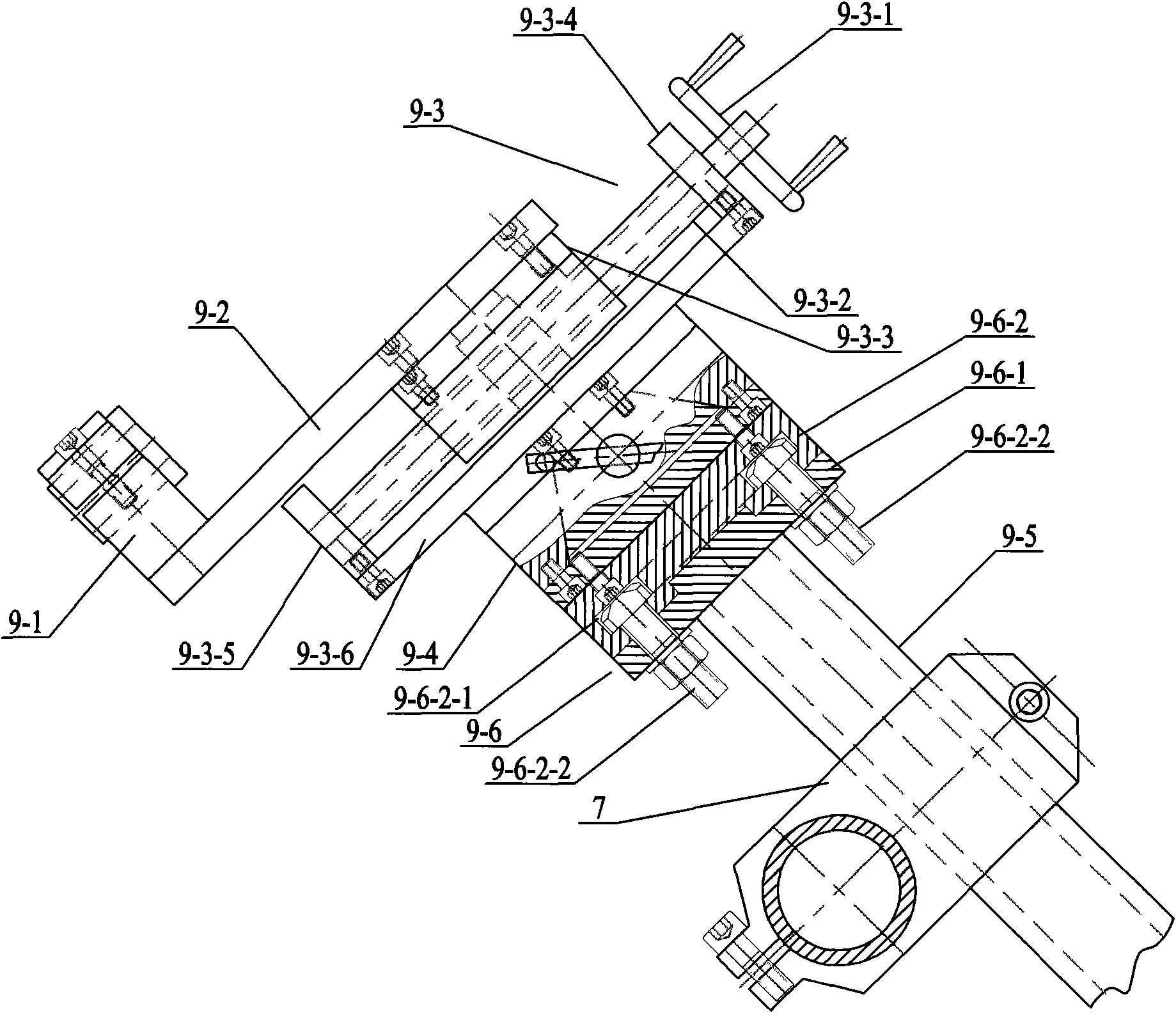

[0025] A support horizontal pipe 6 is spanned between the first support 1 and the second support 2, and two clamp joints 7 are connected on the support transverse pipe 6 ( figure 1 only one clamp fitting is shown). Each clip joint 7 is connected to a welding torch 8 at the same time. Each welding torch 8 is connected to the clip joint 7 by means of a welding torch adjustment seat 9 . A tailstock 10 is arranged on the second machine base 2 , and a movable center 11 is connected to the tailstock 10 , and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com