Multistage general angle self-adaptive blade three-coordinate measuring holder

A three-coordinate measurement and self-adaptive technology, applied in the direction of measuring devices, workpiece clamping devices, instruments, etc., can solve the problems of blade top damage, angular deviation, blade top deviation, etc., to achieve accurate positioning, convenient operation, The effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

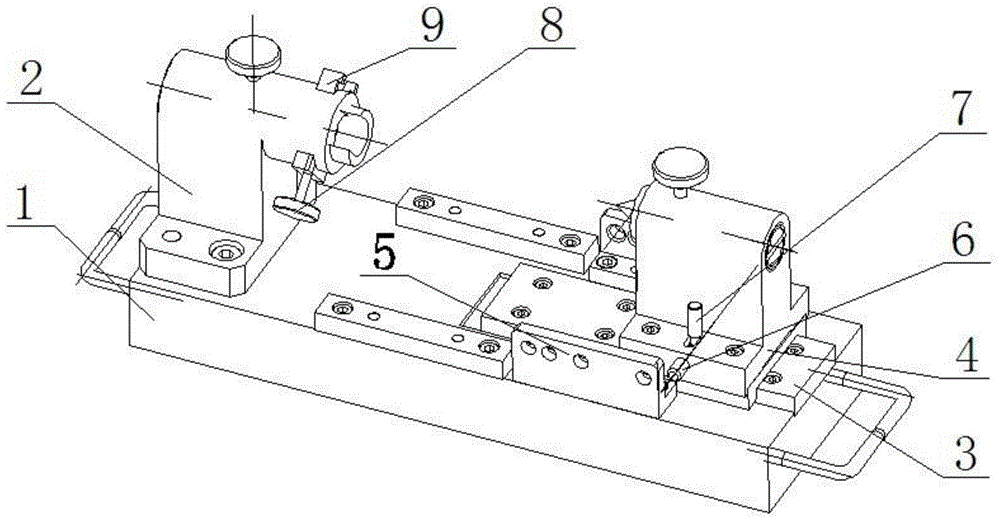

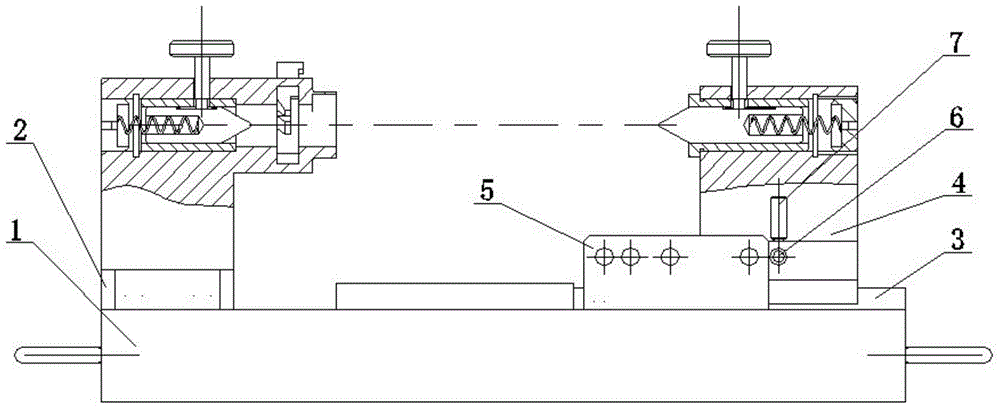

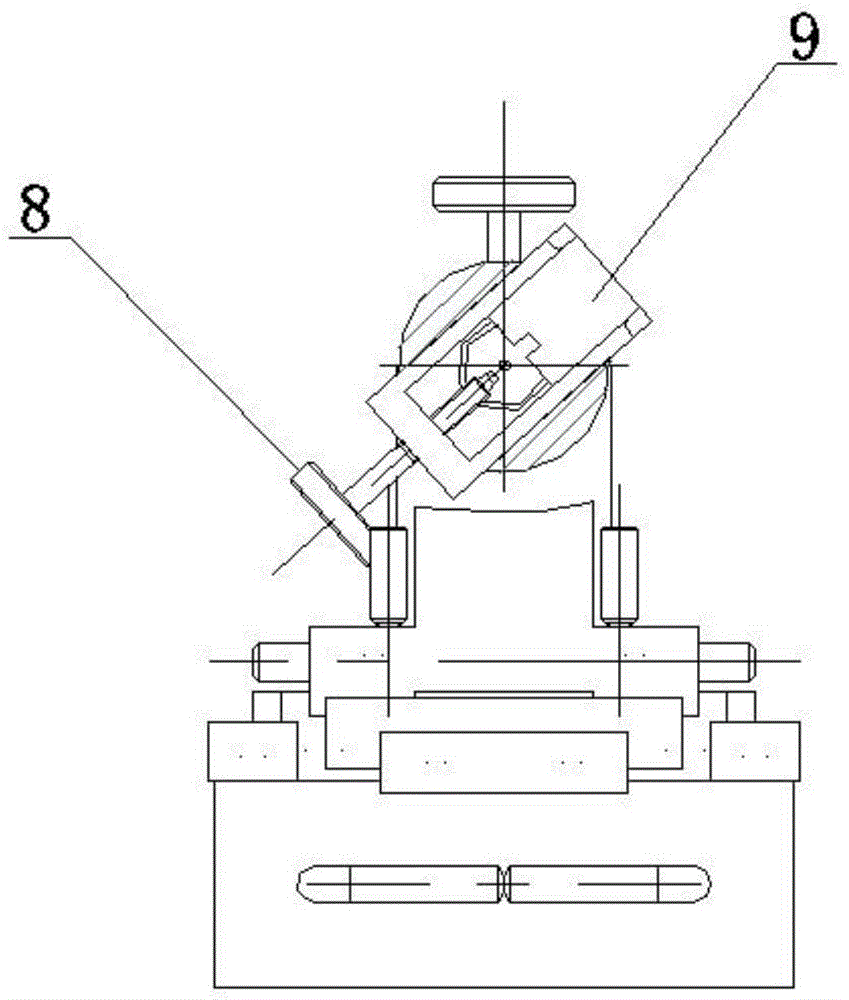

[0017] Such as figure 1 or figure 2 The shown multi-level universal angular self-adaptive blade three-coordinate measuring clamp base includes a base 1. A fixed top base 2 is provided on one side above the base 1. The fixed top base 2 is fixedly connected to the base 1, and the other A linear slide rail 3 fixedly connected to the base 1 is arranged along the axial direction of the blade 10. A sliding center seat 4 is arranged above the linear slide rail 3, wherein the first center of the fixed center seat 2 is connected to the sliding center The axis of the second center in the seat 4 is on the same straight line, and the sliding top seat 2 can move along the axial direction of the blade 10 by using the linear slide 3 to cooperate with the slideway provided at the bottom of the sliding center seat 4; Brackets 5 with limit holes are arranged on both sides of the linear slide 3, and at least one limit hole is provided on the bracket 5. The setting of multiple limit holes is to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com