A steel pipe nozzle correction device

A technology for calibrating equipment and nozzles, applied in the field of steel pipe nozzle calibrating equipment, can solve problems such as poor correction effect and complicated operation, and achieve the effects of preventing insufficient correction, accurate detection and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

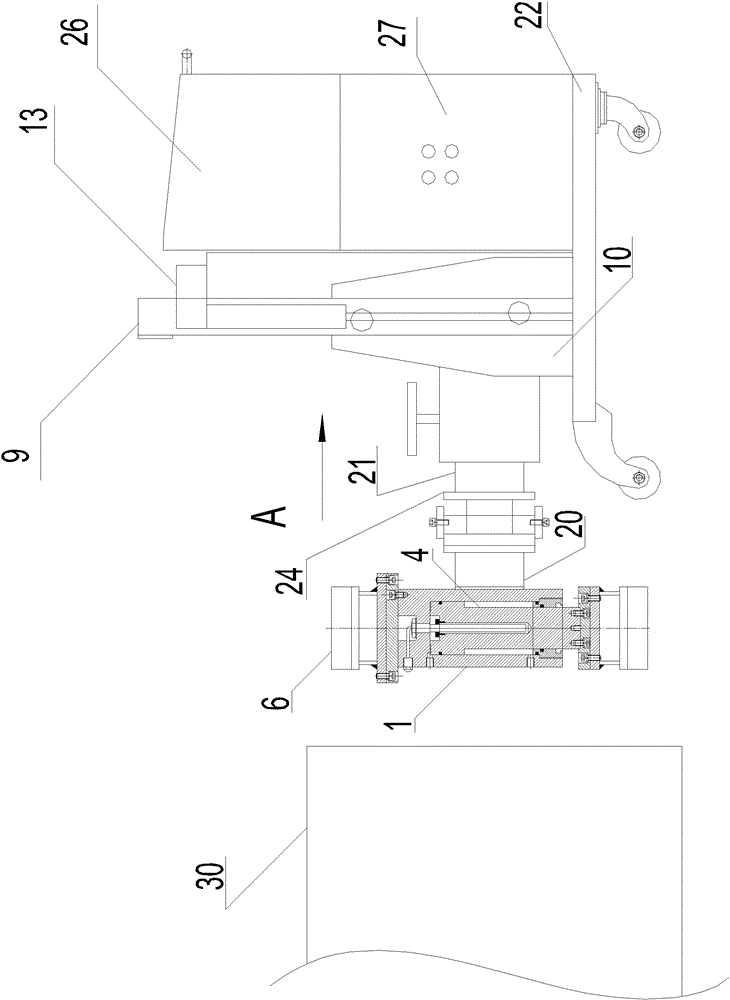

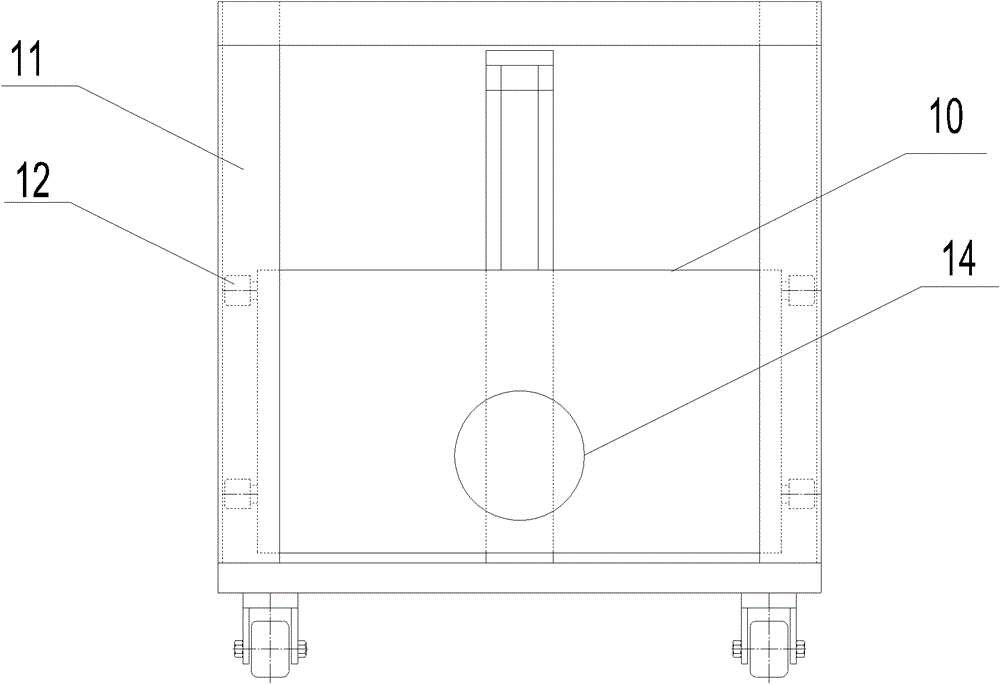

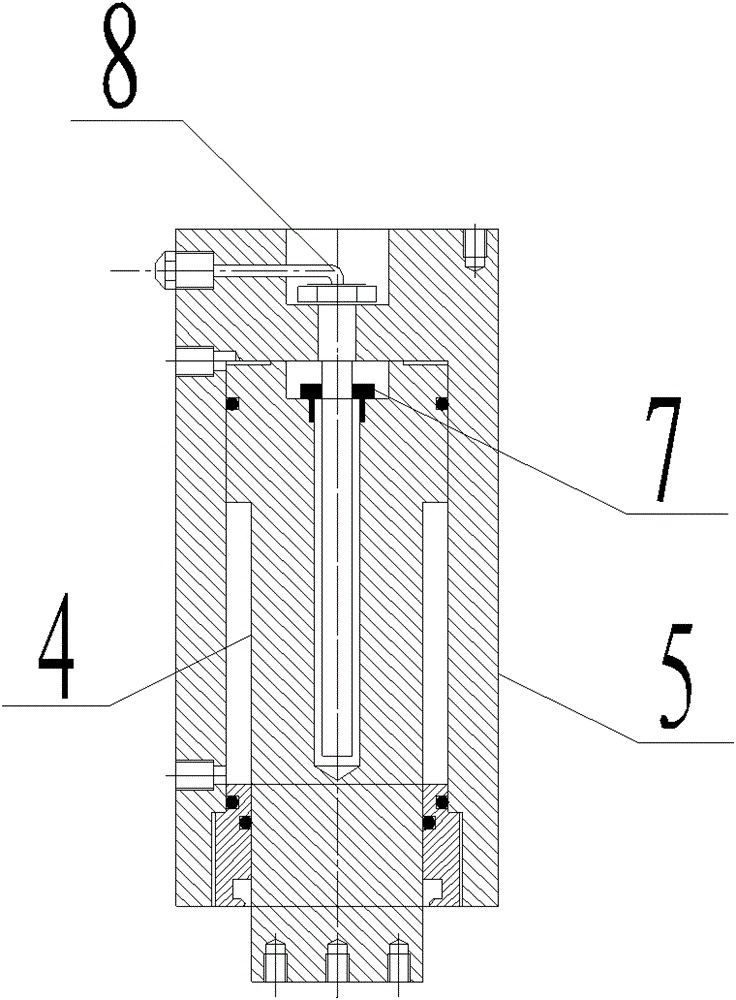

[0029] figure 1 It is a front view of a steel pipe nozzle correction device according to an embodiment of the present invention, figure 2 for figure 1 The lifting mechanism of the steel pipe nozzle correction equipment in figure 1 A view from direction A. Such as figure 1 As shown, a steel pipe nozzle correction device includes a correction hydraulic cylinder 1 that can extend into the steel pipe nozzle 30, a lifting mechanism that is connected with the correction hydraulic cylinder 1 and drives the correction hydraulic cylinder 1 to move up and down, and is used to control the The piston rod 4 of the correction hydraulic cylinder 1 is a control device (not shown) for the movement stroke along the axis perpendicular to the steel pipe nozzle 30. The control device is arranged in the control box 26, and the correction hydraulic pressure Cylinder 1 moves up and down under the drive of the lifting mechanism, and a floating compensation device that allows the cylinder body 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com