Novel electric cylinder

An electric cylinder and electric cylinder technology, which is applied in the direction of electric components, transmission devices, electromechanical devices, etc., can solve the problems that the electric cylinder cannot be miniaturized and the overall structure size is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

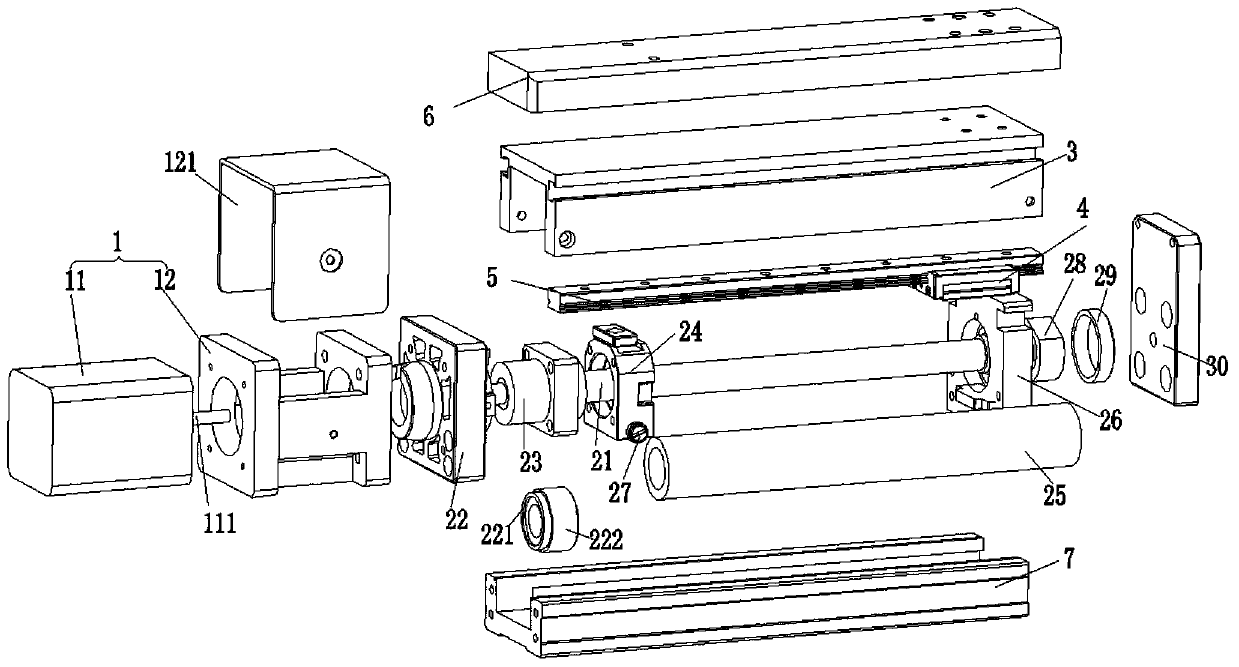

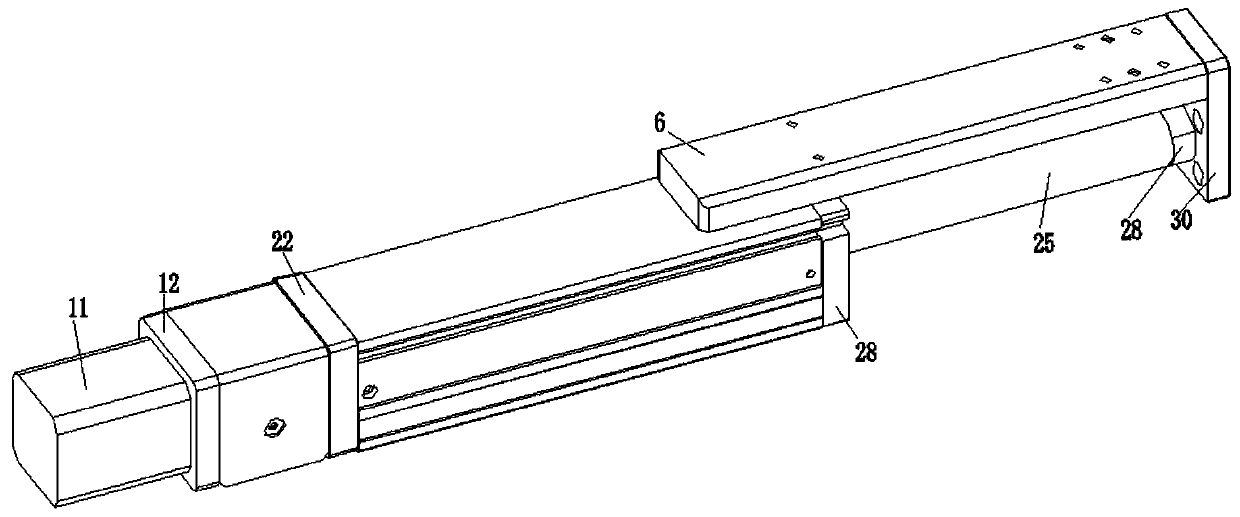

[0024] Such as Figure 1 ~ Figure 2 A new type of electric cylinder shown includes a power assembly 1 and a transmission assembly 2 connected to the output shaft 111 of the power assembly 1;

[0025] In a preferred embodiment of this embodiment, the transmission assembly 2 includes a screw rod 21 fixedly connected to the output shaft 111, a screw rod fixing seat 22 sleeved on one side of the screw rod 21, and a screw nut 23 threadedly connected to the screw rod 21 , Fix the nut fixing seat 24 sleeved on the screw nut 23, and the electric cylinder shaft 25 fixedly installed on the axial end of the nut fixing seat 24, and the electric cylinder support seat 26 sleeved on the other end of the electric cylinder shaft 25; nut fixing seat Fastening bolts 27 are installed on the left and right sides of 24.

[0026] In a preferred embodiment of this embodiment, the fastening bolt 27 is divided into a first fastening bolt 271 on the left side of the nut fixing seat 24 and a second fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com