Three-stage suspension roasting-magnetic separation method for hematite-limonite mixed iron ores

A suspension roasting, iron ore technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of poor sorting index, asynchronous reaction, inconsistent properties of iron ore, etc., to ensure the uniformity of reduction , Efficient recycling, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The main components of the red-brown mixed iron ore (hematite-limonite mixed ore) are shown in Table 1 (unit wt%);

[0046] components TF FeO SiO 2 al 2 o 3 CaO content 35.25 1.03 49.41 0.15 0.39 components MgO P S K Na content 0.37 0.88 0.05 0.04 0.03

[0047] The chemical phase analysis results are shown in Table 2;

[0048] Table 2

[0049]

[0050] The method proceeds as follows:

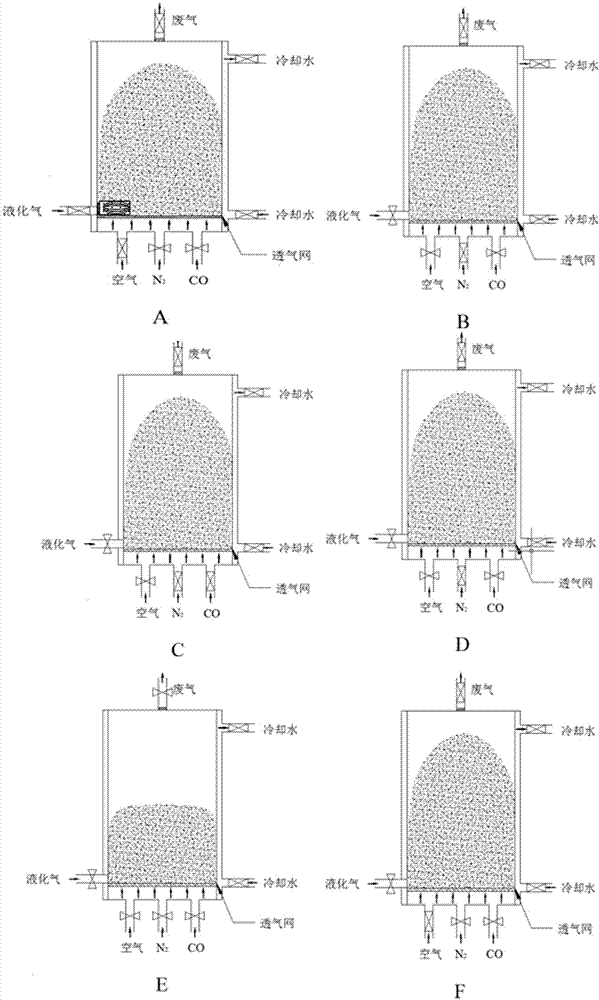

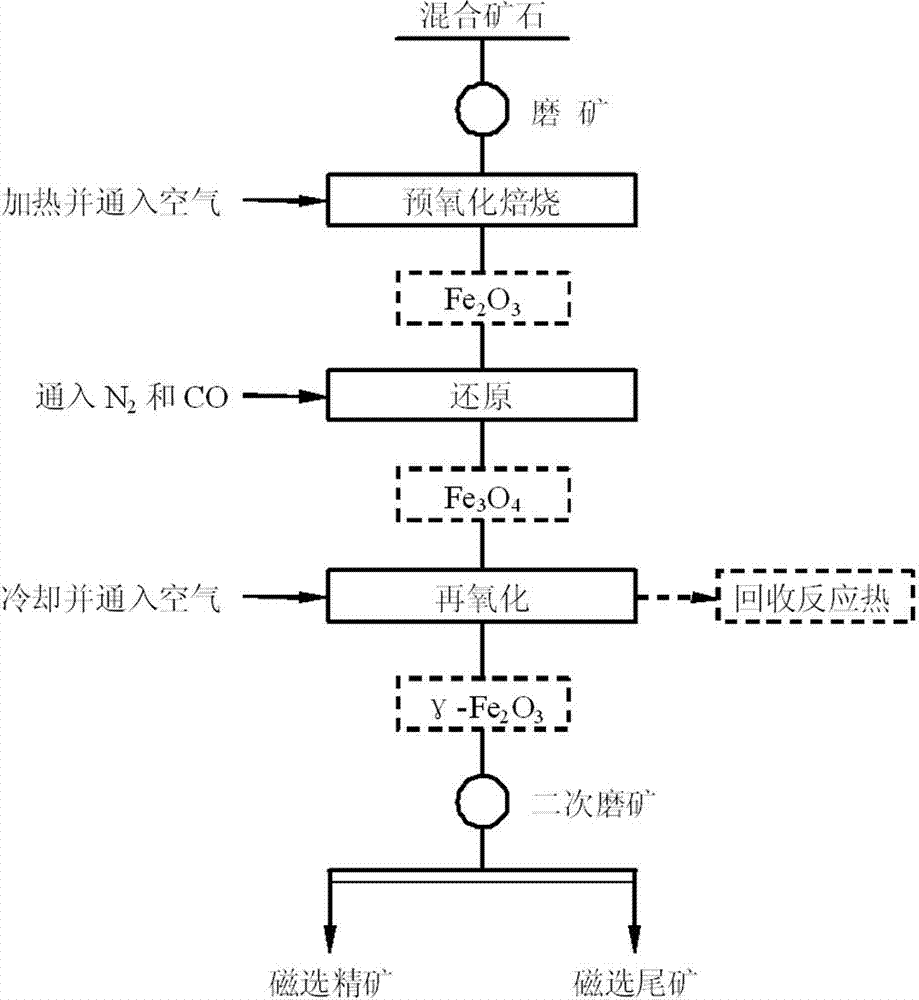

[0051] 1. Pre-oxidation: Grind the red-brown mixed iron ore until the particle size is -0.074mm, accounting for 40% of the total weight, then put it into the suspension reaction furnace, and feed air into the suspension reaction furnace to make the material in a suspended state; The material in the suspension reaction furnace is heated to 800°C for pre-oxidation and roasting. At this time, the suspension reaction furnace is an oxidizing atmosphere, and the pre-oxidation time is 10s; the red-brown mixed iron ore is hematite-l...

Embodiment 2

[0058] Russet mixed iron ore grade 39% iron, containing 3% FeO, SiO by weight 2 15%;

[0059] Method is with embodiment 1, and difference is:

[0060] (1) Grind the ore until the particle size -0.074mm accounts for 50% of the total weight, heat to 700°C for pre-oxidation roasting, and the pre-oxidation time is 30s;

[0061] (2) The reduction time is 10 seconds; the volume flow ratio of CO and nitrogen is 1:5;

[0062] (3) When the temperature drops to 350°C, air is introduced into the suspension reaction furnace for reoxidation; the main component of the reoxidized material is magnetic iron γ-Fe 2 o 3 and Fe 3 o 4 ; where γ-Fe 2 o 3 The weight content is 80%, Fe 3 o 4 The weight content is 12%;

[0063] (4) When the part of the material after the second grinding to the particle size -0.044mm accounts for 50% of the total weight, the material after the second grinding is subjected to magnetic separation under the condition of a magnetic field strength of 70kA / m; the...

Embodiment 3

[0065] Russet mixed iron ore grade 33% iron, containing 4% FeO, SiO by weight percentage 2 20%;

[0066] Method is with embodiment 1, and difference is:

[0067] (1) Grind the ore until the particle size -0.074mm accounts for 60% of the total weight, heat to 600°C for pre-oxidation roasting, and the pre-oxidation time is 60s;

[0068] (2) The reduction time is 30 seconds; the volume flow ratio of CO and nitrogen is 1:3;

[0069] (3) When the temperature drops to 300°C, air is introduced into the suspension reaction furnace for reoxidation; the main component of the reoxidized material is magnetic iron γ-Fe 2 o 3 and Fe 3 o 4 ; where γ-Fe 2 o 3 The weight content is 60%, Fe 3 o 4 The weight content is 31%;

[0070] (4) When the part of the material after the secondary grinding to the particle size -0.044mm accounts for 60% of the total weight, the material after the secondary grinding is subjected to magnetic separation under the condition of a magnetic field streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com