Small solid-phase tack producing device suitable for experimental laboratory and use method thereof

A solid-phase viscosity-increasing, laboratory-use technology, applied in the field of chemical fiber, can solve the problems of increasing molecular weight distribution and dispersibility, large device capacity, large volume, etc., to achieve uniform and stable product quality, high equipment charging coefficient, and compact equipment structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

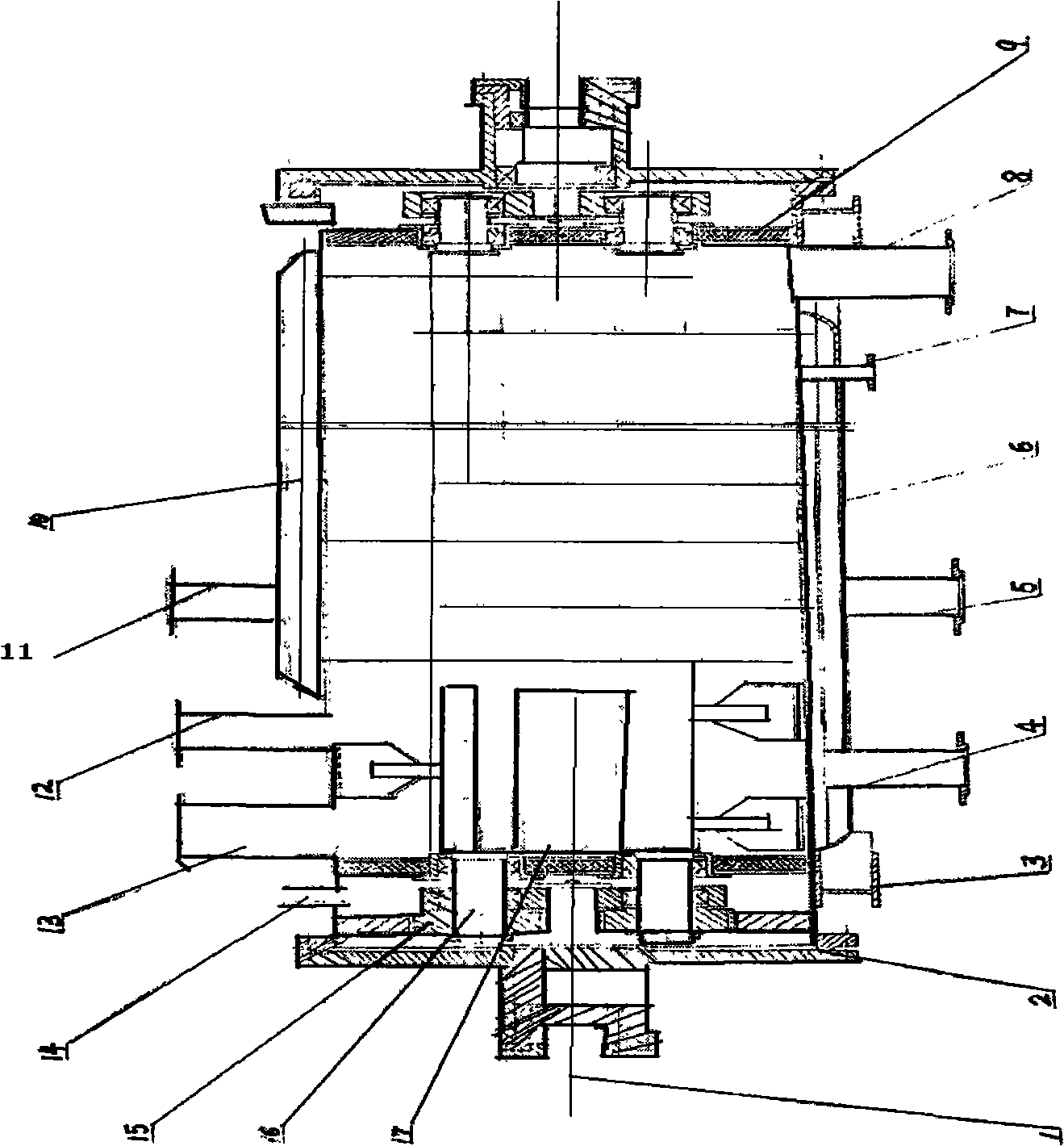

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 A small solid-phase thickening device is shown, and its specific structure is expressed as follows: there is a heating jacket 6 on the cylinder body 10, the biphenyl port 5 and 11 and the nitrogen inlet 4 are connected to the jacket 6, and the inlet port 4 is connected to the cylinder body. Material port 13, discharge port 8, vacuum port 12 and sampling port 7, two stirring shafts 16 are installed in the cylinder, stirring blades 17 are installed on the stirring shaft 16, and two ends of the cylinder are equipped with The driven planetary gear transmission system 15 is also connected with the stirring shaft 16. The two ends of the stirring shaft are fixed with heat shields 9 to isolate the material in the cylinder from the outside world. The two ends of the cylinder body 10 are fixed and closed with flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com