Pipe jacking construction process for underneath pass road

A construction technology and road technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of shortening the construction period in the direction of pipe jacking, complicated pipe jacking construction technology, and many equipment and instruments To achieve the effect of shortening the construction period, improving the construction quality and simplifying the technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

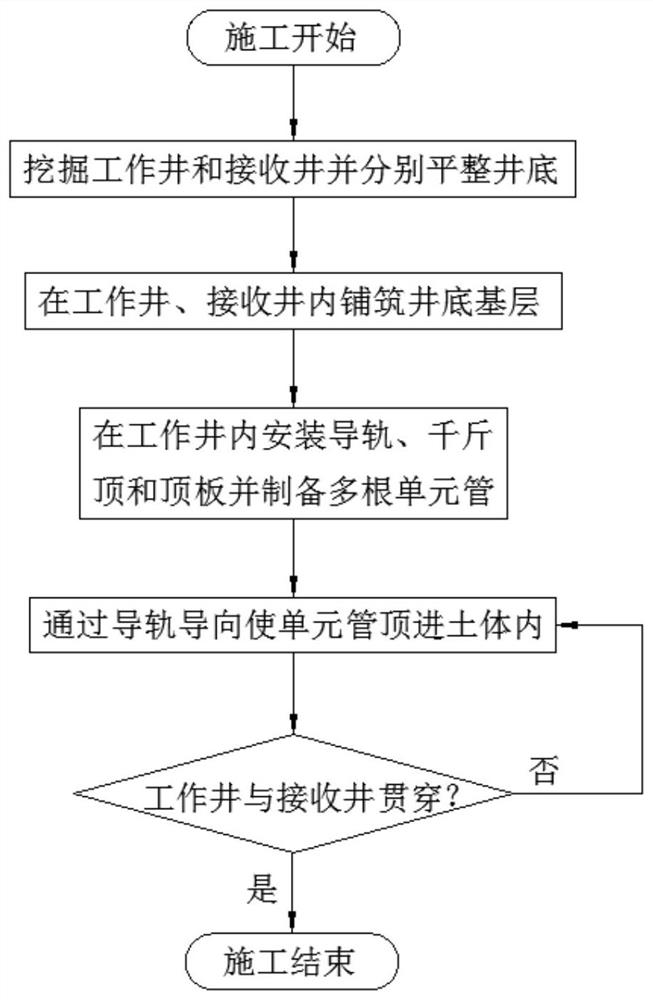

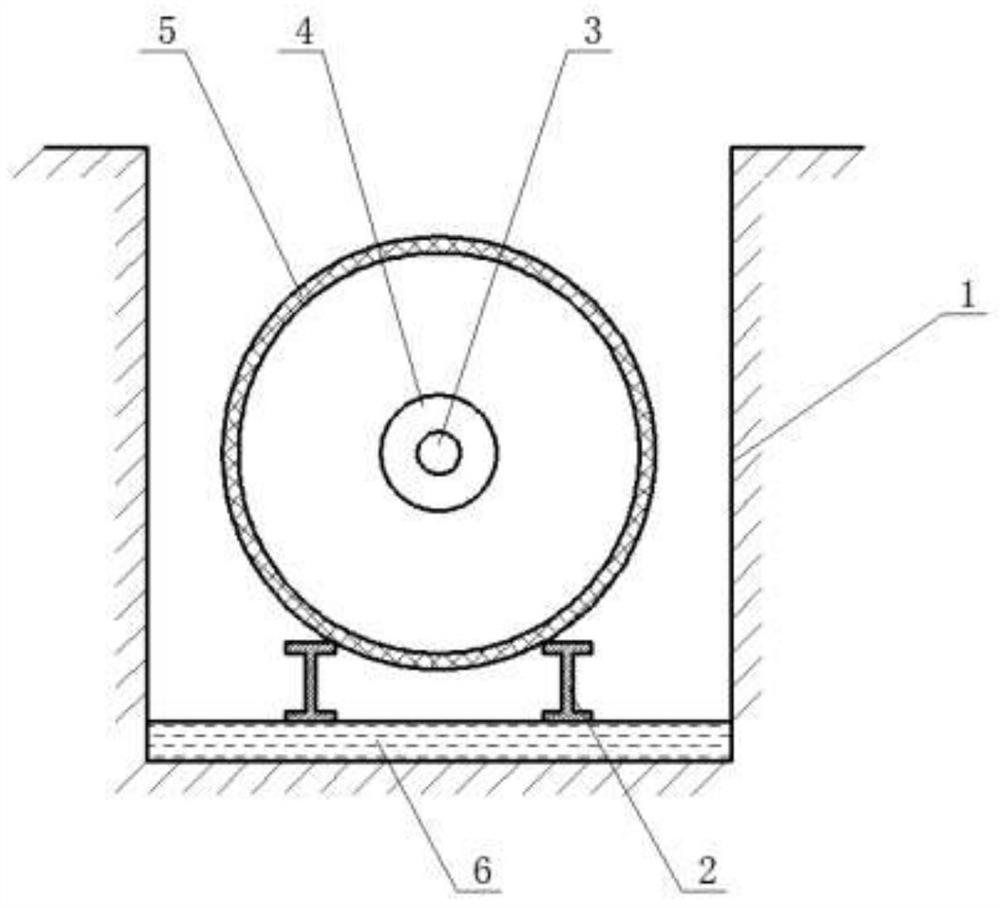

[0024] Such as figure 1 , figure 2 As shown, the present invention provides a kind of underpass road pipe jacking construction technology, comprises the following steps:

[0025] Step 1: Excavate earth on both sides of the road to form the working well 1 and the receiving well, and then level the bottom of the working well 1 and the receiving well;

[0026] Step 2: Install a pair of guide rails 2 at the bottom of the working well 1 in step 1. The pair of guide rails 2 are arranged parallel to each other with a distance of 1, and the height of the guide rails 2 is δ. Then install jacks 3 and 3 on the side of the working well 1 Arranged between the pair of guide rails 2 and the height of the jack 3 relative to the bottom of the working well 1 is H, and then a top plate 4 is installed on the piston rod of the jack 3, and several un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com